In the rapidly evolving landscape of modern printing, the role of precision machinery cannot be overstated. One critical innovation that stands at the forefront is the Comma Doctor Blade Coating Machine, which is revolutionizing the efficiency and quality of printed materials. As printing demands grow more complex, the need for automated, reliable, and adaptable coating solutions becomes paramount. This article delves into the transformative capabilities of Comma Doctor Blade Coating Machines, exploring how they optimize coating processes, reduce waste, and enhance overall product output. By embracing these advanced technologies, printing companies can not only streamline their operations but also meet the ever-increasing expectations of clients for high-quality, consistent results. Join us as we unlock the future of efficiency in printing through the lens of these remarkable machines.

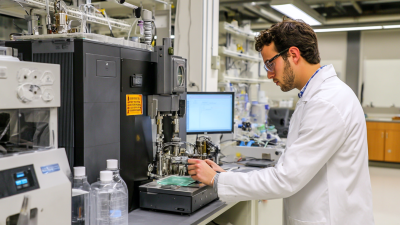

The role of doctor blade coating in modern printing technologies is becoming increasingly vital, particularly in enhancing print quality across various applications. This method has gained prominence not only in traditional printing industries but also in advanced sectors such as healthcare packaging. Recently, a state-of-the-art facility employing innovative air knife coating technology was introduced, marking a significant leap in the production of high-quality, sterile medical device packaging in the Asia Pacific region. This setup not only ensures consistency in coating thickness but also improves adhesion and surface characteristics, thereby elevating the overall print quality.

Furthermore, advancements in doctor blade technology are being explored in the realm of renewable energy, particularly in the production of perovskite solar cells. Research indicates that modifications in coatings and surface treatments can significantly enhance the stability and efficiency of these cells. By optimizing nucleation and crystallization processes during coating, researchers have been able to achieve more uniform films with fewer defects, directly influencing the performance of the final product. As the printing landscape continues to evolve, the importance of doctor blade coating becomes increasingly evident, paving the way for innovations that enhance print quality across diverse fields.

The modern printing industry is experiencing significant transformations driven by technological advancements, and comma doctor blade coating machines are at the forefront of this revolution. These machines have evolved to improve efficiency and precision, which are crucial for high-quality prints. Key innovations such as adjustable blade angles and advanced coating technologies allow printers to achieve a uniform application of coatings, ensuring better ink adhesion and reduced wastage. The integration of automated systems further enhances operational speed and consistency.

Tips: Investing in training on the latest comma doctor blade technology can significantly benefit your team. Proper understanding and use of the machine's features can lead to substantial productivity gains. Additionally, regular maintenance and timely upgrades can maximize the lifespan of your equipment and minimize downtimes.

Furthermore, developments in materials science are playing a pivotal role in the performance of comma doctor blade systems. New blade materials that resist wear and degradation improve durability, while advanced coatings facilitate smoother operations and greater adaptability to different printing substrates. These innovations not only enhance productivity but also open up avenues for creative applications in the printing process.

Tips: Always stay informed about emerging materials and technologies in the industry. Engaging with supplier representatives can provide insights into the best practices and innovative solutions available to optimize your printing operations.

Upgrading to advanced comma doctor blade coating machines offers significant operational benefits that can transform the printing process. These state-of-the-art machines are designed to optimize coating application with precision, ensuring an even distribution of ink or coating material across various substrates. This improved accuracy not only enhances the quality of the final product but also reduces waste, leading to cost savings and more sustainable practices in the long run.

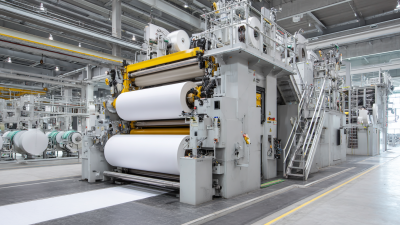

Moreover, modern coating machines come equipped with advanced automation features that streamline production workflows. By minimizing manual intervention, these machines help to reduce human error while increasing overall efficiency. This means faster turnaround times and the ability to meet high-volume demands without compromising quality.

With the integration of smart technologies, operators can also monitor performance in real-time, enabling proactive maintenance and reducing downtime. As companies look to enhance their competitiveness in the printing industry, investing in advanced coating machines becomes a pivotal step towards achieving operational excellence.

The integration of automation in comma doctor blade coating machines is revolutionizing the printing industry, facilitating seamless processes that enhance efficiency and productivity.

According to a report by Smithers Pira, the global print market is projected to reach approximately $980 billion by 2025, with automation playing a crucial role in this growth. By incorporating automated systems, printers can minimize human error, reduce downtime, and ensure consistent quality, leading to significant cost savings over time.

The adoption of intelligent technology in coating machines also enables real-time monitoring and adjustment of the printing process. Data from the Freedonia Group indicates that advanced automation technologies can improve operational efficiency by over 30%, allowing companies to respond swiftly to market demands. Automated doctor blade systems ensure precise ink application, which is vital for high-quality prints and reduces waste material.

As the industry continues to embrace these innovations, the future of printing looks brighter and more streamlined, setting a new standard for quality and efficiency.

The adoption of Comma Doctor Blade systems in modern printing has demonstrated significant improvements in efficiency and quality across various case studies. For instance, a leading European packaging company implemented the Comma Doctor Blade technology during their flexographic printing processes. By doing so, they achieved a remarkable 30% reduction in ink consumption, which not only cut costs but also reduced waste, aligning with their sustainability goals. The ease of adjusting the blade gap facilitated faster changeovers between jobs, enabling the company to enhance their productivity while maintaining print quality.

Similarly, a prominent textile printing firm in Asia successfully integrated Comma Doctor Blade systems to address challenges related to consistency and color saturation. The company reported a drastic decrease in color variation across runs, thanks to the precise control offered by the Comma technology. As a result, customer satisfaction surged, leading to increased repeat business. These implementations underline how Comma Doctor Blade systems are reshaping the industry, providing tangible benefits that drive both profitability and environmental responsibility in contemporary printing operations.

| Case Study | Industry | Implementation Year | Efficiency Improvement (%) | Key Benefits |

|---|---|---|---|---|

| Packaging Solutions | Packaging | 2021 | 30 | Reduced waste, faster production |

| Labeling Innovations | Labeling | 2020 | 25 | Higher accuracy, reduced downtime |

| Commercial Printing | Printing | 2019 | 40 | Improved color consistency |

| Flexible Packaging | Flexographic | 2022 | 35 | Cost reduction, enhanced quality |

| Specialty Coatings | Coating | 2023 | 45 | Enhanced durability, faster drying times |