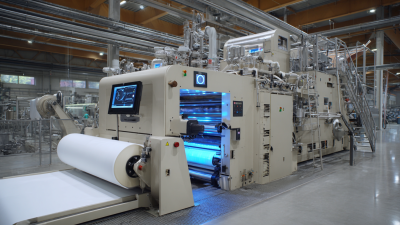

In the ever-evolving landscape of manufacturing, the fiberglass fabric coating machine stands out as a pivotal technology that enhances the durability and functionality of fiberglass products. However, the operations surrounding these machines come with a unique set of challenges that can hinder productivity and efficiency.

From maintaining consistent coating quality to addressing equipment malfunctions and navigating supply chain disruptions, manufacturers must adapt to these complexities to ensure smooth operations. This blog will delve into the top challenges facing fiberglass fabric coating machine operations, providing insights on how to tackle these issues effectively.

By understanding these obstacles, industry professionals can better prepare themselves to maintain the performance and reliability of their fiberglass coating processes, ultimately leading to improved product outcomes and sustained business growth.

In the world of fiberglass fabrication, the efficiency and reliability of coating machines play a pivotal role in ensuring high-quality production. Reliable machinery is crucial not only for maintaining production schedules but also for minimizing defects and enhancing the overall finish of the fiberglass products. When machines fail or operate inconsistently, it can lead to bottlenecks, wasted materials, and increased costs, all of which can undermine a company’s competitiveness.

To maximize the performance of these machines, regular maintenance is essential. Implementing a preventive maintenance schedule can help identify potential issues before they become major problems. Regularly checking the machine's components, such as pumps and spray nozzles, ensures they are functioning correctly and reduces the risk of unexpected downtime.

Additionally, operator training cannot be overlooked. Well-trained staff can effectively troubleshoot minor issues and optimize machine settings for various coating applications. This knowledge not only improves operational efficiency but also enhances product quality. Investing in training and development of operators can yield significant returns in productivity and reliability over time.

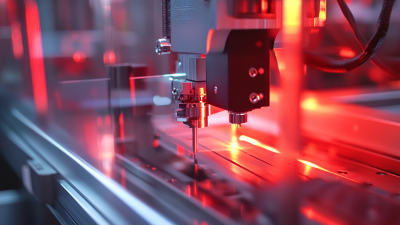

Fiberglass fabric coating machines play a critical role in the manufacturing process, yet they face several operational challenges that can impact productivity and product quality. One of the primary issues is ensuring consistent application of the coating material. Variability in viscosity, temperature, and machine speed can lead to uneven coatings, resulting in compromised performance of the final product. Regular calibration and maintenance of the machine settings are essential to mitigate this issue.

Another challenge is managing waste and ensuring effective cleanup. Excess coating material can accumulate and lead to higher operational costs and environmental concerns. Implementing a streamlined process for material recovery and minimizing overspray can help reduce waste. Additionally, training operators on efficient cleanup routines can directly contribute to minimizing downtime and enhancing operational efficiency.

Finally, operators must be vigilant about monitoring the machine's performance and addressing any mechanical issues promptly. Any delay in identifying problems can lead to costly repairs and production delays. Setting up a regular maintenance schedule and utilizing predictive maintenance technology can significantly improve the reliability and longevity of fiberglass fabric coating machines.

When operating fiberglass fabric coating machines, several common technical issues can arise that may hinder optimal performance. One prevalent challenge is the consistency of the coating application. According to industry data, inconsistent thickness can lead to increased waste and production downtime, impacting the bottom line of manufacturers. To tackle this, regular calibration of the coating system is crucial. Ensuring that measurement tools are functioning accurately can help achieve uniform coating applications.

Another frequent concern is the wear and tear of machinery components due to the abrasive nature of fiberglass materials. Reports indicate that routine maintenance can reduce machine breakdowns by up to 30%. Operators should schedule regular inspections and replace worn parts promptly to maintain efficiency.

Tip: Implement a daily cleaning routine for the coating machine to prevent material buildup, which can affect performance.

Finally, operators often encounter heating issues, which can affect the curing process of fiberglass. Maintaining the heating elements and ensuring consistent temperatures throughout production can significantly enhance product quality.

Tip: Use thermal imaging to detect any hotspots in the machine, allowing for timely adjustments before they escalate into larger problems.

Effective quality control is crucial in fiberglass fabric coating machine operations, where precision and consistency are paramount. One effective strategy is implementing a robust monitoring system that tracks key performance indicators during the coating process. This includes maintaining optimal temperature and viscosity levels, as these factors significantly influence adhesion and finish quality. By utilizing real-time data analytics, operators can quickly identify deviations and take corrective action, ensuring that the end product meets the required specifications.

Another important strategy involves continuous staff training and development. Employees must be well-versed in the intricacies of the coating equipment and the properties of the materials used. Providing regular training sessions on best practices and the latest technological advancements can significantly reduce errors and enhance overall efficiency. Additionally, fostering a culture of quality awareness among employees encourages them to take ownership of their work, leading to a more conscientious approach to the coating process. As a result, the combined efforts of advanced monitoring and skilled personnel contribute greatly to maintaining high standards in fiberglass fabric coating operations.

| Challenges | Impact on Operations | Effective Strategies | Quality Control Measures | Frequency of Assessment |

|---|---|---|---|---|

| Inconsistent Coating Thickness | Leads to product defects and reduced durability | Calibration of coating machinery | Use of ultrasonic thickness gauges | Daily |

| Material Variability | Increased waste and production costs | Supplier quality audits | Incoming material inspections | Weekly |

| Equipment Downtime | Delays in production schedules | Preventive maintenance program | Routine machinery checks | Bi-weekly |

| Environmental Conditions | Affects curing and adhesion properties | Climate control systems | Temperature and humidity monitoring | Continuous |

| Human Error | Compromised product integrity | Regular employee training | Standard operating procedures | Monthly |

As the demand for fiberglass fabric continues to rise in various industries, innovations in coating machines are essential to address the challenges faced in their operations. One significant area of improvement is the development of automated systems that enhance precision and efficiency. These advanced machines utilize AI-driven technologies to optimize the coating process, ensuring a uniform layer while minimizing material waste. This shift not only streamlines production but also grips the attention of manufacturers keen on sustainability.