In the evolving landscape of manufacturing, the Transfer Coating Machine stands out as a pivotal tool. According to a recent market report, the global transfer coating market is expected to grow at a CAGR of 5.1% from 2021 to 2026. This growth reflects the increasing importance of high-quality coatings in sectors such as automotive, electronics, and textiles.

Choosing the best Transfer Coating Machine can significantly impact production efficiency and product quality. For example, precision in coating thickness can lead to better adhesion and durability. However, not all machines are created equal. Users must consider factors like speed, ease of operation, and maintenance cost.

Moreover, emerging trends indicate the rise of eco-friendly materials in coating processes. Adopting sustainable practices can enhance brand reputation but may require a shift in existing machinery. As industries evolve, the demand for optimized solutions will become crucial. Companies must reflect on their current capabilities and align them with future needs.

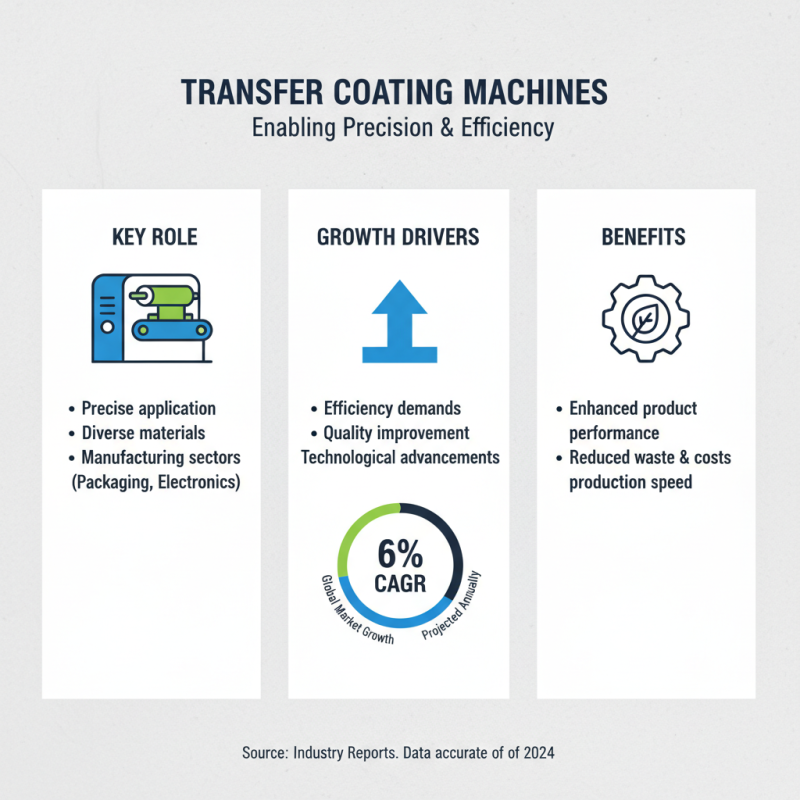

Transfer coating machines play a crucial role in various manufacturing sectors. They allow for precise application of coatings on diverse materials. These machines have gained attention due to increasing demands for efficiency and quality. According to industry reports, the global market for coating machinery is projected to grow by 6% annually.

Understanding transfer coating machines requires knowledge of their components. Key parts include the transfer rollers, coating applicators, and curing systems. Each component affects the final product's quality. For instance, slight variances in roller pressure can lead to significant differences in coating thickness. Manufacturers must be aware that adjusting these settings requires meticulous calibration.

Data suggests that improper use can lead to inefficiencies and excess waste. Reports indicate that about 12% of operations suffer from such issues. The industry still faces challenges regarding cleanup and maintenance. Operators should prioritize regular training to mitigate these problems. Observing basic operational parameters can lead to more efficient production lines.

When considering a transfer coating machine, several key features stand out. Precision is paramount. Research indicates that machines with an accuracy rate above 95% produce better results. Coating thickness is another critical aspect. Data suggests that a uniform thickness of 10-20 microns is optimal for most applications. Variability beyond this range can lead to defects.

Ease of use can impact productivity significantly. Machines featuring user-friendly interfaces reduce training time. Industry reports show that companies that prioritize operator training increase output by 25%. Maintenance requirements matter too. Machines that need frequent repairs can slow down operations. Regular maintenance should not exceed 5% of the total operational time to stay efficient.

Energy efficiency has become increasingly important. Machines with lower energy consumption help companies align with sustainability goals. Reports indicate that energy-efficient systems can cut costs by 20% annually. Making thoughtful choices in this area can also improve overall performance. However, achieving the perfect balance between efficiency and output sometimes requires trial and error.

| Model | Max Speed (m/min) | Coating Width (mm) | Power Consumption (kW) | Weight (kg) | Special Features |

|---|---|---|---|---|---|

| Model A | 50 | 1200 | 15 | 300 | Auto Temperature Control |

| Model B | 60 | 1400 | 12 | 350 | Multi-layer Coating |

| Model C | 45 | 1000 | 10 | 280 | Compact Design |

| Model D | 55 | 1300 | 14 | 320 | User-friendly Interface |

| Model E | 65 | 1500 | 16 | 400 | Energy Efficient |

In 2026, the transfer coating machine market is becoming increasingly competitive. Various brands are vying for consumer attention. According to an industry report, the demand for high-efficiency machines is on the rise. Over 70% of manufacturers prefer automated processes to enhance productivity. The leading models are those that marry speed with precision, ensuring high-quality output.

Specific features stand out in popular models this year. Machines with advanced temperature controls significantly reduce defects in coating applications. Furthermore, user-friendly interfaces are essential. Operators value easy-to-navigate settings, especially for intricate designs. A survey highlighted that 68% of users prioritize maintenance simplicity in their purchasing decisions.

However, not every machine delivers as promised. Some models struggle with consistency, creating a gap in expected performance. This inconsistency can lead to production delays and increased costs. In a fast-paced market, efficiency is paramount. Choosing the right machine requires careful consideration of both features and reliability. As technology evolves, so too must the evaluation methods employed by buyers.

When choosing between manual and automated transfer coating machines, understanding their differences is crucial. Manual machines offer flexibility. Operators can adjust the process based on specific needs. This can lead to unique applications. However, human error is a concern. An unsteady hand may result in inconsistent coatings. Operators may become fatigued, affecting performance over time.

On the other hand, automated machines excel in speed and precision. They can produce consistent results quickly. Large production runs benefit from this efficiency. However, these machines can be costly. Initial investment and maintenance are significant. Furthermore, they may not adapt easily to sudden changes in requirements. If a new material needs coating, operators may need to reprogram or recalibrate.

Evaluating your production needs is essential. A balance between cost-efficiency and quality is vital. While automated systems shine in high-volume scenarios, manual machines still have their place in niche applications. Understanding these trade-offs can guide you to the best choice for your organization.

When considering a transfer coating machine, budget is often a primary concern. Industry reports show that costs can vary widely based on functionality and specifications. A good machine can range from $5,000 to $50,000. This large price gap raises questions about cost-effectiveness. It’s essential to evaluate what features you really need. Spending more does not always equal better performance.

Tips: Assess your production volume. High-demand operations may benefit from advanced machines. Yet, for low-volume needs, basic models could suffice. Research lifecycle costs, including maintenance and consumables. Each machine has different needs. A machine with lower upfront costs may lead to higher long-term expenses.

Be cautious about underestimating your needs. Many customers initially opt for cheaper options. Later, they face performance issues. A machine that does not meet your requirements can lead to delays and increased operational costs. Balance initial price and potential performance. Invest wisely; it can save money down the road.