In today's fast-paced manufacturing landscape, efficiency is crucial. Small coating machines have become essential tools for various industries. They are designed to optimize production processes while maintaining quality. These machines offer versatility for multiple applications, making them popular among manufacturers.

Choosing the right small coating machine can be challenging. Different models serve distinct purposes. Some machines excel in speed, while others focus on precision. It is important to evaluate your specific needs and production goals. Investing in inefficient equipment may lead to delays and increased costs.

Understanding the features of small coating machines is equally important. Look for ones that offer consistent performance. Some machines may lack certain functionalities or require frequent maintenance. Such aspects can hinder productivity. A thoughtful selection process can minimize these risks, ultimately improving your manufacturing efficiency.

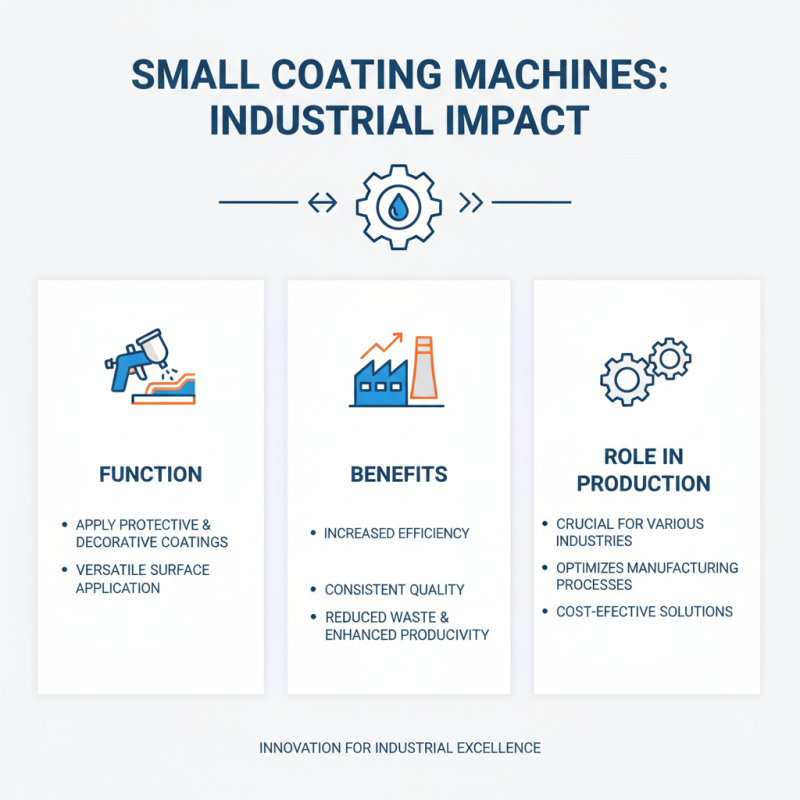

Small coating machines play a crucial role in industrial production. These machines are designed to apply protective or decorative coatings on various surfaces. They help increase efficiency and ensure consistent quality. In a manufacturing environment, the right coating machine can significantly reduce waste and enhance productivity.

Workers often face challenges when using these machines. Adjusting settings can be complex. Some machines require extensive training, making the learning curve steep. Moreover, maintenance is essential to avoid breakdowns and ensure smooth operations. Regular checks can prevent unexpected downtimes, but they add to operational pressures.

The versatility of small coating machines makes them appealing. They can handle different materials, from plastics to metals. Different applications may require unique coatings and techniques. It’s imperative for manufacturers to evaluate their needs carefully. Sometimes, the chosen machine may not perform as expected. This can lead to inefficiencies that impact production schedules. Finding the right balance between speed and precision is often a challenge in the manufacturing process.

When exploring small coating machines for efficient production, several key features stand out. Firstly, consider the machine's capacity. A report from the Coating Equipment Market indicates that machines with a higher throughput volume can enhance productivity by up to 25%. This metric is crucial for small businesses aiming to scale operations without major investments.

Precision in application is another vital feature. Machines that offer adjustable settings allow for more control over coating thickness. According to industry studies, precise coatings reduce material waste by about 15%. This is an essential factor for businesses looking to improve profitability while minimizing excess.

Tip: Always evaluate the machine's maintenance requirements. A machine that’s easy to clean can save time and prevent downtime.

Efficiency also relies on energy consumption. Energy-efficient machines can cut operational costs significantly. Some reports suggest that using advanced technology can reduce energy usage by up to 30% compared to traditional models.

Tip: Look for models that provide energy-saving modes. These can be beneficial during off-peak production times.

Lastly, user-friendly interfaces enhance the overall operational experience. Operators are more likely to make fewer errors when they can navigate a straightforward setup. This can make a difference in daily production output.

When choosing a small coating machine, it's essential to assess their capabilities. Different models offer varying features. Some machines excel in speed, while others focus on precision. Analyzing each option can help you find the best fit for your needs.

It's worth noting that not all small coating machines deliver consistent results. Some users report issues like uneven coating thickness. Others mention that certain models require frequent calibration. While some machines are user-friendly, others can be complicated to operate. It’s crucial to read user reviews and feedback carefully. This can provide insight into potential drawbacks.

Investing in a small coating machine means weighing benefits against cost. Some options might be more economical upfront but lack durability. Others could show high initial costs while offering better long-term value. The right choice depends on your production goals and the materials you intend to work with. Balancing performance and practicality is key.

Operating small coating machines efficiently requires attention to both technique and maintenance. Regular monitoring is essential. A recent industry report highlighted that lack of routine checks can lead to a 30% increase in downtime. This not only affects output but also impacts overall production costs. Scheduling inspections ensures that any wear or malfunction can be addressed promptly.

Employee training is another critical aspect. Workers should understand both the machine’s features and the coating process. An effective training program can boost efficiency by 25%, according to research from a manufacturing association. Visual aids and hands-on practice often enhance understanding. However, many facilities underutilize training resources, leading to mistakes that could have been avoided.

Controlling the environment in which coating machines operate is vital. Temperature and humidity levels can significantly impact coating quality. Ideal conditions often vary, but many manufacturers recommend a stable environment. While achieving this stability may seem simple, it can be overlooked. Poor environmental control can lead to defects. A proactive approach here is often lacking. Regularly reviewing and adjusting conditions is beneficial for maximizing machine performance.

Coating machines play a crucial role in various industries. To ensure their longevity and performance, regular maintenance is essential. Start by inspecting the components frequently. Clean the surfaces to remove dust and debris. Neglecting this could lead to decreased efficiency or even machine failure.

Pay attention to the lubrication of moving parts. This helps in reducing friction and wear. Use the recommended lubricants specified in the user manual. It’s easy to overlook this step, but it can prevent costly repairs. Also, check belts and hoses for signs of wear. Replacing them before they break can save time.

User training is vital for optimal performance. Operators should fully understand the machine’s functions. Misuse can lead to malfunctions that are easily avoidable. Document any issues that arise during operations. This record can provide insights for future improvements. Keep an eye on production output. Regular assessment can ensure the machine runs efficiently. Maintenance may seem tedious, but it's a wise investment for productivity.