Choosing the right Lithium Battery Coating Machine is crucial for manufacturers. As industry expert Dr. Emily Chen states, "The right machine can significantly enhance performance." Selecting the best coating machine requires careful consideration of various factors.

Lithium battery production demands precision and efficiency. A quality coating machine ensures an even application of materials, which influences battery longevity and energy capacity. However, not all machines are created equal. Some may lack precision, leading to uneven coatings that diminish battery performance.

Moreover, technological advancements constantly change the market landscape. Manufacturers face challenges in keeping up with the latest innovations. Investing in a Lithium Battery Coating Machine with outdated features may hinder competitiveness. Reflecting on individual needs and production goals is essential for making an informed decision.

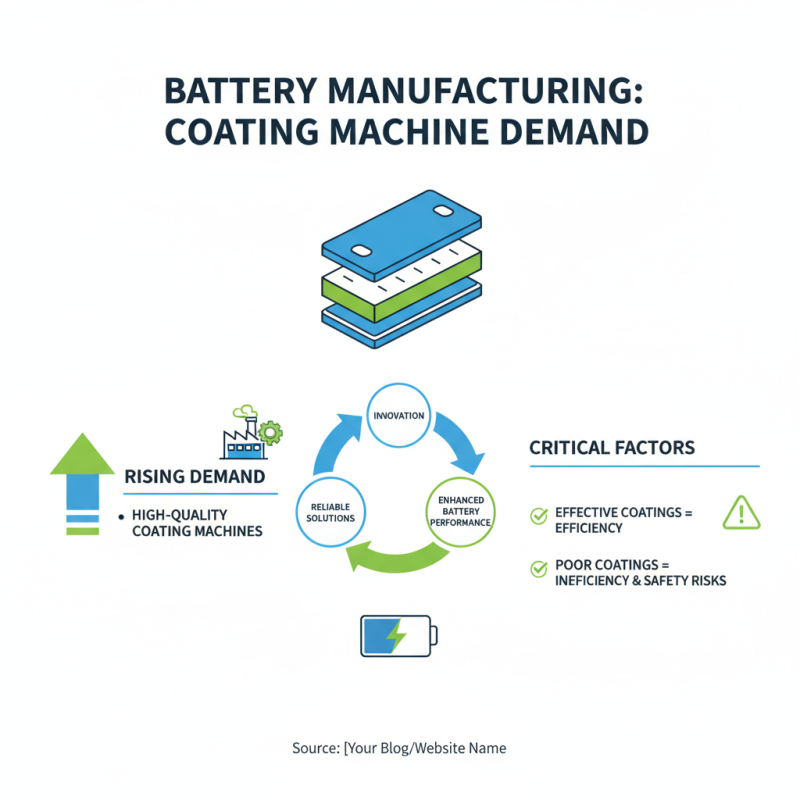

The coating process is crucial for lithium batteries. It significantly impacts battery performance and lifespan. Coating materials influence energy density, thermal stability, and overall efficiency. Reports indicate that a well-coated battery can enhance energy density by over 20%. That's substantial. The right coating can reduce friction and improve ion flow.

Yet, choosing the correct machine for this process is challenging. Various machines produce different results. Some may coat unevenly, leading to inconsistencies. This could decrease battery reliability. A study highlighted that a lack of precision in coating can reduce cycle life by up to 30%.

Moreover, the application method matters too. Different technologies, such as slot-die and spray coating, yield distinct outcomes. Each method has pros and cons. Understanding these nuances is critical. Innovations in coating technology are on the rise. However, the market lacks standardized solutions. This situation calls for careful research and trial runs. Seek ways to fine-tune both the machine and the process.

Choosing a lithium battery coating machine involves careful consideration of various specifications. One key factor is the coating thickness control. Precise control ensures that batteries meet performance standards without excessive material waste. A machine with adjustable thickness settings can adapt to different requirements, maximizing efficiency.

Another essential consideration is the speed of the coating process. Machines that offer faster coating times can improve overall productivity. However, it's crucial to balance speed with the quality of the coating. A machine that applies coatings too quickly might compromise the evenness and durability, leading to potential failures.

The cleanliness and maintenance of the machine are also crucial. A system that is hard to clean can accumulate residues, affecting product quality. While some machines may have complex designs, simpler systems might require more attention in terms of upkeep. Always evaluate the ease of maintenance, as it's vital for long-term efficiency. This process can be daunting, and reflecting on these factors will help in making a more informed decision.

| Specification | Description | Importance |

|---|---|---|

| Coating Thickness | The ability to control the thickness of the coating applied to the battery cells. | Ensures optimal performance and longevity of the battery. |

| Production Speed | The rate at which the machine can coat battery cells, often measured in square meters per hour. | Affects overall productivity and manufacturing efficiency. |

| Compatibility | The range of materials that the coating machine can work with. | Ensures versatility and adaptability for different battery chemistries. |

| Control Systems | Advanced control mechanisms for precise coating applications. | Enhances uniformity and consistency of the coating process. |

| Energy Efficiency | The amount of energy consumed relative to the output produced. | Reduces operational costs and environmental impact. |

| Maintenance Requirements | The frequency and complexity of maintenance needed for optimal operation. | Affects downtime and long-term operational reliability. |

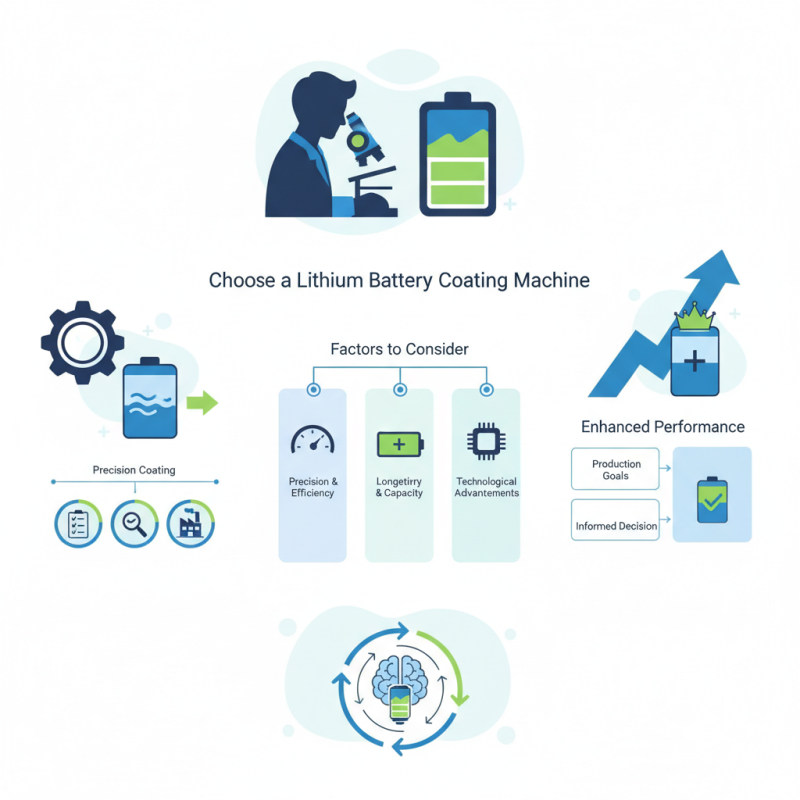

The demand for high-quality coating machines in battery manufacturing is on the rise. As the industry continues to innovate, manufacturers require reliable solutions. Battery performance hinges on effective coatings. Poor quality could lead to inefficiency and safety issues.

When choosing a lithium battery coating machine, consider these aspects. Evaluate the machine's consistency in applying coatings. A non-uniform layer can affect battery life. Next, look into automation features. Automation boosts efficiency but may add complexity. Striking a balance ensures productivity without unnecessary complications.

Tips to consider: Assess maintenance needs before making a purchase. A machine that requires frequent servicing may disrupt production. Also, keep an eye on market trends. Staying updated can help you adapt to emerging technologies. Ultimately, the right coating machine is crucial for both performance and safety in battery manufacturing.

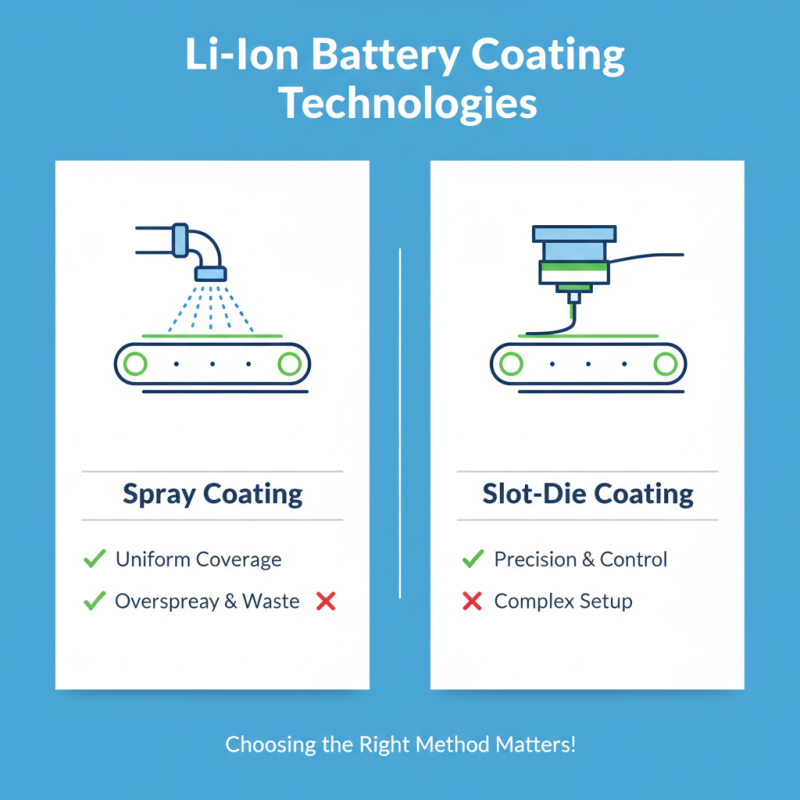

When choosing a lithium battery coating machine, it’s vital to understand the various coating technologies available. Each method has its advantages and drawbacks. For example, traditional spray coating can provide uniform coverage. However, it may lead to overspray and waste. Alternatively, slot-die coating offers precision but often requires more complex setup. This can frustrate new operators.

Tips: Consider your production volume. If you need high output, think about machines that support roll-to-roll processes. This method often enhances efficiency.

Another technology, dip coating, is straightforward in its approach. It can be cost-effective for small batches. Yet, achieving consistent thickness remains a challenge. Operators must monitor parameters closely. Ultimately, the right choice depends on specific production needs and available technologies.

Tips: Always weigh the long-term costs. Maintenance and downtime can impact your operation significantly. Avoid opting for equipment based solely on price. Performance and reliability are equally important.

Investing in advanced lithium battery coating equipment can significantly impact production efficiency and product quality. According to a recent industry report, manufacturers can see up to a 30% increase in throughput with modern coating machines. This improvement translates to higher revenue. However, the initial costs for such equipment can be daunting.

Consider a facility that upgrades its coating machines. The payback period can be as short as 18 months if production ramps up effectively. Yet, many companies hesitate. They fear the upfront investment without guarantees of increased demand. Evaluating operational costs versus potential gains is crucial. A 2022 analysis highlighted that companies adopting new technology saw a 15% rise in profit margins.

Despite these numbers, some producers still cling to older machines. These older systems might seem cheaper but could lead to higher long-term costs due to inefficiency. Delays in production can erode profit margins. The trade-off between initial expense and future benefits requires careful thought. Achieving a balance may not be straightforward, but the data indicates the potential for significant returns.