In the world of manufacturing, a Film Coating Machine plays a vital role. This specialized equipment allows for the even application of coatings on various products. Industry expert John Thompson once noted, "Film coating machines are essential for achieving uniformity and quality in coatings."

Film coating machines enhance product performance. They provide protection and enhance aesthetics. However, these machines can be complex and require careful calibration. Many users struggle with settings that can lead to inconsistent results. The ideal film thickness must be achieved for optimal performance, which can be challenging.

Moreover, there are maintenance issues that need addressing. Without proper upkeep, the efficiency of the film coating machine can deteriorate. Regular checks and adjustments are critical to avoid costly downtime. The film coating machine represents both innovation and challenges. Each user must navigate its advantages and pitfalls.

A film coating machine is an essential device used in various industries, primarily for pharmaceuticals, food, and electronics. It applies a thin layer of coating materials onto tablets, granules, or other solid products. This coating enhances the product's appearance, improves stability, and can control the release of active ingredients.

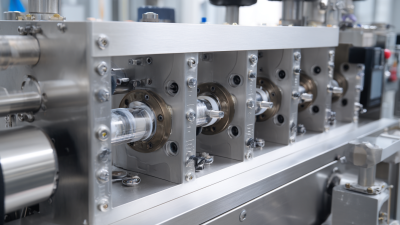

These machines operate through a simple yet intricate process. They generally consist of a pan or drum where the products are placed. A spray nozzle applies the coating solution while the products rotate. As the solution is sprayed, it forms a uniform film over the items. This process requires precision control of temperature and humidity to ensure a successful coating. Even minor adjustments can affect the coating's quality drastically.

However, challenges exist in this process. Achieving a consistent coating may be harder than it seems. Inadequate drying can lead to uneven coatings. This outcome can compromise the product’s effectiveness. Operators must calibrate machine settings with care to avoid these pitfalls. Continuous learning and adjustments in method are necessary for better results.

A film coating machine is essential in pharmaceuticals and food industries. It applies a thin layer of material over tablets and particles. This process improves product stability and aesthetic appeal. The machine's components play a crucial role in its effectiveness.

Key components of a film coating machine include the spray nozzle, drying chamber, and control panel. The spray nozzle atomizes the coating solution. Proper atomization ensures even coverage. The drying chamber removes moisture quickly, optimizing production efficiency. Data from industry reports show that drying efficiency can impact production rates by up to 30%.

Another vital component is the control panel. It manages temperature and airflow during the coating process. Operators must monitor these parameters closely. If not calibrated properly, the final product may exhibit defects. Inefficient equipment operation may lead to excess waste and increased costs. Issues like uneven coating can arise, necessitating further adjustments. Such complexities require continuous improvement and reflection in production practices.

Film coating machines are essential in the pharmaceutical and food industries. These machines apply thin films to the surface of tablets, pellets, or granules. The process enhances product appearance and improves stability.

The operation begins with the preparation of a coating solution. This solution may contain polymers, plasticizers, and colorants. Once ready, it is atomized into tiny droplets. These droplets are sprayed onto the product moving inside the coating drum. The drum rotates gently, allowing an even coat to form. It’s crucial for the solution to be perfectly atomized; otherwise, the coating won't be uniform.

Temperature and airflow play critical roles in the process. Proper conditions ensure that the coating dries efficiently. However, achieving the right balance can be tricky. Many operators make adjustments based on trial and error. Mistakes, such as over-spraying, can lead to uneven coatings. These challenges require constant monitoring. Understanding equipment behavior through experience leads to improved results over time.

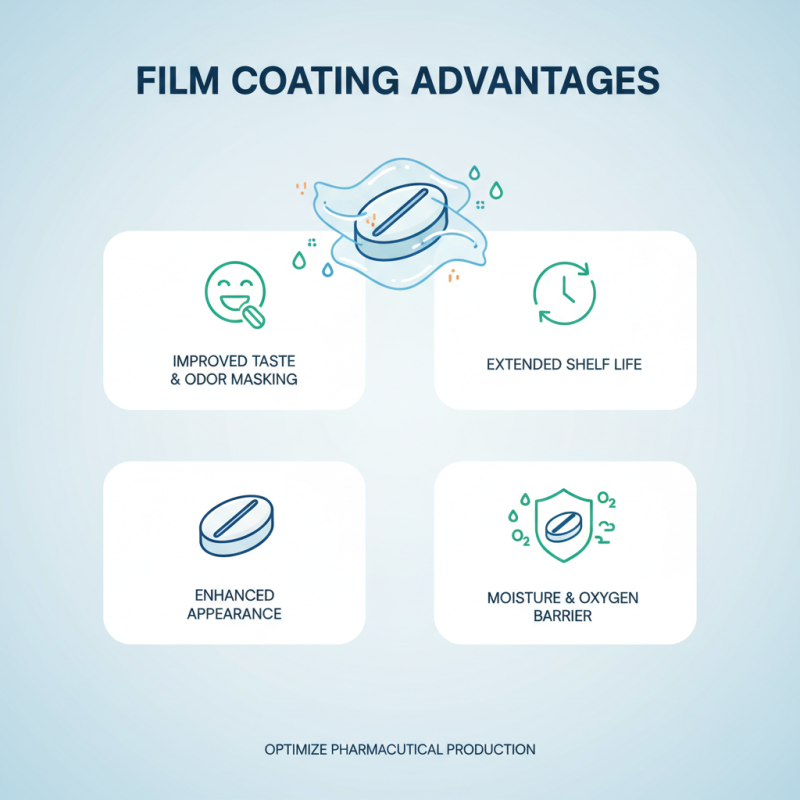

Film coating technology plays a significant role in various industries, enhancing product quality and performance. It is widely used in pharmaceuticals, food, and cosmetics. In pharmaceuticals, for instance, film coating improves drug delivery by masking unpleasant tastes and ensuring stability. According to a recent industry report, the global film coating market is projected to grow to $4.2 billion by 2026, reflecting a compound annual growth rate (CAGR) of 6.2% from 2021.

In the food industry, film coatings serve as protective barriers. They help maintain shelf life and improve the appeal of food products. For instance, edible polymer coatings can preserve moisture in fruits and vegetables, extending their freshness. However, quality control remains crucial. A poorly applied film may lead to uneven coatings, affecting taste and texture.

Tips: Always conduct thorough testing before large-scale production. It’s vital to analyze the coating's impact on product integrity. Regular maintenance of coating machines can prevent defects. Remember, innovation is key, but sometimes, the simplest solutions are the most effective. Focus on continuous improvement to enhance your film coating processes.

Film coating machines offer numerous advantages that enhance the production process. They apply a thin film layer onto tablets or pellets, improving their appearance and functionality. This coating can mask unpleasant tastes and odors, making medication more palatable. Furthermore, it can provide a barrier against moisture and oxygen, extending product shelf life.

Another significant benefit of using these machines is the versatility they offer. They can be adapted for various substances, from pharmaceuticals to food products. However, operating such machines requires careful calibration. An imprecise application can lead to uneven coatings, which affects dosage consistency.

Efficiency is also a key advantage. Film coating machines help streamline production, reducing manual labor and time. But one must consider the initial setup costs and required maintenance. Investing in quality equipment can pay off in the long run, but operators need ongoing training. Balancing these aspects can be challenging, yet it is crucial for successful film coating operations.