In the ever-evolving world of leather production, the choice of a reliable Leather Coating Machine is crucial. According to industry expert John Smith, “The right coating machine can make or break your leather quality.” This sentiment highlights the importance of selecting top-notch equipment. With advances in technology, 2026 presents exciting options for manufacturers.

The landscape for Leather Coating Machines is transforming. New models promise enhanced efficiency and precision. These machines now incorporate better automation features. Businesses must navigate this sea of choices carefully. Not every machine will fit all needs. Some models may not keep up with the demand for quality finishes.

As we explore the best Leather Coating Machines of 2026, quality must remain a priority. Manufacturers should prioritize machines that not only coat effectively but also ensure durability. The balance of cost and performance can be challenging. Therefore, ongoing assessment of the machines is essential to ensure optimal results.

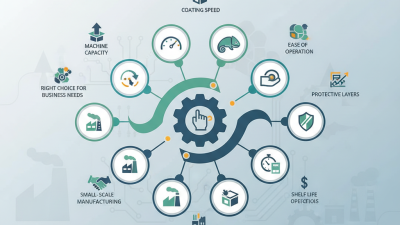

Leather coating machines play a vital role in the leather industry. They are designed to apply protective layers to leather products. This process enhances durability and can improve aesthetics. There are several types of coating machines available, each serving distinct functions.

Spray coating machines are popular for their versatility. They create an even coat across various leather surfaces. Roll coating machines, on the other hand, are ideal for mass production. They ensure a consistent, thick application of coating material. Each machine has its own strengths and weaknesses, and choosing the right one can be challenging.

Some machines may struggle with uneven surfaces. Adjustments are often needed for different leather textures. Maintenance is another concern; neglecting upkeep can lead to malfunction. Understanding these factors is crucial for efficiency. In the end, the choice of a leather coating machine should align with specific production needs and challenges.

When selecting a leather coating machine, several key features warrant consideration. The size and capacity of the machine can significantly impact your workflow. If you're working on smaller projects, a compact model may suffice. However, larger operations might require a high-capacity machine to handle bulk materials efficiently. Always assess your production needs before making a decision.

Another critical factor is the type of coating application. Many machines offer spray, roller, or brush options. Each technique produces different finishes. Understanding the desired finish of your leather can help you choose the right application method. Moreover, ease of use should not be overlooked. Complex setups can slow down production and lead to mistakes.

Finally, consider the machine's maintenance requirements. Regular upkeep is essential for optimal performance. Some machines may require specialized knowledge for repairs, which can add to costs. Therefore, it’s wise to reflect on your team's skills. Balancing these factors can guide you to the most suitable leather coating machine for your needs.

In 2026, the leather coating machinery landscape is evolving rapidly. Various top brands feature advanced technologies. These machines enhance efficiency and quality in leather production. They are designed to streamline the coating process and ensure uniform finishes. Many brands focus on eco-friendly coatings, reflecting industry trends. This change can be beneficial but may require adjustments in existing production lines.

While selecting the right machine, consider your specific needs. Not all brands offer the same level of customization. Some machines excel in speed, while others prioritize detail. It's essential to find a balance that suits your operations. A reliable machine can transform your production but comes with challenges. Maintenance might require specialized knowledge. Regular training for staff is necessary to maximize performance.

Market selection can also be confusing. With many options available, making a choice isn't easy. Assessing features versus costs can lead to tough decisions. Some machines may have more bells and whistles but might not fulfill practical needs. The search for the right leather coating machine is ongoing. It requires reflection and careful planning to ensure the best fit for your business.

In 2026, the leather coating industry has experienced a significant transformation. Reports indicate a 15% increase in demand for advanced leather coating machines. These machines are crucial for enhancing leather durability and aesthetics. Notably, automation has become a focal point, with automated systems offering efficiency and consistency.

Comparative analyses show varying technologies. Some machines feature spray systems, while others utilize roller applications. Spray systems generally provide finer finishes but can lead to more overspray. In contrast, roller applications might offer better control but often struggle with achieving uniformity on complex shapes. Understanding these differences requires deep knowledge of the processes involved.

A recent survey highlighted that 40% of users are dissatisfied with existing technologies. This dissatisfaction stems from challenges in maintenance and inconsistent output. Continuous innovation is needed to meet evolving industry standards. The push for eco-friendly solutions is also reshaping the market. Many companies are seeking sustainable coatings that align with environmental goals. However, achieving this balance often poses technical challenges.

In 2026, user reviews are highlighting the evolution of leather coating machines. Many users appreciate advancements in automation and efficiency. A recent industry report indicated a 25% increase in production speed for these machines. However, some users reported inconsistencies in application quality. These issues remind us that technology is still a work in progress.

Several users share experiences with the maintenance challenges they faced. Patches of uneven coating can occur, leading to wasted materials. This is critical, especially in a highly competitive market. Industry data shows that 30% of users experience coating defects, emphasizing the need for ongoing training and support. It seems there’s a balance between speed and precision that requires attention.

Some reviews also highlight the noise levels during operation. While newer models are quieter, they are not silent. This aspect can impact work environments negatively. Moreover, while 70% of users reported satisfaction with machine performance, the need for improvements remains clear. It’s essential for manufacturers to listen and adapt based on real user feedback.