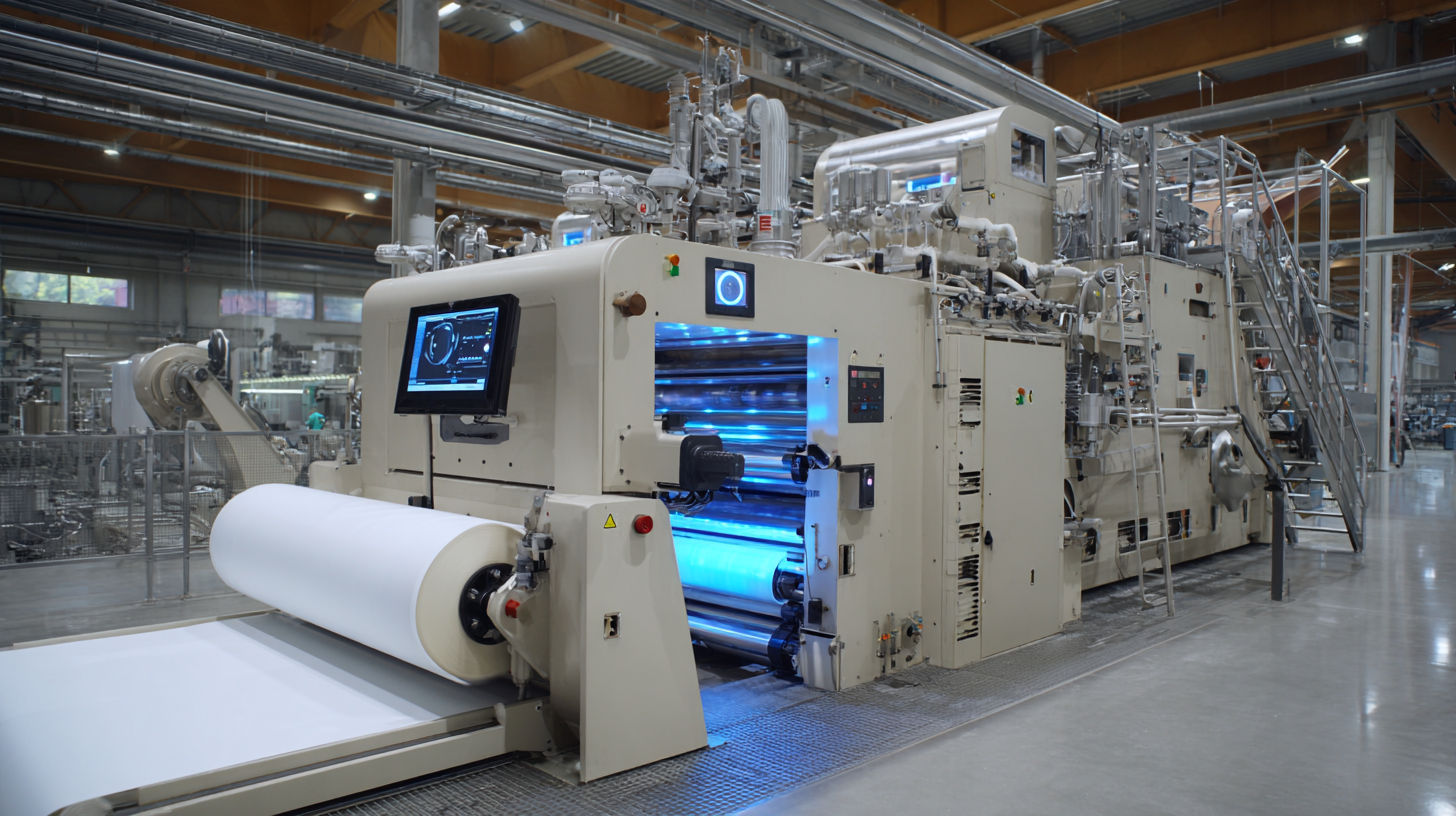

In today's fast-paced manufacturing landscape, the importance of efficiency and quality cannot be overstated, especially in the realm of surface treatments and finishes. One key innovation that has transformed production processes globally is the Heated Coating Machine. This state-of-the-art technology not only enhances the application of coatings but also improves adhesion, durability, and overall aesthetic appeal. As businesses strive to compete in both domestic and international markets, incorporating a Heated Coating Machine into their operations has become essential. This blog will explore seven compelling reasons why investing in a Heated Coating Machine is a game-changer for manufacturers aiming to elevate their products and streamline their production workflows. From improved operational efficiency to superior product quality, the benefits are substantial and can significantly impact a business's bottom line.

Investing in advanced heated coating technology plays a crucial role in driving business growth, particularly in industries where product durability and performance are paramount. Heated coating machines offer a significant advantage in enhancing the quality and lifespan of coatings by ensuring optimal application conditions. This efficiency not only enhances product reliability but also reduces the frequency of maintenance and replacements, leading to cost savings in the long run.

Additionally, as markets for products like wind turbine protection and semiconductor manufacturing continue to expand, the demand for high-performance coatings becomes increasingly vital. The projected growth in the protective coating market indicates a promising future for businesses that leverage cutting-edge technology. By adopting advanced heated coating solutions, companies can stay ahead of industry trends, meet regulatory standards, and exceed customer expectations, ultimately solidifying their competitive edge in a rapidly evolving marketplace.

Heated coating machines have become a pivotal asset in various manufacturing sectors, enhancing efficiency and driving productivity. By applying heat during the coating process, these machines ensure that materials adhere better and cures faster, significantly reducing production time. This not only accelerates the overall manufacturing cycle but also minimizes downtime, allowing businesses to maintain a steady output and meet market demands promptly.

Moreover, the precision of heated coating machines plays a crucial role in improving product quality. The controlled heating environment helps achieve uniform coating thickness and consistency, which directly impacts the durability and performance of the final product. With reduced likelihood of defects and imperfections, companies can enjoy higher customer satisfaction rates and fewer returns, ultimately leading to increased profitability. As competition in the market intensifies, investing in a heated coating machine is not just an enhancement—it's becoming essential for businesses aiming to gain a competitive edge.

When considering the integration of heated coating machines into your business operations, the focus on cost-effectiveness cannot be overstated. According to a recent industry report by TechNavio, utilizing advanced heated coating solutions can lead to a reduction in energy costs by up to 30%. This significant savings can be attributed to the improved efficiency and faster curing times provided by modern heated coating technologies. Consequently, companies can optimize their production cycles, minimize wastage, and ultimately increase their profit margins.

Furthermore, the longevity of heated coatings contributes to substantial long-term savings. A study published in the Journal of Coatings Technology revealed that projects utilizing high-quality heated coatings experienced a 25% increase in durability and lifespan compared to traditional coating methods. This translates into fewer maintenance visits and lower replacement costs over time, allowing businesses to allocate their resources more efficiently. Investing in the best heated coating solutions not only enhances product quality but also drives financial sustainability, making it a smart choice for businesses looking to maintain a competitive edge in their respective markets.

In today's competitive landscape, staying ahead means not just keeping pace but pushing the boundaries of innovation and quality. A heated coating machine can provide a significant competitive advantage, particularly when it enables businesses to deliver superior coating quality. This is crucial as industries evolve and the demand for higher standards intensifies. For example, advancements in internal coatings for products like aluminum cans are setting new benchmarks for safety and regulatory compliance, illustrating the need for cutting-edge machinery that can support such innovations.

As markets shift, especially in burgeoning sectors like the detailing industry, the right equipment can make all the difference. With the US carwash and auto detailing industry projected to grow substantially by 2025, companies must leverage every tool at their disposal to ensure they meet customer expectations and regulatory demands. A best-in-class heated coating machine not only improves operational efficiency but also enhances product quality, empowering businesses to stand out in a crowded marketplace. In this way, investing in advanced coating technology is not merely an option; it's an essential step towards long-term success.

In today’s fast-paced manufacturing environment, adapting to industry trends is crucial for staying competitive. Innovative coating machines, particularly heated coating machines, not only improve product quality but also enhance operational efficiency. By incorporating these advanced technologies, businesses can streamline their processes, reduce waste, and meet evolving customer demands. These machines are designed to apply coatings uniformly and quickly, ensuring that products are not just visually appealing but also durable and long-lasting, which is essential in a market that places a premium on quality.

Furthermore, as industries shift towards more sustainable practices, investing in heated coating machines can future-proof your business. These machines often utilize environmentally friendly coatings and energy-efficient processes that minimize environmental impact. By aligning with green initiatives, businesses appeal to eco-conscious consumers while complying with regulations. Ultimately, the right coating machine is not merely an asset; it’s a vital component that prepares companies to navigate the complexities of future market trends and consumer expectations effectively.