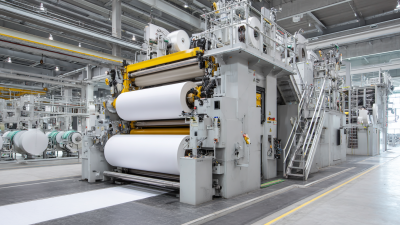

In today’s competitive business environment, the efficiency and quality of production processes are paramount. One innovation that has significantly transformed the paper industry is the Paper Coating Machine. According to John Smith, a renowned expert in paper manufacturing technology, “Investing in a Paper Coating Machine not only enhances product quality but also streamlines production workflows.” This statement captures the essence of why businesses, big and small, are increasingly turning to such machines to remain competitive.

The advantages of using a Paper Coating Machine are multifaceted. Firstly, it allows for uniform application of coatings, which significantly improves the aesthetic and functional properties of paper products. Secondly, the high-speed capabilities of these machines enable companies to meet increasing demand without compromising on quality. Additionally, a Paper Coating Machine can also improve cost-efficiency by reducing waste and optimizing material usage. As the industry continues to evolve, understanding these benefits is crucial for businesses aiming to enhance their production capabilities and maintain a competitive edge in the market.

Implementing a paper coating machine in your production line can bring numerous advantages that enhance both quality and efficiency.

One significant benefit is the improved durability of the paper products produced. Coating adds a layer of protection, making the papers resistant to moisture, oil, and other environmental factors.

This not only prolongs the shelf life of the products but also ensures that they maintain their aesthetic appeal over time.

Another key advantage is the enhanced printability of coated papers. With a smoother and more refined surface, these papers provide better ink adhesion, resulting in vibrant colors and sharp details in printed materials.

This is particularly beneficial for businesses looking to produce high-quality marketing materials or packaging that grabs attention.

Tips: When considering the integration of a paper coating machine, evaluate the types of coatings that best suit your products.

Opt for a coating that aligns with your end-use requirements—whether for gloss, matte finish, or functionality like UV resistance.

Additionally, regular maintenance of the machine can prevent downtimes and ensure consistent production quality.

Investing in the right technology not only streamlines processes but also positions your business to meet growing market demands effectively.

The use of paper coating machines is becoming increasingly pivotal for businesses aiming to enhance product durability. Advanced coating techniques allow for improved resistance to moisture, UV light, and physical wear, ensuring that products maintain their quality over time. According to a report by Smithers Pira, the global demand for coated paper is expected to reach 36 million tons by 2025, illustrating the growing recognition of the importance of protective coatings in various industries.

Utilizing a paper coating machine significantly boosts the lifespan of products. Coated papers tend to show reduced fading and discoloration, resulting in longer-lasting visual appeal for packaging and printed materials. In fact, studies show that products displayed with coated paper can experience up to a 25% increase in their shelf life, which translates into heightened customer satisfaction and decreased waste.

Tips: When selecting a coating technique, consider the environment in which the product will be used. For outdoor applications, UV-resistant coatings can be beneficial, while moisture barriers are vital for products subjected to humidity. Additionally, regularly evaluating your coating processes can lead to improvements in efficiency, reducing operational costs while enhancing product performance.

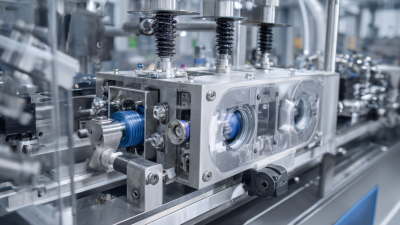

In the competitive landscape of print production, achieving superior print quality and consistency is paramount for businesses seeking to differentiate themselves. A paper coating machine plays a crucial role in this aspect by applying specialized coating solutions that enhance the appearance and durability of printed materials. According to a report by Smithers Pira, the global market for printed products is projected to grow significantly, and firms that leverage advanced coating technologies can expect to see an insurance against quality issues, elevating their output to meet the demands of discerning clients.

One of the key benefits of utilizing a paper coating machine is the ability to enhance color vibrancy and clarity. When coatings such as gloss, matte, or satin are applied, they create a protective layer that not only improves the visual appeal but also helps in achieving consistent color reproduction across batches. This consistency is further supported by a study published in the International Journal of Printing Technology, which highlighted that coated papers used for high-quality printing could reduce color variation by as much as 30%, ensuring that every print meets the highest standards.

Moreover, the application of coatings significantly increases the longevity of printed materials, making them resistant to factors such as fading and smudging. By incorporating such innovations, businesses can reduce waste and reprints, ultimately optimizing their production processes. The investment in state-of-the-art paper coating machines is not merely about enhancing print quality; it is a strategic move that solidifies a company's reputation for excellence in the ever-evolving print industry.

The integration of a paper coating machine into your business operations can significantly enhance cost-effectiveness, particularly through automation. One of the foremost advantages is the reduction of labor costs associated with manual coating processes. By automating these tasks, businesses can redirect their workforce towards more strategic activities, allowing for better resource utilization and improved productivity. This shift not only minimizes the need for extensive labor but also reduces the potential for human error, leading to higher-quality outputs and less waste.

Moreover, a paper coating machine streamlines production processes, resulting in time savings that contribute to overall cost efficiency. Automated systems can operate at a much faster pace than manual methods, enabling companies to meet higher demand without needing to expand operational hours. This acceleration aligns perfectly with just-in-time manufacturing practices, helping businesses maintain lean inventories and avoid the costs associated with overproduction. In the long term, these time savings translate into significant financial benefits, providing a substantial return on investment as businesses optimize their operational capacities.

The global demand for coated paper products has been steadily increasing, driven by various industries seeking enhanced printing capabilities and improved product presentation. According to a recent report by Smithers Pira, the coated paper market is expected to grow at a CAGR of 4.2% from 2021 to 2026, reflecting a shift towards higher-quality, specialized paper applications. Businesses leveraging advanced paper coating machines can capitalize on this trend by diversifying their product offerings, meeting the evolving needs of various sectors such as packaging, publishing, and promotional materials.

By employing a state-of-the-art paper coating machine, companies can expand their range of applications, including water-resistant finishes, gloss, and matte coatings. This versatility allows for customization and differentiation in a crowded marketplace. The ability to produce specialty coated papers can open new revenue streams, tapping into niche markets such as eco-friendly packaging or high-end publications. As reported by Technavio, the rise of e-commerce and environmental awareness is propelling the demand for sustainable and high-performance paper products, emphasizing the importance of adopting innovative coating technologies to stay competitive.

This chart displays the top five advantages of using a paper coating machine for your business, rated on a scale from 1 to 10. Leveraging these advantages can significantly expand market opportunities and enhance the quality of your paper products.