In the rapidly evolving field of battery technology, the performance of lithium batteries is significantly influenced by the quality of the manufacturing process. As the demand for more efficient energy storage solutions continues to rise, having the right equipment is paramount. According to Dr. Emily Carter, a leading expert in battery manufacturing technology, “Investing in a high-performance Lithium Battery Coating Machine is critical to ensure optimal battery efficiency and longevity.” With this insight in mind, manufacturers are increasingly seeking advanced coating solutions to enhance their production capabilities.

In this article, we will explore the best 10 Lithium Battery Coating Machines that are revolutionizing the industry. These machines not only improve the coating uniformity and adhesion but also enhance energy density, resulting in superior battery performance. As the lithium-ion battery market grows, understanding the key features and benefits of these machines becomes essential for manufacturers looking to stay competitive and meet the evolving demands of consumers. Together, let’s delve into the top choices available and their impact on the future of battery technology.

As the demand for lithium batteries continues to rise, driven by electric vehicles (EVs) and renewable energy solutions, the coating technology for these batteries is evolving rapidly. By 2025, the market for lithium battery coating machinery is projected to grow significantly, with recent industry analyses indicating a CAGR of over 15% from 2023 to 2028. This surge in growth is largely fueled by advancements in materials and automation technologies that enhance the precision and efficiency of the coating process.

One of the most significant trends in lithium battery coating technology is the integration of advanced robotics and AI-driven solutions. These innovations allow for higher consistency in coatings, thereby improving battery performance and lifespan. Reports from the International Battery Association show that optimized coating thickness can increase battery efficiency by up to 12%, directly impacting energy density and charge cycles. Furthermore, eco-friendly coating materials are gaining traction, with companies investing in research to develop biodegradable alternatives that minimize environmental impact while maintaining high performance levels. As we move into 2025, these trends will not only redefine manufacturing processes but also set new standards for sustainability in the lithium battery sector.

When selecting a lithium battery coating machine, it's crucial to consider key features that ensure superior performance and efficiency. One of the primary features to look for is the precision coating technology, which allows for uniform application of coatings to the electrodes. According to a recent industry report by Grand View Research, the global lithium-ion battery market is expected to reach $148.7 billion by 2025, highlighting the importance of investing in advanced machinery to meet increasing production demands.

Another vital aspect is the machine’s scalability. As production volumes rise, the ability to easily scale operations without compromising quality becomes essential. Machines equipped with adjustable coating speeds and versatile configurations can significantly enhance productivity. Additionally, energy efficiency is increasingly important, as production processes are scrutinized for their environmental impact. A report by the International Energy Agency noted that energy-efficient machines can reduce operational costs by up to 30%.

Tip: When evaluating options, ensure that the machine provides real-time monitoring capabilities, allowing for immediate adjustments during the coating process. This feature not only boosts productivity but also enhances the consistency of the coating thickness, ultimately leading to higher battery performance and longevity.

In the rapidly evolving landscape of lithium battery production, the choice of coating machines plays a crucial role in enhancing performance metrics. A recent report by MarketsandMarkets highlights that the global lithium-ion battery market is expected to grow from $41.2 billion in 2021 to $116.6 billion by 2026, driven by the demand for electric vehicles and renewable energy storage. This growth underlines the importance of selecting high-efficiency coating machines from leading brands, as even marginal improvements in coating quality can drastically enhance battery longevity and energy density.

Analyze competitive models from prominent manufacturers such as Coating Systems Inc. and MKE, which have been proven to optimize the uniformity of electrode coatings. According to a study published in the Journal of Power Sources, enhancing coating uniformity can lead to a 30% increase in battery capacity. Additionally, brands that employ advanced automation and AI-driven processes typically experience a 15-20% reduction in production costs. Understanding the specifications and performance metrics of these machines is essential for manufacturers seeking to remain competitive in the lithium battery market.

In the rapidly evolving field of lithium battery production, sustainability and efficiency have emerged as key factors shaping coating processes. The demand for environmentally friendly solutions has led manufacturers to adopt advanced coating technologies that minimize waste and reduce the carbon footprint. Innovations such as water-based coatings and solvent-free processes are becoming increasingly popular, ensuring that lithium battery coating not only meets performance standards but also adheres to eco-friendly practices.

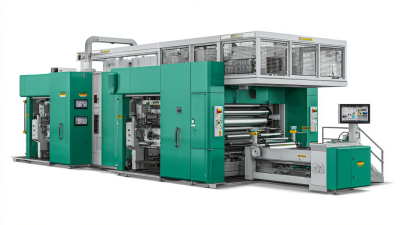

Efficiency is another critical component in enhancing the overall productivity of lithium battery manufacturing. Modern coating machines are designed with high precision and automation features that streamline operations. These machines optimize the use of materials and energy, resulting in significant cost savings and reduced lead times. By focusing on sustainable and efficient lithium battery coating processes, manufacturers can better position themselves in a competitive market while contributing to a greener future in energy storage solutions.

This bar chart illustrates the coating efficiency percentage of the top 10 lithium battery coating machines. Each machine demonstrates varying levels of efficiency, which is critical for sustainable and high-performance battery production.

The rapid evolution of lithium battery technology is driving innovation in coating equipment, with an emphasis on enhancing performance and efficiency. Recent industry reports indicate that the global lithium-ion battery market is projected to reach $129 billion by 2027, growing at a CAGR of 18.0% from 2020. This surge has spurred manufacturers to invest in advanced coating solutions, focusing on superior uniformity and adhesion in electrode production. Advanced machines equipped with real-time monitoring systems are enabling precise control over the coating process, which is crucial for the consistency and quality of battery performance.

Future innovations in lithium battery coating equipment will likely integrate cutting-edge materials and nanotechnology to further improve efficiency. For instance, the development of new polymer and ceramic coatings can enhance thermal stability and cycle life, which are critical for high-performance applications. According to a study by the International Energy Agency, improved electrode coatings could lead to a reduction in battery costs by up to 30%, while also significantly boosting energy density. Manufacturers that adopt these innovative coating technologies will be well-positioned to meet the growing demand for more efficient and durable lithium batteries across various industries, including electric vehicles and renewable energy storage.