Choosing the right film coating machine can significantly impact your production process. These machines are crucial for various industries, from pharmaceuticals to food packaging. A suitable film coating machine enhances product quality and efficiency.

When selecting a film coating machine, consider your specific needs. Different machines offer varying capabilities and features. It's essential to analyze the types of films you plan to use and the quantities required. Moreover, factors like ease of use and maintenance should not be overlooked.

Many buyers overlook the importance of compatibility and flexibility. A machine that fits your current needs may not serve you well in the future. Reflecting on potential growth and changes in production demands is vital. Making informed decisions can prevent costly mistakes later on.

Film coating machines play a crucial role in various industries, particularly in pharmaceuticals and food. These machines apply a thin layer of polymer-based coating to particles. This enhances stability, taste, and appearance. According to a recent industry report by Smithers Pira, the global market for film coating technologies is projected to reach $3.99 billion by 2024, with a compound annual growth rate (CAGR) of 6.5%. These statistics highlight their growing importance in production processes.

The selection of the right film coating machine depends on specific needs. Factors include speed, coating uniformity, and the types of materials used. It’s essential to assess your production volume. Machines designed for high throughput often come with higher initial investments, which may not always justify the increase in efficiency. Feedback from users reveals that some machines can create uneven coatings, leading to potential product inconsistencies.

Investing in a film coating machine isn’t just about size and speed. Many operators report issues related to maintenance and ease of operation. A complex machine might require more training, impacting overall productivity. Balancing these elements is critical for long-term success. Understanding your unique requirements will guide you toward the best choice.

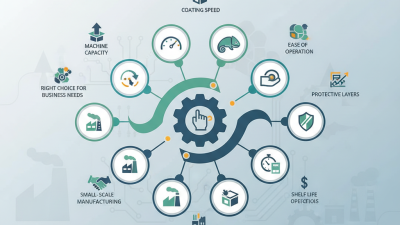

Choosing the right film coating machine requires careful consideration of key features. Start with the machine's capacity. It should align with your production goals. A machine that is too small will slow you down. Conversely, an overly large machine may waste resources.

Pay attention to the coating technology. There are various types of coating methods, like pan, spray, or fluid bed. Each method has its pros and cons. Evaluate your product type and desired finish. Not all machines perform equally well.

Tips: Look for machines with easy maintenance. Regular upkeep is vital for longevity. This can save time and reduce costs. Also, consider the machine's footprint. Space constraints can limit your choices.

Don’t overlook the importance of control systems. A user-friendly interface can streamline operations. Complicated systems can lead to errors. It’s essential to provide adequate training for your team.

Think about flexibility too. Can the machine handle different materials? This feature can enhance your production capabilities.

Be aware that choosing a machine is not simple. Research is crucial. Engage with experts if possible. Take the time to weigh all options carefully. Make sure you reflect on your unique needs.

Assessing your production needs is crucial when selecting a film coating machine. Start by evaluating the volume of production you anticipate. Machines vary widely in capacity. Consider if you need a high-output machine for large batches or a smaller one for more specialized tasks. Analyze your workflow to determine which machine fits best.

Tips can guide you in the selection process. Look into the speed of the machine. A faster machine can enhance productivity but may come with a higher price tag. Watch for potential trade-offs. Maintenance costs often increase with high-speed machines. Also, consider space requirements. Can your facility accommodate a larger machine?

Don’t forget the product type you’ll be coating. The requirements differ based on materials and intended use. Testing compatibility is essential. You may encounter issues with certain combinations. Finally, keep in mind the learning curve for your team. New machines may require training and adjustment, impacting your production timeline.

| Model | Max Production Capacity (units/hour) | Coating Thickness Range (µm) | Weight (kg) | Power Consumption (kW) | Price Range (USD) |

|---|---|---|---|---|---|

| Model A | 200 | 5 - 15 | 150 | 10 | $25,000 - $30,000 |

| Model B | 150 | 3 - 12 | 120 | 8 | $20,000 - $25,000 |

| Model C | 250 | 4 - 10 | 200 | 12 | $28,000 - $35,000 |

| Model D | 100 | 2 - 8 | 100 | 5 | $15,000 - $18,000 |

When evaluating film coating machines, the balance between cost and quality is crucial. A cheaper machine might seem appealing at first. However, low initial costs can lead to higher maintenance expenses. With poor quality, you may face inconsistent results. This can affect your production significantly.

Quality machines generally offer better performance and durability. They can handle larger workloads with less downtime. However, they come with a higher price tag. It's essential to analyze the long-term benefits. Sometimes, spending more upfront saves money over time. It’s worth considering the machine's reliability and support services offered.

Focus on your specific needs. A machine that fits one project may not suit another. Perform rigorous evaluations. Look at user feedback and test runs, if possible. A rushed decision can lead to regret. Ultimately, finding the right balance is key to maximizing your investment.

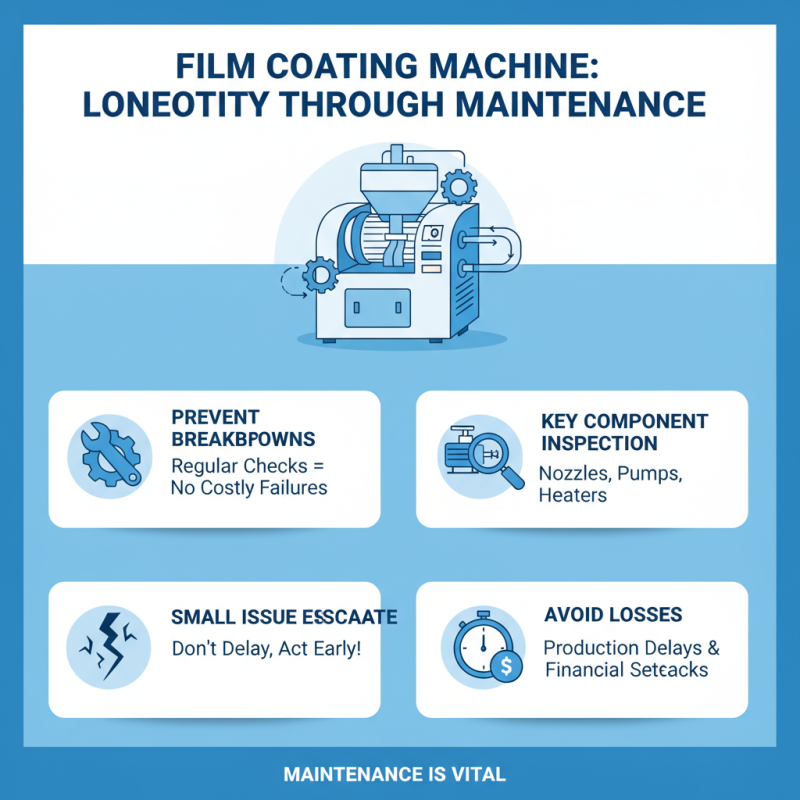

Maintenance is vital for the longevity of your film coating machine. Regular checks can prevent costly breakdowns. Inspect key components like nozzles, pumps, and heaters. A small issue may escalate if left unattended. This could lead to production delays and financial losses.

Establish a cleaning schedule to keep your machine in top condition. Dust and residue can affect performance. Use appropriate cleaning agents that won't damage your equipment. Track wear and tear over time. This helps you anticipate when parts need replacing. Documenting these issues may reveal patterns you hadn’t noticed.

Support is equally crucial. Having access to knowledgeable technicians can save you time. They can offer guidance on troubleshooting common problems. Consider joining user forums to share experiences and gather tips. You might find that others have faced similar challenges. Their solutions may not always be perfect, but they can provide valuable insights.