Choosing the right Leather Coating Machine is crucial for businesses aiming to enhance their production efficiency and product quality in the leather industry. According to a report by Grand View Research, the global leather market is projected to reach $371 billion by 2025, underscoring the rising demand for high-quality leather products. This growth necessitates the adoption of advanced technologies, such as state-of-the-art leather coating machinery, which can significantly improve the aesthetic appeal and durability of leather goods. Furthermore, recent statistics from Research and Markets indicate that the leather coating machine market is expected to grow at a compound annual growth rate (CAGR) of 6.2% over the next five years, highlighting the importance of selecting the right machinery for competitive advantage. As businesses navigate this expanding landscape, understanding the features and functionalities of various leather coating machines is essential for optimizing production processes and meeting consumer expectations.

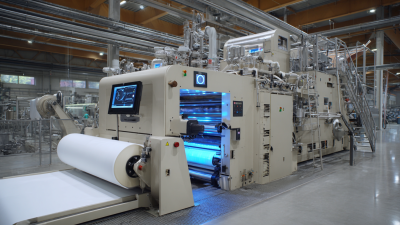

When choosing a leather coating machine for your business, it is essential to understand the various types available in the market. The primary categories include spray machines, roller coating machines, and dipping machines, each suited for different applications and coating finishes. Spray machines are versatile and ideal for intricate designs, while roller coating machines provide consistency and are excellent for larger production runs. Dipping machines offer a thorough coating but may require careful handling of materials to ensure even application.

When choosing a leather coating machine for your business, it is essential to understand the various types available in the market. The primary categories include spray machines, roller coating machines, and dipping machines, each suited for different applications and coating finishes. Spray machines are versatile and ideal for intricate designs, while roller coating machines provide consistency and are excellent for larger production runs. Dipping machines offer a thorough coating but may require careful handling of materials to ensure even application.

Tips: Consider the specific needs of your production process. If you require flexibility in design and swift changeovers, a spray machine might be the best fit. Conversely, if your focus is on steady output and uniformity, investing in a roller machine could streamline operations effectively. Don’t overlook the importance of safety features, especially in high-volume environments where cut hazards may be present.

Also, evaluate the machine’s ease of use and maintenance requirements. Look for models that include intuitive controls and are equipped with adequate support for consistent operation. Close attention to these factors will not only improve productivity but will also enhance the quality of your leather products.

When selecting the right leather coating machine for your business, evaluating your production needs is paramount. Capacity is one of the first aspects to consider. According to a report from the International Leather Maker, the global leather production capacity is projected to reach over 2 billion square meters by 2025. This indicates that your machine should be able to handle high-volume output to keep pace with industry demands. If your production does not meet this capacity, a smaller, more specialized machine may be appropriate.

Next, speed is crucial in ensuring that your operations remain efficient. Studies show that high-efficiency coating machines can increase production speed by up to 30%, a significant factor given that delays in manufacturing can lead to missed deadlines and lost business opportunities. Moreover, size considerations also play a role in this decision. The workspace available and the machine's footprint in your facility can affect overall productivity. A comprehensive analysis of your space and the dimensions of the machine will help optimize the workflow. Balancing these factors will ultimately assist in choosing the ideal coating machine for your leather production needs.

| Machine Type | Production Capacity (sq. ft./hour) | Speed (m/min) | Size (L x W x H in cm) | Power Requirement (kW) |

|---|---|---|---|---|

| Single Pass Machine | 500 | 10 | 200 x 80 x 150 | 15 |

| Multi Pass Machine | 800 | 12 | 250 x 90 x 160 | 20 |

| Compact Coater | 300 | 8 | 150 x 60 x 140 | 10 |

| High-Speed Mrch | 1000 | 15 | 300 x 120 x 170 | 25 |

When selecting a leather coating machine for your business, the key features to prioritize include technology and efficiency. Advanced automation plays a crucial role in modern equipment, much like the transformation seen in the garment industry, which is increasingly influenced by robotics and AI. Efficiency in operations can significantly reduce production time and costs, allowing businesses to respond rapidly to market demands.

Consider machines equipped with precision coating technologies that ensure consistent coverage and quality. Innovations such as automated speed settings and integrated monitoring systems enhance operational efficiency. Reports indicate that companies utilizing advanced coating machines can achieve up to a 30% reduction in waste materials, which not only saves money but also supports sustainability efforts within the industry.

Tips: Always assess the compatibility of the leather coating machine with various leather types to ensure versatility in application. Additionally, look for machines that offer easy maintenance and support services, as this can greatly affect long-term productivity and machine lifespan. Investing in the right technology can pave the way for growth and sustainable practices in your leather business.

When budgeting for a leather coating machine, it's essential to consider not only the initial costs but also ongoing maintenance expenses and the overall return on investment (ROI). The price of these machines can vary significantly based on features, capacity, and brand. It's crucial to analyze your business needs to determine the right investment level that aligns with your production goals. Additionally, finding a machine that offers reliable performance and durability can save you from frequent repairs and replacements, ultimately impacting your bottom line.

Maintenance costs should be factored into your budget from the outset. Regular servicing is necessary to keep the machine running efficiently and to prolong its lifespan. Investing in a machine with readily available parts and manufacturer support can lower long-term maintenance costs. Furthermore, a well-maintained leather coating machine increases productivity and enhances product quality, which contributes positively to ROI. By assessing these factors thoughtfully, you can make a well-informed decision that balances initial investment with sustainable growth potential for your business.

When choosing a leather coating machine for your business, the supplier's reputation and support services can play a critical role in ensuring long-term success. A recent industry report indicated that companies with strong supplier relationships experience up to 25% less downtime because of effective support and maintenance services. This highlights the importance of assessing potential suppliers not just on product quality but also on their ability to provide timely assistance and training.

Furthermore, evaluating the supplier's reputation in the market is essential. According to a survey conducted by the Leather Industry Association, businesses that partner with reputable suppliers report a 30% increase in productivity, largely due to reliable equipment and ongoing technical support. Engaging in discussions with existing clients of the supplier can provide invaluable insights into their reliability and service quality. It’s beneficial to look for suppliers who offer comprehensive warranties and accessible technical support, as this can significantly enhance operational efficiency and foster a productive working relationship.