Choosing the perfect Double-Sided Coating Machine can be daunting. Industry expert, Dr. Emily Hartman, emphasizes, "Understanding your specific needs is crucial before making a purchase." Each machine varies in features and capabilities.

When assessing options, consider your production volume and the types of materials. Machines come with different coating technologies, affecting performance. A machine that suits one manufacturer may not meet another's demands.

Some machines are overly complex, with features that may go unused. Reflect on your operations and future needs. Remember, the right Double-Sided Coating Machine should enhance efficiency, not complicate processes. Investing time in research is vital for long-term success.

When exploring double sided coating machines, it's essential to understand the various types available in the market. Generally, these machines can be categorized into three main types: roller coaters, spray coaters, and curtain coaters. Each type has its unique application and performance characteristics.

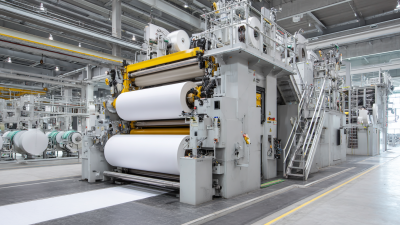

Roller coaters are among the most commonly used machines. They apply coatings through a series of rollers. According to industry reports, roller coaters can achieve an 80% coating efficiency, making them suitable for high-volume production. However, they may struggle with thicker coatings, requiring a different approach for optimal results.

Spray coaters, on the other hand, offer versatility. They can handle various viscosity levels and provide a more uniform finish. Research shows that spray coaters can reduce material waste by up to 30%. However, achieving the perfect spray pattern requires consistent adjustments. Curtain coaters are ideal for thin coatings and can provide high-speed application. Yet, these machines might have difficulties achieving consistent results on uneven surfaces.

Understanding these types will help you choose a machine that aligns with your production needs. Selecting the wrong type could lead to inefficiencies or wasted resources, highlighting the importance of thorough consideration.

| Type | Coating Method | Max Width | Production Speed | Suitable Materials | Cost Range |

|---|---|---|---|---|---|

| Roll Coater | Roll-to-Roll | 1000 mm | 20 m/min | Plastic films, Papers | $10,000 - $25,000 |

| Spray Coater | Spray Application | 800 mm | 15 m/min | Metals, Plastics | $15,000 - $30,000 |

| Dip Coater | Dipping | 600 mm | 5 m/min | Ceramics, Glass | $5,000 - $15,000 |

| Blade Coater | Blade Application | 1200 mm | 25 m/min | Papers, Foils | $12,000 - $28,000 |

When selecting a double-sided coating machine, key features are crucial. First, consider the coating speed. Machines can vary widely, with speeds from 30 to 200 meters per minute. For higher production demands, opt for models that offer faster speeds. Efficiency can greatly impact your bottom line.

Material compatibility is another vital feature. Different machines excel with specific materials. Whether you’re working with metal, plastic, or paper, ensure the machine you choose supports these substrates. According to industry reports, compatibility can enhance the quality of the final product.

Tips: Look for machines with adjustable settings. This allows greater control over the coating thickness, essential for precision work. Regular maintenance is also vital; a well-maintained machine extends its lifespan significantly.

Another feature to weigh is automation level. Advanced machines can automate processes, reducing labor costs. Research shows that fully automated systems can improve productivity by up to 30%. However, some operators might feel overwhelmed by complexity. Balancing technology with user-friendliness is essential for effective operations.

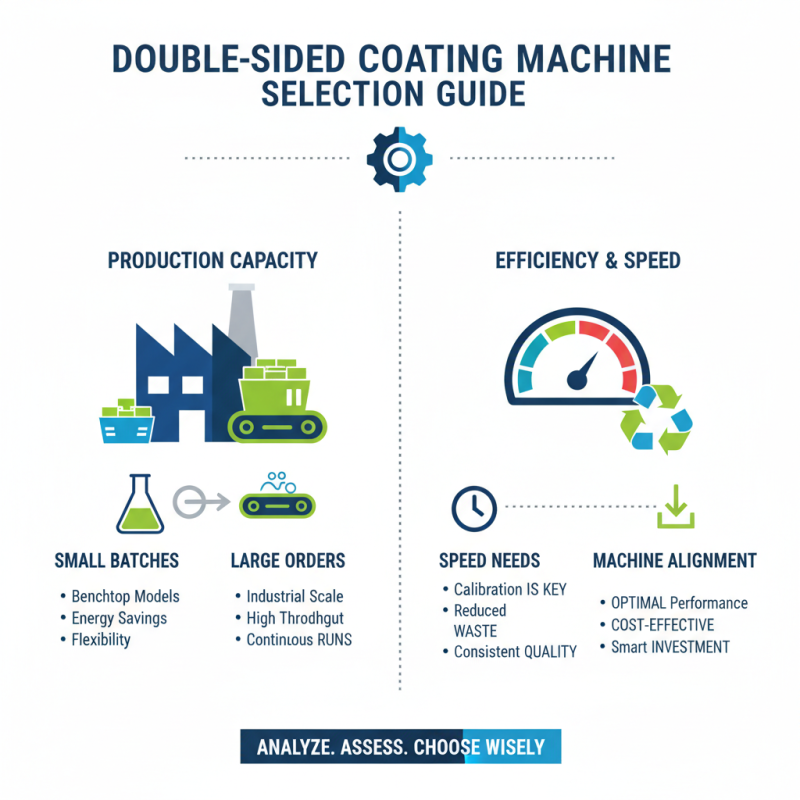

When choosing a double-sided coating machine, understanding your production capacity is crucial. Analyze your output requirements. Are you working on small batches or larger orders? Each type demands different machines. A machine suited for high volume may waste energy if used for smaller tasks. Assessing efficiency is equally important. Choose machines that align with your speed needs. A faster machine may seem tempting, but it could lead to increased waste if not properly calibrated.

Tips: Regular maintenance is vital. Ensure that your machine runs smoothly. This not only prolongs its life but also maintains efficiency. Also, consider your workspace. A bulky machine can disrupt workflow. Find a balance between capacity and space.

Many options exist, but not all will meet your standards. Reflect on past projects. Did you face issues with output speed or product quality? This can guide your decision-making process. A thoughtful choice today can save time and resources later. Balancing your production capacity with the right machine is key. Make sure to scrutinize each option closely before deciding.

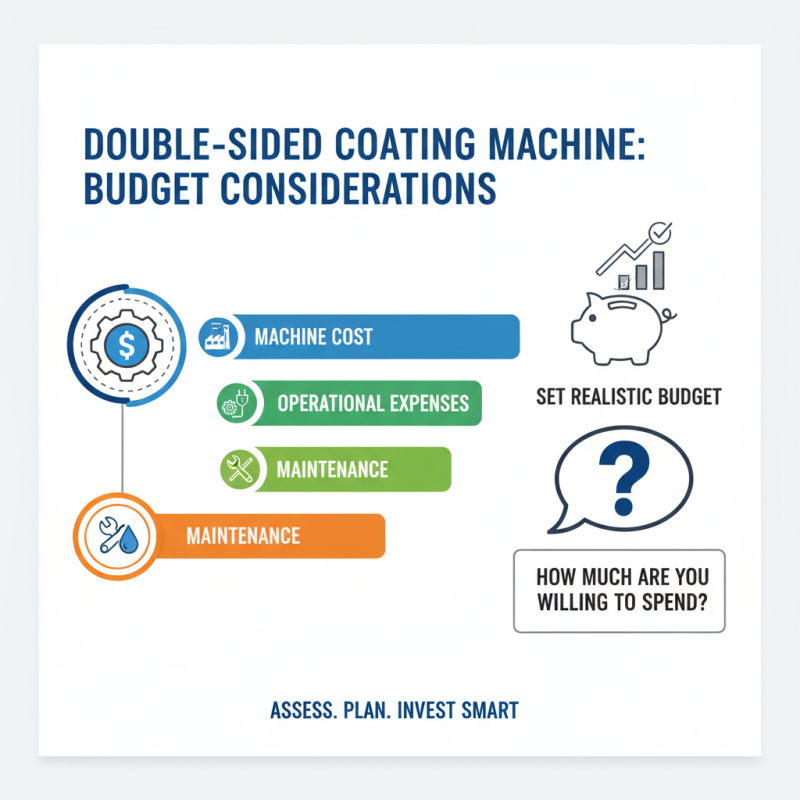

Choosing the right double sided coating machine requires careful consideration of your budget. It’s essential to assess how much you are willing to spend. Set a realistic budget that includes machine cost, operational expenses, and maintenance.

Cost-effectiveness is key. A more expensive machine might promise better performance, but does it fit your production needs? Analyze the features you truly need. Sometimes, machines with flashy options can be unnecessary. Focus on essential capabilities for your production process.

Reflect on long-term expenses as well. Cheaper options may save money upfront, but could incur higher maintenance costs. Analyze the trade-offs. Are you willing to sacrifice quality for a lower price? Think through these questions before making a decision.

Maintaining a double-sided coating machine requires attention to detail.

Regular cleaning is essential. Dust and residue can affect coating quality.

Schedule routine inspections every few months. This helps identify wear and tear early.

Support is equally critical. Many users overlook the need for training. Proper training ensures operators understand

the machine's functions. This prevents mishaps and prolongs the machine's life. Operators should feel confident using the equipment.

It's important to have access to reliable support services. Quick assistance can minimize downtime.

An inefficient response can lead to longer production delays. Reflecting on maintenance practices could reveal areas for improvement.

Consistency in maintenance habits ultimately enhances machine performance.