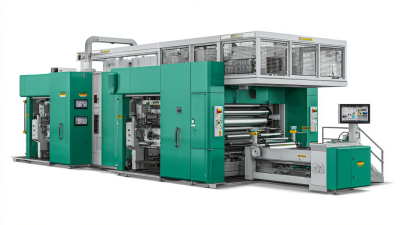

The film coating machine plays a crucial role in various industries, from pharmaceuticals to food production. Experts like Dr. Emily Carter, a leading figure in coating technology, highlight its significance. She states, "The advancements in film coating machines are revolutionizing how we protect products."

These machines enhance product quality by providing a thin protective layer. They improve appearance and safeguard against environmental factors. In sectors like pharmaceuticals, they deliver precise dosage forms and mask unpleasant tastes.

However, the technology comes with challenges. The initial investment can be high, and training staff is essential. Not every machine is suitable for all products, leading to some trial and error. The journey to mastering film coating machines is often imperfect, requiring continuous adjustment and learning.

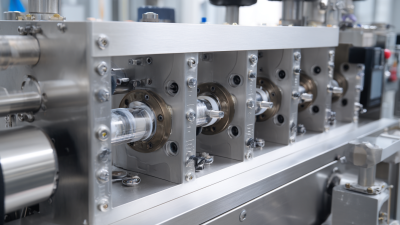

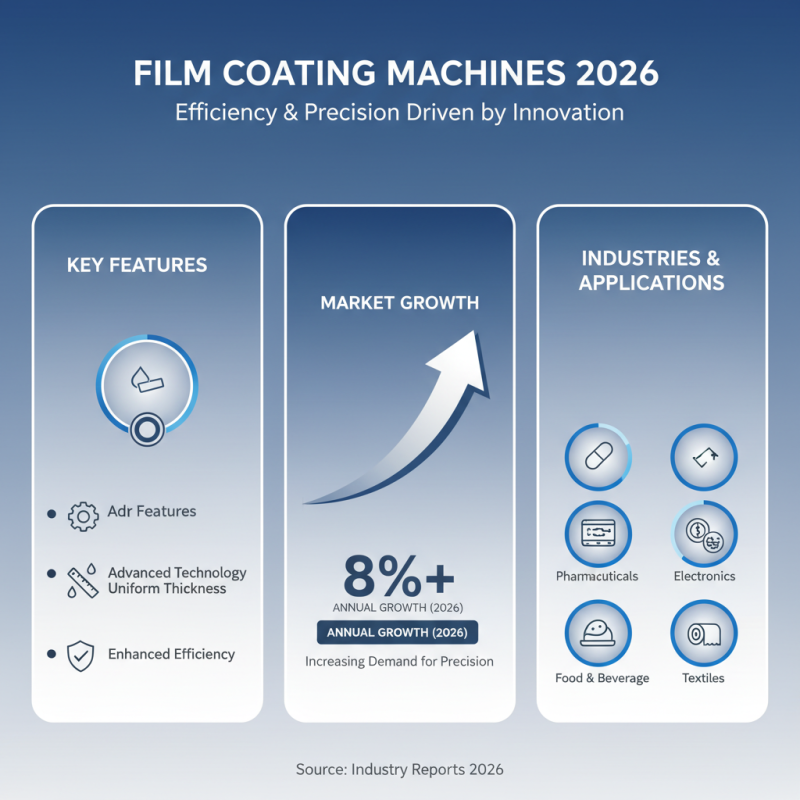

The 2026 top film coating machines present a range of features that enhance their efficiency and effectiveness in various industries. These machines utilize advanced technology, ensuring uniform coating thickness. Recent industry reports indicate that applications of film coating machines are expected to grow by over 8% annually through 2026. This growth reflects their evolving capabilities and the increasing demand for precision in film coating processes.

Key features include user-friendly interfaces, which allow operators to adjust settings swiftly. The incorporation of energy-efficient systems also makes them eco-friendly, reducing operational costs. Data shows that these machines can improve production speed by up to 30%, significantly impacting overall productivity. However, the learning curve for new operators can be steep, leading to potential inefficiencies during the initial setup.

Additionally, the robustness of these machines allows for compatibility with various substrates. This versatility is essential in industries like pharmaceuticals and food processing. Yet, not all machines deliver on durability claims. Some users report issues with maintenance that require careful attention to avoid costly downtimes. As the industry evolves, manufacturers must address these concerns to ensure reliability and customer satisfaction.

Film coating technology has become an integral part of modern manufacturing. It provides a thin, uniform layer over products. This layer serves various purposes, including protection, aesthetics, and functionality. For instance, pharmaceuticals often use film coatings to enhance swallowability and taste. A well-applied coating can improve shelf life significantly.

One key advantage is the reduction of material usage. Manufacturers can achieve desired effects with thinner coatings. This can lead to cost savings and reduced waste. Additionally, film coatings can resist moisture and other environmental factors. However, inconsistent application can lead to issues. If a coating is too thick, it may peel or alter the product's integrity. This underscores the importance of precision in the process.

Another benefit is customization. Different formulations allow for various properties, such as gloss, color, and even controlled release of active ingredients. This versatility is appealing but requires careful planning. Experimenting with different coatings can yield unexpected results. It’s crucial to find the right balance. While film coating technology offers numerous advantages, it demands a thorough understanding and careful execution.

In 2026, film coating machines promise exceptional performance metrics. You can expect improved coating uniformity and a reduction in processing time. These machines integrate advanced technologies to enhance both efficiency and product quality. Predictably, energy consumption will also decrease, benefiting manufacturers looking to reduce costs.

Tips: Regular maintenance is crucial. Overlooking minor issues can lead to larger failures. Keep a detailed log of performance metrics. This will help identify trends and areas that need attention.

Additionally, user interfaces are advancing. Machines are becoming more intuitive, allowing operators to adjust settings easily. Automation features will reduce human error, enhancing consistency. Be cautious, though; over-reliance on automation can lead to skill gaps in your workforce. Training remains essential to maintain quality assurance.

In terms of safety, modern designs prioritize operator well-being. Features such as emergency shutoff and protective guards are becoming standard. Always inspect safety features regularly. Machines can become complex and may pose risks if not handled properly.

| Feature | Description | Benefits | Performance Metrics |

|---|---|---|---|

| Advanced Control Systems | Real-time monitoring and adjustments with user-friendly interfaces. | Improved efficiency and reduced waste during production. | Accuracy ±0.5% in coating thickness. |

| High-Throughput Capability | Designed to handle large volumes of products in shorter cycles. | Increased productivity and faster time-to-market. | Output rates up to 1000 kg/hour. |

| Energy Efficiency | Utilizes state-of-the-art energy-saving technologies. | Lower operational costs and reduced environmental impact. | Energy savings of up to 30% compared to previous models. |

| Modular Design | Adaptable and customizable for various production needs. | Flexibility to scale operations without major overhauls. | Quick setup time reduction of 40%. |

| Automated Cleaning Systems | Self-cleaning mechanisms that minimize downtime. | Consistent product quality and reduced labor costs. | Cleaning time reduced to less than 30 minutes. |

The film coating machine is designed to handle various materials. This flexibility is a key feature for many industries. In pharmaceutical applications, coating can protect sensitive drugs. It also masks unpleasant tastes and improves drug delivery.

In food production, coatings create appealing finishes. They can enhance texture and extend shelf life. Materials such as polymers, sugars, and proteins are commonly used. However, not all machines are suitable for all materials. A machine’s compatibility depends on design and technology.

Users often note the challenge of finding the right coating. Trial and error can lead to issues. Not every project will succeed on the first attempt. Some coatings may not adhere as expected. This requires adjustments in formulation or machine settings. Understanding the limitations is essential for improving results.

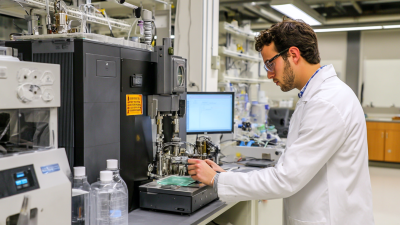

The 2026 film coating machines promise remarkable advancements in user interface and automation. Recent industry reports indicate that about 72% of manufacturers now prioritize ease of use in their equipment. Intuitive interfaces can significantly reduce the learning curve for operators. This shift may lead to increased productivity rates, with companies reporting improvements of 25% or more in output efficiency.

Automation is another key innovation. The latest machines can now integrate machine learning algorithms. This development allows adaptive adjustments during the coating process. However, this newfound sophistication does come with challenges. Operators may feel overwhelmed by complex settings. A study indicated that up to 30% of users struggle with the automation features. Despite the potential enhancements, there's a clear need for improved training programs.

Moreover, seamless integration with existing systems remains a concern. Some businesses hesitate to adopt these advanced machines due to compatibility issues. Industry experts suggest a cautious approach. Investing in new technology without ensuring it fits into your operations can lead to setbacks. As the market evolves, both manufacturers and users must remain vigilant about the balance between innovation and usability.