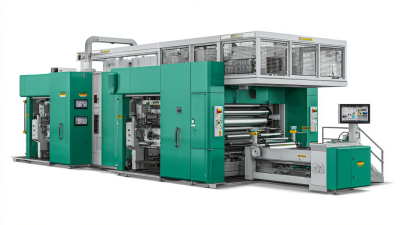

In today's competitive manufacturing landscape, the selection of the right Customizable Coating Machine stands as a critical factor for global buyers aiming to enhance their production efficiency and product quality. The ability to tailor coating machines to specific needs can empower businesses to optimize their processes, meet diverse customer demands, and maintain a competitive edge. However, navigating the myriad options available in the market can be daunting, especially given the varying technologies and functionalities that different machines offer. This blog aims to explore the versatile benefits of Customizable Coating Machines, highlighting how these machines not only support scalable production but also contribute to innovation and sustainability in various industries. By understanding these advantages, buyers can make informed decisions that align with their operational goals and drive long-term success.

Customizable coating machines play a pivotal role in meeting the diverse demands of global markets, particularly as industries strive for efficiency and sustainability. As the market for these machines expands, understanding their significance becomes increasingly important. Buyers must navigate various options that accommodate unique specifications and production needs, ensuring that their selected machines can deliver tailored solutions for their specific applications. This level of customization is crucial in sectors such as automotive, textiles, and electronics, where precision and adaptability can significantly enhance product quality and performance.

The surge in demand for customizable coating machines is further reflected in the expected growth of associated markets, such as graphene coatings and automotive coatings. As industries focus on innovation and sustainability, companies are investing in advanced coating technologies that not only improve product lifespan but also reduce environmental impact. The ability to customize these machines allows manufacturers to stay competitive in a rapidly evolving marketplace, enabling them to address specific challenges and capitalize on emerging opportunities. Ultimately, the strategic selection of customizable coating machines will empower global buyers to optimize their operations and meet the ever-changing demands of their respective sectors.

When global buyers are tasked with selecting customizable coating machines, several key factors significantly influence their decisions. One critical aspect is the machine's adaptability to various product specifications. According to a report by Research and Markets, the global coating equipment market is expected to grow at a CAGR of 6.5% from 2021 to 2028, driven by the rising demand for versatile and efficient coating solutions. Buyers increasingly prioritize machines that can accommodate a diverse range of substrates and coatings, ensuring flexibility in production lines and reducing downtime associated with equipment changes.

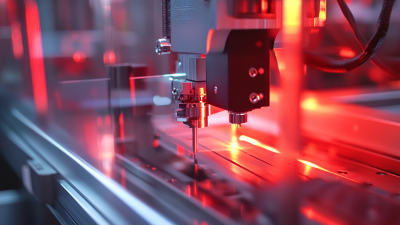

Moreover, the integration of smart technology plays a vital role in the selection process. Buyers are looking for machines equipped with Industry 4.0 features, such as IoT capabilities and advanced data analytics, to enhance process efficiency and monitor real-time performance. A survey by Grand View Research indicated that 50% of manufacturers in the coating industry are actively investing in automation technologies, reflecting a shift towards smarter manufacturing practices. This trend underscores the importance of choosing equipment that not only meets current needs but is also future-proof to adapt to evolving industry standards and customer demands.

When navigating the complex landscape of customizable coating machines, global buyers must carefully evaluate various coating technologies. A comparative analysis highlights the pros and cons of techniques such as electrostatic spray coating, fluidized bed coating, and curtain coating. According to a recent report by Industry Research, the global coating equipment market is projected to reach $29.4 billion by 2025, growing at a CAGR of 4.2%. This growth is driven by advancements in technology and the demand for high-performance coatings across industries.

Electrostatic spray coating, for instance, offers superior transfer efficiency, reducing material waste and improving coverage on complex shapes. However, the upfront investment and operational costs can be significant, making it less attractive for smaller manufacturers. Meanwhile, fluidized bed coating provides uniform thickness and excellent adhesion properties, making it an ideal choice for pharmaceuticals and food products. Nevertheless, it may require extensive cleaning and maintenance, which can add to operational downtime.

A thorough understanding of these technologies is essential for global buyers aiming to optimize their production processes. With a growing emphasis on sustainability, options like water-based and UV-cured coatings are gaining traction, promising lower environmental impact and meeting stringent regulatory requirements. The evolving landscape necessitates continuous research and evaluation to ensure informed decision-making in machine selection.

This chart illustrates the advantages and disadvantages of various coating technologies available to global buyers, highlighting key factors such as cost, efficiency, and versatility.

The customizable coating machine market is poised for considerable growth through 2025, driven by innovative technology and industry demand. As industries increasingly seek tailored solutions for diverse applications, the importance of selecting the right machine becomes critical. Global buyers must navigate numerous factors, such as machine specifications, supplier reliability, and support services when making purchasing decisions.

Tips: When evaluating customizable coating machines, consider the machine's versatility—ensure that it can handle various substrates and coating types. Additionally, look for suppliers that offer comprehensive training and post-purchase support to maximize operational efficiency and reduce downtime.

Market research indicates that by 2025, the global pulp and paper industry will reach a valuation of approximately $351.69 billion, highlighting a burgeoning demand for advanced coating solutions. Staying informed about industry trends can provide insights into which features will become essential for future-proofing machinery.

Tips: Regularly review industry reports and forecasts to stay updated on emerging trends and technologies. Networking with peers and attending industry forums can also provide valuable insights and connections that may assist in making informed purchasing decisions.

Evaluating supplier reliability is crucial for global buyers navigating the complexities of customizable coating machine selection. Recent market research highlights the importance of leveraging advanced analytics, such as machine learning (ML) and deep learning (DL), to enhance supplier selection processes. These technologies enable businesses to evaluate potential suppliers more effectively by analyzing vast amounts of data to predict reliability, quality, and performance. According to industry insights, organizations that utilize AI-driven supplier identification services can significantly improve their sourcing efficiency and minimize risks associated with supplier volatility.

Furthermore, the manufacturing sector is increasingly recognizing the need for a strategic approach to procurement. A report indicates that companies focusing on digital investments in their supply chain management can achieve greater innovation and resilience in the face of disruptions. By integrating these advanced data analytics into their procurement strategies, firms can uncover valuable insights that drive better decision-making, ultimately transforming supplier relationships into strategic partnerships. As the landscape evolves, businesses that invest in evaluating their suppliers through data-driven methods will find themselves better equipped to meet the challenges of a competitive global marketplace.