In the rapidly evolving packaging industry, selecting the right PET Coating Machine is crucial. According to a recent industry report by Smith & Partners, the demand for PET packaging solutions has surged by 35% in the past three years. This growth highlights the need for efficient and reliable coating machines. As noted by industry expert Dr. Emily Chen, "Choosing the right PET Coating Machine can considerably impact production efficiency and product quality."

When considering a PET Coating Machine, several factors come into play. These include production speed, coating uniformity, and machine reliability. A high-performance machine not only enhances output but also ensures optimal surface quality. However, many manufacturers still struggle to balance cost with advanced technology. The choices can be overwhelming, leading to potential missteps in the decision-making process.

Moreover, the technology behind PET Coating Machines is not static. Continuous innovation can make previously chosen models obsolete. Companies must be prepared to adapt and rethink their existing machinery. Investing in the right technology can mean the difference between success and stagnation in a competitive market.

PET coating machines play a critical role in various industries, including packaging, electronics, and textiles. They apply a layer of polyethylene terephthalate (PET) to materials. This increases durability, moisture resistance, and enhances aesthetics. According to industry reports, the global demand for PET-coated products is projected to reach 1.5 million tons by 2025. This growth indicates a robust market for PET coating applications.

Choosing the right PET coating machine involves understanding specific applications. Different machines cater to various needs, from thin film coatings to thicker applications for packaging. Industry data highlights that packaging accounts for nearly 60% of PET use, emphasizing its significance. Factors like machine speed, coating thickness, and technological features must align with production requirements.

However, not all machines are suitable for every application. It’s important to evaluate the compatibility of the coating material with your intended use. Some machines may struggle with thicker coatings or faster speeds. Investing in a machine that does not meet your needs can lead to inefficiencies. Businesses must reflect on their unique requirements and production goals before making a decision. This thoughtful approach can prevent costly mistakes and ensure long-term success.

| Parameter | Description | Importance |

|---|---|---|

| Machine Type | Single or Double Sided | Critical for application needs |

| Coating Speed | Measured in meters per minute | Affects production rate |

| Max Width | Width of substrates that can be processed | Important for versatility |

| Heating Method | Hot Air, IR, or UV | Affects coating quality |

| Control System | Manual or Automated | Ease of operation |

| Energy Efficiency | Energy consumption rating | Cost-saving in long run |

| Maintenance Requirements | Frequency of upkeep needed | Reduces downtime |

| Price Range | Estimated cost of the machine | Budget considerations |

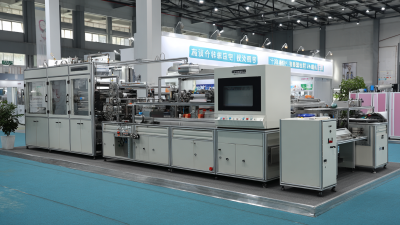

When selecting a PET coating machine, several key factors come into play. The size and scale of your production line should be evaluated first. Consider the dimensions of the machine and how it fits into your workspace. A larger machine might produce more output but could also increase operational complexities.

Next, think about the technology used in the machine. Different models employ various coating methods. Some techniques might be more effective for certain applications than others. Researching these techniques can help you make an informed decision. Make sure to analyze energy consumption as well, since efficiency can significantly impact long-term operational costs.

Maintenance is another crucial aspect. Some machines require more frequent service and repairs, while others are designed for durability. Understand the upkeep needed and how that fits with your production schedule. You might find that easy maintenance saves time but may not always come at the lowest upfront price. Balancing cost and functionality is essential, so be ready to reconsider your initial assumptions.

When selecting a PET coating machine, understanding different technologies is key. There are several types available. Each has unique features that cater to specific needs. For example, some machines use gravure coating technology. This method delivers excellent print quality. It works well for high-volume production.

Another option is roll-to-roll coating. This technology is flexible and efficient. It allows for continuous processing, making it suitable for large-scale operations. However, it can be challenging to adjust settings for various substrates. User feedback often points out these complexities.

Finally, some machines offer electrostatic coating technology. This method ensures even coverage and reduces waste. However, mastering this technology takes time. Users may face a learning curve. Each technology presents advantages and drawbacks. It’s crucial to assess your specific requirements carefully.

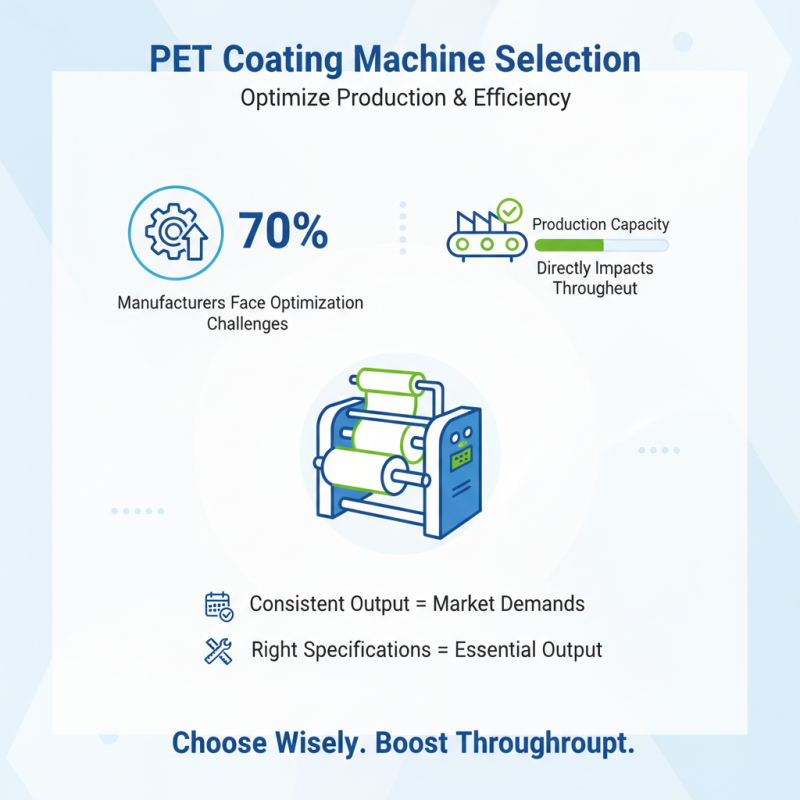

When choosing a PET coating machine, assessing production capacity and efficiency is crucial. Production capacity directly impacts throughput. A machine's ability to produce consistently is key for meeting market demands. Recent industry reports indicate that up to 70% of manufacturers face challenges in optimizing production rates. Therefore, selecting a machine with the right output specifications is essential.

Efficiency also plays a vital role. A machine that uses energy effectively can drastically cut costs. Studies show that machines with higher efficiency can save around 20% in operational expenses. However, some machines promise high efficiency but fail to deliver under real-world conditions. Users must evaluate actual performance data to confirm these claims.

Maintenance is another factor linked to efficiency. A well-maintained machine operates at peak capacity, yet many overlook regular upkeep. This can lead to a 15% drop in efficiency over time. It's important to reflect on maintenance schedules and adjust them as necessary. Finding the right balance between capacity and efficiency ensures that your production line remains competitive.

When evaluating the cost and maintenance of PET coating machines, several critical factors come into play. Initial investment costs vary widely. A basic model may start at around $50,000, while high-end machines can exceed $250,000. This disparity can influence your decision depending on your production scale. According to industry reports, the total cost of ownership can be misleading, as many overlook maintenance expenses, which can range from 5% to 15% of the machine's purchase price annually. This can quickly add up.

Maintenance requirements also significantly affect operating efficiency. Some machines require training and specialized knowledge for upkeep. Regular maintenance can help in reducing downtime. However, even the best-designed machines may experience unexpected breakdowns. Predictable costs can become unpredictable without a dependable service plan. A detailed service agreement can often provide clarity. But, companies sometimes dismiss it as an unnecessary expense until issues arise.

Understanding your unique production needs is essential. The choice may not just be about upfront costs. Balancing initial investment with long-term operational costs can lead to better decisions. Data shows that companies frequently overestimate their production demands. Over- or underinvesting in technology affects overall productivity. Therefore, it's beneficial to take a step back and evaluate your current and future needs meticulously.