In today's fast-paced printing and manufacturing industry, the demand for high-quality finishes is greater than ever. A UV Coating Machine can elevate the quality of products, leading to increased customer satisfaction. According to John Smith, an industry expert in printing technology, "Investing in a UV Coating Machine is not just a choice; it’s a necessity for growth." His insight highlights the importance of this technology in modern business.

UV coating offers several tangible advantages. It creates a protective layer on printed materials, enhancing their durability. This process also improves the visual appeal, allowing for a vibrant finish that attracts customers. However, some businesses may hesitate due to the initial investment costs. It is crucial to reflect on the long-term benefits versus the upfront expenses. A UV Coating Machine isn't merely a tool; it represents an opportunity to stand out in a competitive market.

While the advantages are clear, there may be challenges in integrating this machine into existing workflows. Training staff can be time-consuming, and some operations may need adjustments. Nonetheless, the potential payoff of using a UV Coating Machine makes it a worthwhile consideration for businesses aiming to innovate and expand their offerings.

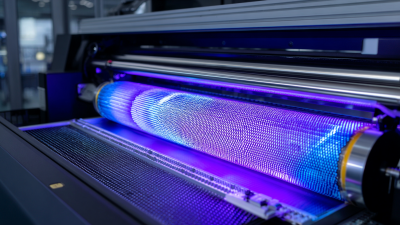

UV coating machines have transformed the way businesses enhance their printed products. These machines utilize ultraviolet light to cure or dry coatings instantly. This advanced technology allows for a durable and high-gloss finish, enhancing the visual appeal of graphic designs. The process involves applying a liquid coating that hardens upon exposure to UV light. It’s efficient and minimizes drying times, which is critical for high-demand environments.

The versatility of UV coating machines is notable. They can handle various substrates, including paper, plastic, and metal. This flexibility allows businesses to cater to different client needs. However, operating these machines may require specialized training. It can take time to master the settings for different coatings and materials. Additionally, maintenance and setup can be challenging, especially for smaller operations. Not all staff may be comfortable with this sophisticated technology right away. But once mastered, the efficiency can significantly boost productivity.

UV coating offers significant advantages for product durability in various industries. The process involves applying a liquid coating that cures quickly under ultraviolet light, resulting in a hard finish. According to a recent industry report, products with UV coatings show an increase in scratch resistance by up to 90%. This means your products not only look better but last longer in challenging environments.

Additionally, UV coatings provide protection against moisture and chemicals. Many manufacturers report a decrease in product degradation due to environmental factors. In fact, products coated with UV technology can last up to three times longer than those without. This durability reduces replacement costs and enhances customer satisfaction.

Tip: Regular maintenance of the UV coating machine can significantly improve efficiency and output quality.

However, the initial setup costs can be high. Companies must weigh the upfront investment against long-term benefits. Understand that not all substrates respond equally to UV coatings. Proper testing is crucial.

Tip: Always conduct small-scale tests before full production to avoid costly mistakes. Evaluate how different materials react to UV coatings for the best results.

| Benefit | Description |

|---|---|

| Enhanced Durability | UV coating provides a hard, protective layer that significantly extends the life of printed materials. |

| Improved Aesthetics | Creates a vivid finish that enhances colors and provides a professional look to products. |

| Fast Drying Time | UV coating cures almost instantly when exposed to UV light, speeding up production times. |

| Resistance to Scratches | The hard surface created by UV coating is highly resistant to scratches and abrasions. |

| Environmental Benefits | UV coatings are often more environmentally friendly compared to traditional coatings, emitting fewer VOCs (volatile organic compounds). |

| Versatility | Can be applied to various substrates, including paper, plastics, metals, and wood. |

| Cost-Effectiveness | Reduces the need for additional protective steps, thus saving costs on materials and production time. |

| Customization Options | Various finishes and textures can be achieved, allowing for tailored solutions for specific products. |

| Increased Profit Margins | Higher quality and more durable products can justify price increases, boosting profits. |

| Enhanced Print Quality | UV coating can enhance the sharpness and clarity of printed graphics and text. |

UV coating machines significantly enhance production efficiency in various industries. These machines offer rapid curing of coatings, which boosts output speed. This fast process allows businesses to complete jobs quicker and take on more projects. Consequently, production timelines shrink, leading to satisfied customers and repeat orders.

Additionally, UV coating improves product durability and appearance. The coatings provide a strong protective layer against scratches and UV damage. However, companies need to ensure their employees are trained properly. Misuse or improper settings can lead to less than optimal results. Regular maintenance is also crucial to keep the machine running smoothly.

While the benefits are clear, adopting UV coating technology comes with challenges. Some businesses may struggle with the initial investment. Others might face learning curves in operating new equipment. These obstacles require thoughtful consideration before integrating UV coating into production processes.

Cost-effectiveness is a significant reason many businesses invest in UV coating solutions. According to a report by the Printing Industries of America, UV coatings can reduce the need for multiple print passes. This leads to lower ink consumption and faster production times. Businesses can save up to 20% in material costs by adopting these technologies.

The initial investment may seem high. However, the longevity and durability of UV coatings offset these costs. UV coatings are resistant to scratches and fading. This means fewer reprints or replacements over time. A study from the National Association of Printing Ink Manufacturers indicated that UV-coated products have a lifespan increase of up to 50%. This translates to substantial savings in the long run.

While many companies focus on upfront expenses, they often overlook hidden costs. Maintenance and waste can add up quickly in traditional printing methods. Businesses must weigh these factors against UV coating technology. The transition requires careful planning but can yield remarkable financial benefits. The journey has its challenges, yet many find the rewards worth the effort.

UV coating technology offers significant environmental advantages. This innovation reduces VOC emissions, which harm air quality. Reports indicate that UV coatings emit up to 80% fewer VOCs than traditional solvent-based options. This means a cleaner workplace and a lower carbon footprint for businesses. Additionally, UV coatings use energy-efficient curing processes that minimize electricity consumption.

Investing in UV coating machines can also align with sustainable practices. Many UV coatings are made from renewable resources, further enhancing their eco-friendliness. The durability and longevity of these coatings mean they require less frequent reapplications. This conserves resources and reduces material waste over time. Research suggests businesses can decrease their waste by up to 50% by switching to UV coatings.

Tip: Consider conducting an environmental impact assessment before making the switch. This can help clarify the long-term benefits. Another useful tip is to train staff on UV technology. Providing education ensures proper usage and maximizes efficiency. While the transition to UV coatings can be strong, challenges like initial costs and training exist. Reflecting on these factors is crucial for smoother implementation.