The utilization of Hot Melt Coating Machines in modern manufacturing processes has proven to be a transformative advancement, enhancing efficiency and product quality across various industries. According to recent reports by industry analysts, the global hot melt adhesives market is projected to reach $11.3 billion by 2026, reflecting a compound annual growth rate (CAGR) of 6.2% from 2021 to 2026. This growth is indicative of the increasing reliance on hot melt technologies, which are renowned for their rapid solidification and superior bonding capabilities. The Hot Melt Coating Machine not only streamlines production workflows but also offers the versatility required for a wide range of applications—from automotive and packaging to textiles and electronics. As manufacturers continue to seek cost-effective solutions without compromising on performance, the integration of Hot Melt Coating Machines will likely play a pivotal role in driving innovation and competitive advantage in the manufacturing sector.

The utilization of Hot Melt Coating Machines in modern manufacturing processes has proven to be a transformative advancement, enhancing efficiency and product quality across various industries. According to recent reports by industry analysts, the global hot melt adhesives market is projected to reach $11.3 billion by 2026, reflecting a compound annual growth rate (CAGR) of 6.2% from 2021 to 2026. This growth is indicative of the increasing reliance on hot melt technologies, which are renowned for their rapid solidification and superior bonding capabilities. The Hot Melt Coating Machine not only streamlines production workflows but also offers the versatility required for a wide range of applications—from automotive and packaging to textiles and electronics. As manufacturers continue to seek cost-effective solutions without compromising on performance, the integration of Hot Melt Coating Machines will likely play a pivotal role in driving innovation and competitive advantage in the manufacturing sector.

When selecting the right hot melt coating machine for your manufacturing needs, it’s essential to consider several factors that can significantly affect production efficiency and product quality. According to industry reports, the global hot melt adhesives market is projected to reach USD 10.6 billion by 2025, indicating a growing reliance on these technologies within various sectors, including pharmaceuticals, packaging, and automotive. Hot melt coating machines facilitate uniform application, reducing material wastage and improving bonding quality, thereby enhancing overall productivity.

Moreover, modern hot melt coating machines come with advanced features such as temperature control, adjustable application rates, and integrated monitoring systems. These features not only ensure precision in coating but also adapt to the specific requirements of different substances and applications. For instance, in the pharmaceutical industry, where pelletization is gaining traction for drug formulation and delivery, having a reliable hot melt coating machine can enable manufacturers to achieve a controlled release profile, enhancing therapeutic effectiveness. With continuous innovations in machine technology, manufacturers must carefully evaluate their specific processes and production goals to choose the ideal equipment that meets their operational requirements.

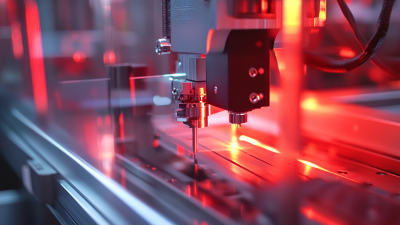

Hot melt coating machines have become an essential component in modern manufacturing processes, particularly in industries such as automotive, woodworking, and electronics. Understanding how hot melt coating works can enhance productivity and product quality. The process involves applying a thermoplastic adhesive in a molten state, which cools quickly to create a strong bond. This method not only accelerates production but also minimizes waste, making it an efficient choice for various applications.

In the automotive sector, hot melt coatings are utilized for their durability and ability to withstand extreme conditions. Meanwhile, in woodworking, they provide a reliable way to bond materials without the need for clamping. For electrical and electronic applications, the precision of hot melt coatings ensures that components are securely affixed, thereby enhancing reliability. The packaging industry benefits as well, with hot melt adhesives facilitating swift and secure packaging solutions.

**Tips:** When considering hot melt coating for your production line, ensure the adhesive is suitable for your specific materials to optimize performance. Additionally, regular maintenance of coating machines can prevent downtime and extend their lifespan, ultimately contributing to a more streamlined manufacturing process.

Hot melt coating machines are revolutionizing modern manufacturing processes across various industries. One of the key advantages is their ability to provide a seamless application of coating materials, which enhances product performance and durability. Industries such as automotive, electronics, and packaging benefit significantly from the precision and efficiency of hot melt coatings. These coatings not only improve adhesion but also offer protection against moisture and environmental factors, ensuring that products maintain their integrity over time.

Tip: When considering hot melt coating applications, it's essential to evaluate the specific type of adhesive used. Different formulations can offer varying levels of flexibility, temperature resistance, and bonding strength, catering to the unique needs of different industries.

Another notable benefit is the reduction in waste and increased productivity. Hot melt coating processes are highly efficient, allowing for rapid application and quicker cure times compared to traditional methods. This efficiency leads to reduced downtime and greater output, making it an attractive option for manufacturers looking to streamline operations. Additionally, many hot melt adhesives are non-toxic and environmentally friendly, aligning with sustainable manufacturing practices.

Tip: Always ensure proper equipment maintenance to maximize the lifespan and performance of hot melt coating machines, which can further enhance productivity and consistency in production.

| Industry | Key Benefits | Common Applications | Impact on Efficiency |

|---|---|---|---|

| Packaging | Improved adhesion and seal integrity | Carton sealing, bagging | Reduces production time by 20% |

| Automotive | Enhanced durability and resistance | Sound damping, component assembly | Increases assembly line efficiency by 15% |

| Textiles | Flexible and strong bonding | Fabric lamination, non-woven applications | Cuts finishing time in half |

| Construction | Waterproofing and insulation | Roofing membranes, air barriers | Speeds up project completion by 30% |

| Electronics | Thermal management and stability | Circuit board assembly, potting | Enhances production accuracy |

Maintaining hot melt coating machines is crucial for maximizing their efficiency and ensuring optimal performance in modern manufacturing processes. One of the best practices is to establish a regular maintenance schedule that includes routine inspections and cleaning of the equipment. This involves checking for any wear and tear on components, ensuring that the heating elements are functioning correctly, and regularly replacing any worn-out parts. By addressing these issues proactively, manufacturers can prevent unexpected breakdowns and maintain a consistent production flow.

Another important aspect of maintenance is proper calibration of temperature settings for the hot melt adhesives. Inconsistent temperatures can lead to subpar coating results, affecting product quality. Regular calibration ensures that the machine operates within the required specifications, enhancing adhesive performance and reducing waste. Additionally, keeping detailed records of maintenance activities can help in tracking the performance of the machine over time, allowing for informed decision-making regarding repairs or upgrades. This systematic approach to maintenance not only prolongs the lifespan of the machines but also significantly boosts their overall effectiveness in the manufacturing process.

Hot melt coating technology has become a pivotal aspect of modern manufacturing processes, driven by its versatility and efficiency in various applications. One of the most innovative uses of hot melt coatings is in the pharmaceutical industry, where it enhances drug formulation and delivery systems. The rapid drying capability of hot melt extrusion allows for the continuous production of coated pharmaceutical products, improving their stability and bioavailability. This method not only streamlines production but also aligns with the industry's shift towards sustainable practices.

Additionally, hot melt adhesives are gaining traction across diverse sectors, including electronics and construction. Their strong bonding properties and ease of application make them ideal for assembling electronic components and enhancing the performance of building materials. As manufacturers increasingly adopt eco-friendly solutions, hot melt coatings provide an attractive alternative to traditional solvent-based adhesives, furthering their application in the paints and coatings industry. This trend emphasizes the growing importance of innovation and sustainability in manufacturing, which is crucial for meeting the demands of modern consumers and regulatory standards.