In today's fast-paced manufacturing environment, maximizing efficiency is crucial for success, especially in the realm of coating technologies. According to industry expert Dr. Emily Chen, a leading authority on Hot Melt Coating Machines, "The efficiency of your production line hinges on how well you can adapt and optimize your coating processes." With the growing demand for high-quality, durable coatings across various sectors, understanding and implementing essential tips can significantly impact productivity.

Hot Melt Coating Machines have revolutionized how products are coated, offering advantages such as quick drying times and superior adhesion. However, many manufacturers still struggle to fully harness the potential of these machines. By focusing on best practices, companies can improve their operational performance and deliver exceptional products. This article delves into seven essential tips aimed at maximizing efficiency when using Hot Melt Coating Machines, ensuring that manufacturers can stay at the forefront of innovation and meet the ever-increasing market demands effectively.

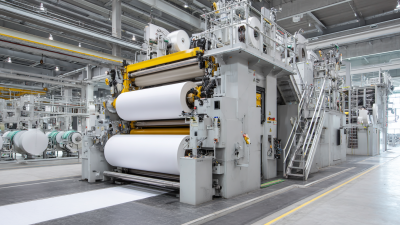

Hot melt coating machines are intricate systems that rely on several key components to function optimally. Understanding these components is crucial for attaining maximum efficiency and achieving high-quality results. The heating unit is one of the most vital parts, as it ensures that the thermoplastic materials reach the required viscosity for effective application. Proper calibration of the heating mechanisms can prevent issues such as overheating, which can lead to material degradation, and underheating, which can affect the adhesive qualities of the coating.

Hot melt coating machines are intricate systems that rely on several key components to function optimally. Understanding these components is crucial for attaining maximum efficiency and achieving high-quality results. The heating unit is one of the most vital parts, as it ensures that the thermoplastic materials reach the required viscosity for effective application. Proper calibration of the heating mechanisms can prevent issues such as overheating, which can lead to material degradation, and underheating, which can affect the adhesive qualities of the coating.

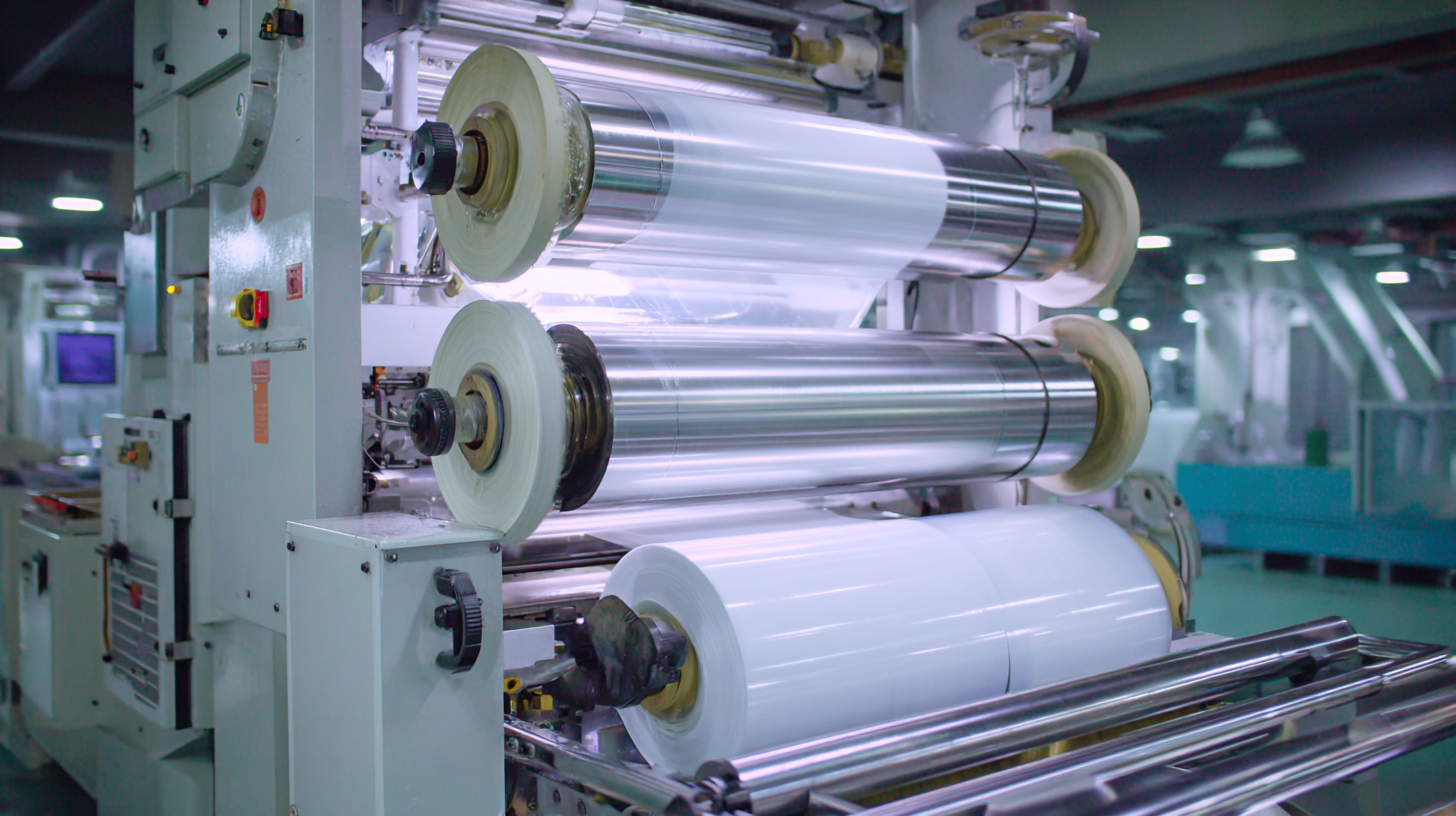

Another essential component is the application system, which includes the nozzle and the control mechanisms. Selecting the right nozzle size and type is critical in determining the coating thickness and uniformity. Additionally, precise control systems allow operators to adjust flow rates and speeds, ensuring that the coating is applied consistently across various substrates. Regular maintenance and cleaning of these components also play a significant role in the longevity and efficiency of hot melt coating machines, preventing blockages and ensuring smooth operation. By focusing on these key elements, users can optimize their hot melt coating processes and enhance overall productivity.

Proper maintenance of hot melt coating machines is crucial for enhancing performance and longevity. Regularly scheduled maintenance can lead to significant cost savings and reduced downtimes. According to a report by IndustryWeek, companies can achieve up to a 30% reduction in operating costs through effective equipment maintenance strategies. This includes routine cleaning, lubrication of moving parts, and timely replacement of worn components to prevent unexpected failures.

Additionally, temperature control plays a vital role in the efficiency of hot melt coating processes. Maintaining optimal operating temperatures not only ensures uniform coating applications but also prolongs the lifespan of the machine components. A study by the American Coatings Association found that machines operating within specified temperature ranges could increase production rates by nearly 15%. Implementing best practices in maintenance, such as regularly monitoring machine conditions and adhering to manufacturer-recommended service intervals, can help elevate overall productivity and ensure consistent quality in production.

When working with hot melt coating machines, the material selection process is crucial for maximizing coating efficiency. Choosing the right adhesive or polymer can significantly impact the overall performance of the coating application. High-quality materials that have been specifically designed for hot melt processes tend to offer better adhesion, faster curing times, and improved thermal stability. It’s essential to evaluate the compatibility of the chosen materials with your equipment and desired finish, as not all materials will provide the same results under varying operational conditions.

Additionally, consider the specific application requirements when selecting materials. For instance, factors such as substrate type, environmental conditions, and required durability should guide your decisions. Utilizing materials that excel in these areas can enhance the efficiency of the coating process, reducing waste and downtime due to material failure. Performing thorough testing with different materials can help identify the best options for your unique needs, thus ensuring optimal performance and efficiency in your hot melt coating applications.

| Tip Number | Tip Description | Material Selection Criteria | Expected Efficiency Improvement |

|---|---|---|---|

| 1 | Choose the Right Adhesive | Compatibility with substrate | 10-20% |

| 2 | Optimize Coating Temperature | Heat resistance of materials | 15-25% |

| 3 | Regular Maintenance | Durability of machine components | 5-10% |

| 4 | Control Application Speed | Viscosity of adhesive | 10-15% |

| 5 | Ensure Proper Surface Preparation | Surface energy of substrates | 20-30% |

| 6 | Utilize the Correct Nozzle Type | Flow characteristics of adhesive | 10-20% |

| 7 | Monitor Environmental Conditions | Humidity and temperature | 5-15% |

When working with hot melt coating machines, optimizing machine settings for different coating applications is crucial for achieving peak efficiency. Customizing parameters based on the specific characteristics of the material and desired outcome can greatly enhance the performance of the coating process.

One effective tip is to leverage advanced technology and real-time data analysis to adjust settings. Incorporating machine learning algorithms can facilitate adaptive optimization, enabling machines to automatically modify parameters based on ongoing measurements and environmental conditions. This can lead to improved consistency and quality in the final product.

Additionally, conducting thorough testing and using response surface methodology can help identify the optimal process parameters. By experimenting with variables like temperature, pressure, and flow rate, you can develop a comprehensive understanding of how these factors influence coating outcomes, ultimately allowing for more precise control over the application. Emphasizing these strategies will not only maximize efficiency but also enhance the overall quality of your coating applications.

To maximize efficiency with hot melt coating machines,

it is crucial to emphasize training and team collaboration,

which are fundamental to increasing productivity and ensuring safety in the workplace.

As organizations adopt advanced technologies, equipping staff with the necessary skills and knowledge becomes paramount.

Continuous training programs help employees stay updated on the latest operational techniques and safety protocols,

leading to fewer accidents and higher output quality.

Furthermore, fostering a culture of collaboration enhances communication among team members, enabling them to

share insights and best practices effectively.

By leveraging platforms that facilitate teamwork, such as digital communication tools and collaborative software,

businesses can streamline their processes and create a more cohesive working environment.

This collaborative approach not only boosts the efficiency of hot melt coating operations but also promotes

a safe workplace culture, where employees feel empowered to voice concerns and contribute to operational improvements.