Selecting the right Transfer Coating Machine is crucial for businesses looking to enhance their production capabilities and improve product quality in 2025. As technology continues to evolve, the variety and sophistication of transfer coating machines have expanded, making it vital for companies to understand their options thoroughly. Whether you are in the textile, automotive, or packaging industry, choosing the correct machine can significantly impact your operational efficiency and ultimately your bottom line.

In this fast-paced market, various factors must be considered when selecting a Transfer Coating Machine, including the machine's capacity, coating type, compatibility with existing systems, and cost-effectiveness. Additionally, businesses should assess future needs and potential scalability, ensuring that the chosen machine can adapt to evolving production demands. As sustainability becomes a priority, the machine's environmental impact and energy efficiency also warrant attention.

By understanding the key features and industry trends, business owners can confidently make informed decisions when choosing the best Transfer Coating Machine for their needs. This guide aims to illuminate the essential criteria and trends that will shape your purchasing decision in 2025, ensuring your investment supports your business objectives and positions you for success in a competitive landscape.

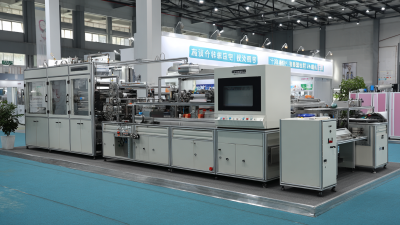

Transfer coating machines play a pivotal role in various industries, offering a versatile solution for applying coatings to a multitude of surfaces. These machines use heat and pressure to transfer inks or coatings from a carrier material onto substrates, allowing for intricate designs and durable finishes. Understanding the specific applications of transfer coating machines is crucial for selecting the right machine for your business needs. Industries such as textiles, packaging, and electronics benefit greatly from the precise and efficient coating capabilities that these machines provide.

When choosing a transfer coating machine, it is vital to consider the materials you will be working with. Different machines are designed to handle various substrates, including textiles, metals, and plastics. Additionally, the scale of your operations—whether you are a small business or a large manufacturer—will influence your choice. For instance, high-speed transfer coating machines may be ideal for large production runs, while smaller, more customizable machines can cater to niche applications and smaller quantities.

By comprehensively understanding the capabilities and applications of different transfer coating machines, businesses can make informed decisions that enhance efficiency and product quality in their operations.

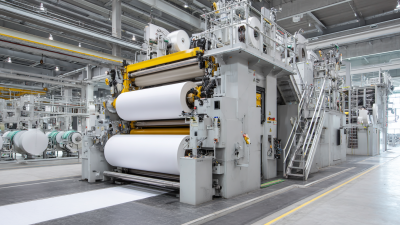

When selecting the best transfer coating machine for your business in 2025, it's essential to consider several key features that can enhance efficiency and output quality. Firstly, the machine's speed and efficiency are crucial. A model that offers adjustable speed settings allows for flexibility in production, catering to different project requirements without compromising quality. Look for machines equipped with advanced technology that ensures uniform coating application, which can significantly reduce material waste and improve overall production costs.

Additionally, the ease of operation and maintenance should not be overlooked. A user-friendly interface with intuitive controls can minimize the learning curve for new operators and lead to less downtime. Moreover, machines with self-cleaning capabilities or easy disassembly for maintenance can save valuable time and resources in the long run. Finally, consider the versatility of the machine. Models that can accommodate various materials and coating types can provide your business with the flexibility to adapt to changing market demands and expand your production capabilities.

When considering the purchase of a transfer coating machine in 2025, it's crucial to thoroughly assess your business needs and budget. The selection process begins with identifying the specific applications your machine will handle. For example, recent industry reports indicate that the demand for durable and high-quality finishes is driving companies to explore advanced coating technologies, expected to grow at a CAGR of 5.2% from 2023 to 2028. Understanding the output requirements and the types of substrates you'll be working with will help narrow down the options.

Budget considerations are just as essential. A comprehensive study by the Coating Equipment Manufacturers Association (CEMA) reveals that businesses should allocate approximately 15-30% of their total equipment budget specifically for coating machinery. This allocation not only covers the initial purchase cost but also maintenance, training, and potential upgrades. Moreover, weighing factors such as energy efficiency and operational costs against the capabilities of the machine can lead to long-term savings and improved operational efficiency. Ensuring that your investment aligns with both current and future production goals will pave the way for sustained growth in your coating operations.

When selecting the best transfer coating machine for your business in 2025, it’s essential to consider the leading brands and models that are setting industry standards. According to the latest report from MarketsandMarkets, the global market for transfer coating machines is projected to grow at a CAGR of 5.8% from 2024 to 2029, driven by advancements in automation and eco-friendly coating technologies. Leading brands like Nordson Corporation, Graco Inc., and ITW are recognized for their innovative approaches and reliable machinery, catering to diverse industry needs from textiles to electronics.

In 2025, models such as Nordson's ProBlue Flex and Graco's Fusion AP are expected to dominate the market due to their efficiency and precision. The ProBlue Flex, for instance, features state-of-the-art technology that reduces material waste by up to 20%, addressing both cost-effectiveness and environmental concerns. Furthermore, ITW's Dynatec model, known for its adaptability in various applications, is favored for its user-friendly interface and streamlined operation. These machines not only enhance productivity but also ensure a high-quality finish, making them ideal choices for businesses looking to invest in durable and efficient coating solutions.

When selecting a transfer coating machine for your business, maintenance and support considerations play a pivotal role in ensuring optimal performance and longevity. Regular maintenance not only minimizes unexpected breakdowns but also extends the lifespan of the equipment. According to a report by the International Society of Coating Inspectors, proper upkeep can reduce operational costs by up to 30% over the machine's lifecycle. This highlights the importance of investing in machinery that comes with reliable maintenance support.

Additionally, the availability of technical support and training resources is crucial. Businesses should consider manufacturers that provide comprehensive training programs for staff, as well as prompt access to technical support. A survey by the Association of Manufacturers of Coating Equipment found that over 60% of companies reported improved productivity after investing in ongoing technical support and maintenance services. This investment in human capital not only enhances the operational efficiency of the transfer coating machines but also improves product quality, meeting the increasing market demands for precision and durability in coatings.