In the fast-evolving world of manufacturing, the "Double-Sided Coating Machine" stands out as a game-changer. James Carr, a leading expert in coating technology, emphasizes, "Efficiency and precision are critical in modern production." This machine promises both, making it essential for many industries today.

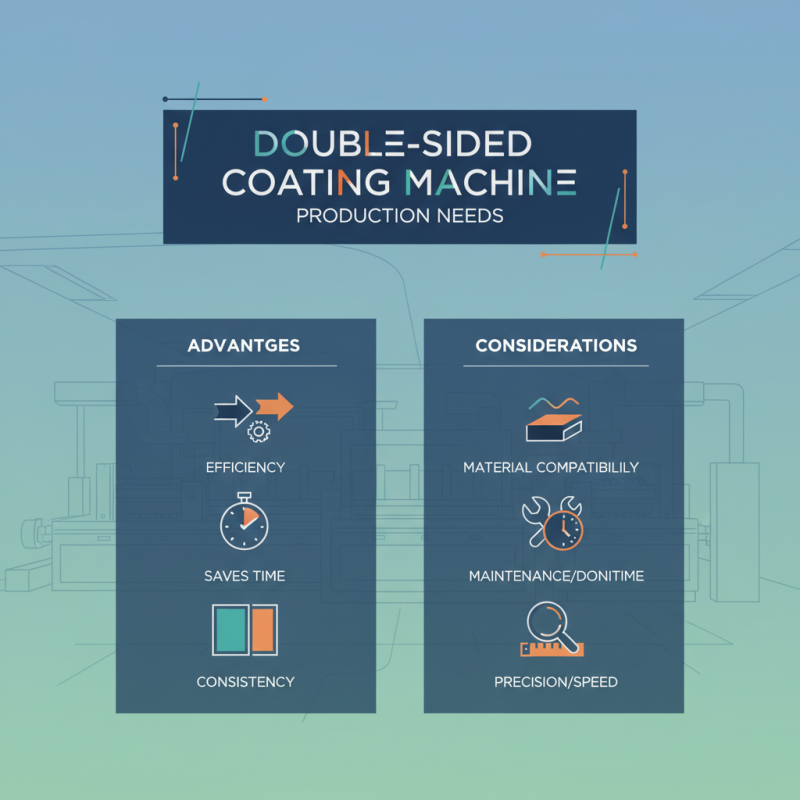

Choosing a double-sided coating machine can transform production lines. Its ability to apply coatings simultaneously on both sides ensures consistency and saves time. However, not all machines deliver the same results. Companies must weigh factors like precision, speed, and maintenance costs.

Many businesses have switched to double-sided machines, but challenges still arise. Some machines may not handle specific materials well, leading to quality concerns. Others may require frequent adjustments, causing downtime. Reflecting on these issues, manufacturers should approach their choices with caution. Each decision holds significant implications for productivity and cost-effectiveness.

Double-sided coating machines are gaining traction in manufacturing industries due to their unique advantages. The ability to apply coatings on both sides of a substrate can significantly increase efficiency. Studies show that using these machines can improve production speed by up to 40%. This efficiency boost results in reduced processing time and costs.

Moreover, double-sided coating provides uniformity. In industries like electronics and packaging, precision matters. A consistent coating on both sides ensures better performance and durability of products. Reports indicate that products with a uniform coating experience less wear and tear, enhancing their lifespan by approximately 20%. This is crucial, as manufacturers seek ways to improve product quality without inflating costs.

However, it's not all perfect. The initial investment in double-sided coating machines can be high. Some manufacturers hesitate to adopt this technology, fearing they won’t see quick returns. Maintenance can also be more complex compared to single-sided machines. Addressing these concerns is essential to fully leverage the benefits. Balancing cost and efficiency is a challenge that many companies face as they navigate advancements in manufacturing technology.

Double-sided coating technology offers remarkable efficiency for various production lines. It allows for the simultaneous application of coatings on both sides of a product. This method saves time and resources, enabling more streamlined operations. With precise control over the coating thickness, manufacturers can achieve consistent quality. The machine's flexibility handles different coating materials with ease.

One notable feature of double-sided coating machines is their ability to minimize waste. By optimizing the application process, excess materials are reduced. This leads to cost savings and a more sustainable production approach. Additionally, manufacturers can produce higher volumes without sacrificing quality. The ability to personalize coatings enhances product appeal.

Tip: Regular maintenance of the machine is crucial. Neglected equipment can lead to inconsistent results. Always check the calibration and cleanliness of the components. Consistency is key in maintaining product quality.

Nonetheless, it's essential to analyze your production needs before investing. The initial cost may be high, and not all products require double-sided coatings. Evaluate your production volume and product types thoroughly. Not every application will justify the switch to double-sided coating technology.

Double-sided coating machines have become essential in various industries, given their versatility and efficiency. In the automotive sector, for instance, these machines apply protective coatings on both sides of parts to enhance durability and reduce wear. According to a report by MarketsandMarkets, the global automotive coatings market is expected to reach USD 37.86 billion by 2026, reflecting a significant uptick in production needs. The ability to evenly coat components saves time and minimizes waste, which is crucial for manufacturers aiming to meet green initiatives.

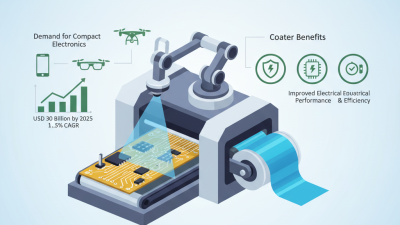

In electronics, double-sided coatings are instrumental in creating reliable circuits. The electronics industry relies heavily on precise and uniform applications. A study noted that the demand for double-sided coated substrates is rising, particularly with the shift toward thinner circuit designs. However, challenges remain. Achieving uniform coating thickness can be tricky, and inconsistencies can lead to defects, resulting in costly rework. Companies must continuously refine their processes to avoid these pitfalls and ensure quality.

Furthermore, in the construction industry, double-sided coatings are crucial for various applications, including insulation and waterproofing. They enhance building materials’ longevity. A report highlights that innovative double-sided solutions could potentially reduce construction waste by up to 30%. Yet, implementation can be challenging. Often, there is a gap between theoretical benefits and real-world performance. Continuous innovation and process evaluation are necessary to harness the full potential of these machines in diverse fields.

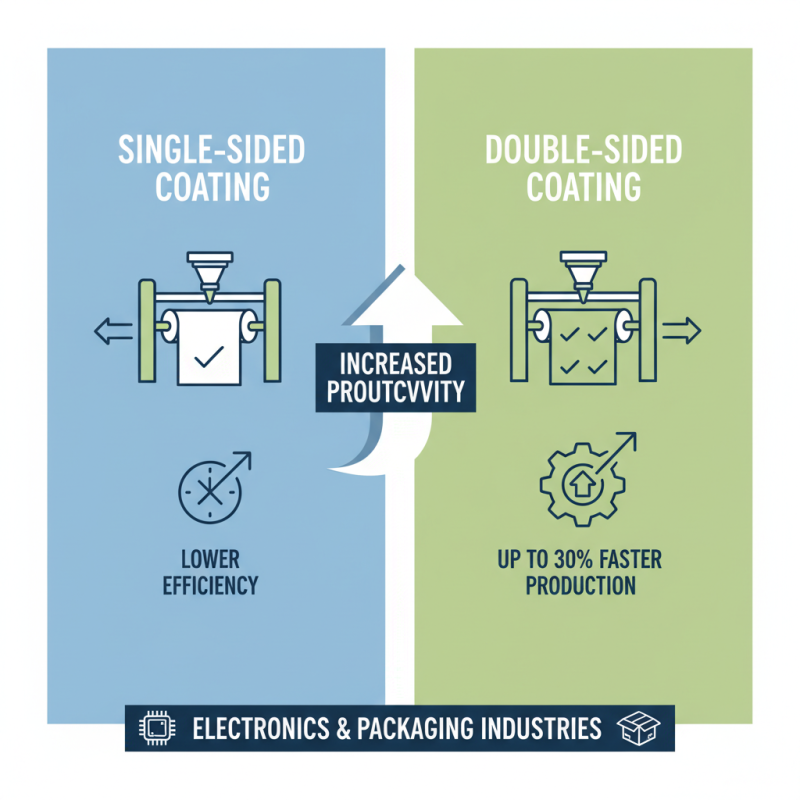

When it comes to coating machines, the choice between double-sided and single-sided options merits careful consideration. According to industry reports, double-sided coating machines can increase production efficiency by up to 30%. This efficiency stems from their ability to apply coatings on both sides of a substrate simultaneously. In sectors like electronics and packaging, this dual functionality reduces processing time and enhances product throughput, making it a vital component for manufacturers aiming to meet growing market demands.

On the other hand, single-sided coating machines may be less costly but often come with limitations. Their ability to only coat one side means longer cycle times and potentially higher labor costs. A report from the Coating Industry Association shows that single-sided machines can lead to a 20% increase in production time for certain materials. Many manufacturers find that while single-sided machines may suffice for simpler tasks, double-sided alternatives provide a clearer path to scaling operations.

Despite these advantages, investing in double-sided machines requires consideration of initial costs and complexity. Maintenance can be more demanding, requiring skilled technicians. Some manufacturers report challenges in training employees to effectively operate advanced systems. Thus, while the data may lean in favor of double-sided machines, the decision ultimately hinges on specific production goals and operational capabilities.

When selecting a double-sided coating machine, several factors demand attention. The machine’s capacity is vital. It should align with your production targets. Evaluate how much product you need to coat daily. A machine with inadequate capacity may lead to bottlenecks. Think about the types of coatings as well. Different applications may require specific machines. This choice can significantly affect the final product quality.

Another factor is the ease of use. Complex machines can increase training time and lead to errors. A user-friendly interface is essential. Employees should feel comfortable operating the machine. Maintenance is another concern. Machines that are difficult to service can lead to prolonged downtimes. Every minute counts in production.

It's also worth considering versatility. A machine that offers different coatings can be beneficial. However, too many options might confuse operators. Finding a balance is crucial. Look for machines that offer a good range of features without overwhelming complexity. Always think about how these factors align with your long-term production goals. Are you prepared for flexibility? Such questions can guide your final decision.