The pharmaceutical industry has undergone significant transformations in recent years, with advanced technologies playing a crucial role in enhancing production efficiency. One such technology is the film coating machine, which is pivotal in the formulation process of solid dosage forms. According to a recent report by Research and Markets, the global pharmaceutical film coating market is projected to reach USD 1.3 billion by 2025, growing at a CAGR of 5.2%. This growth is driven by the increasing demand for effective drug delivery systems and the need for better patient compliance, making film coating an essential element in modern pharmaceutical production. By providing benefits such as improved drug stability, controlled release profiles, and aesthetic appeal, film coating machines are significantly impacting production workflows, reducing costs, and enhancing overall product quality. As the pharmaceutical landscape continues to evolve, understanding the role of film coating machines in production efficiency becomes more crucial than ever.

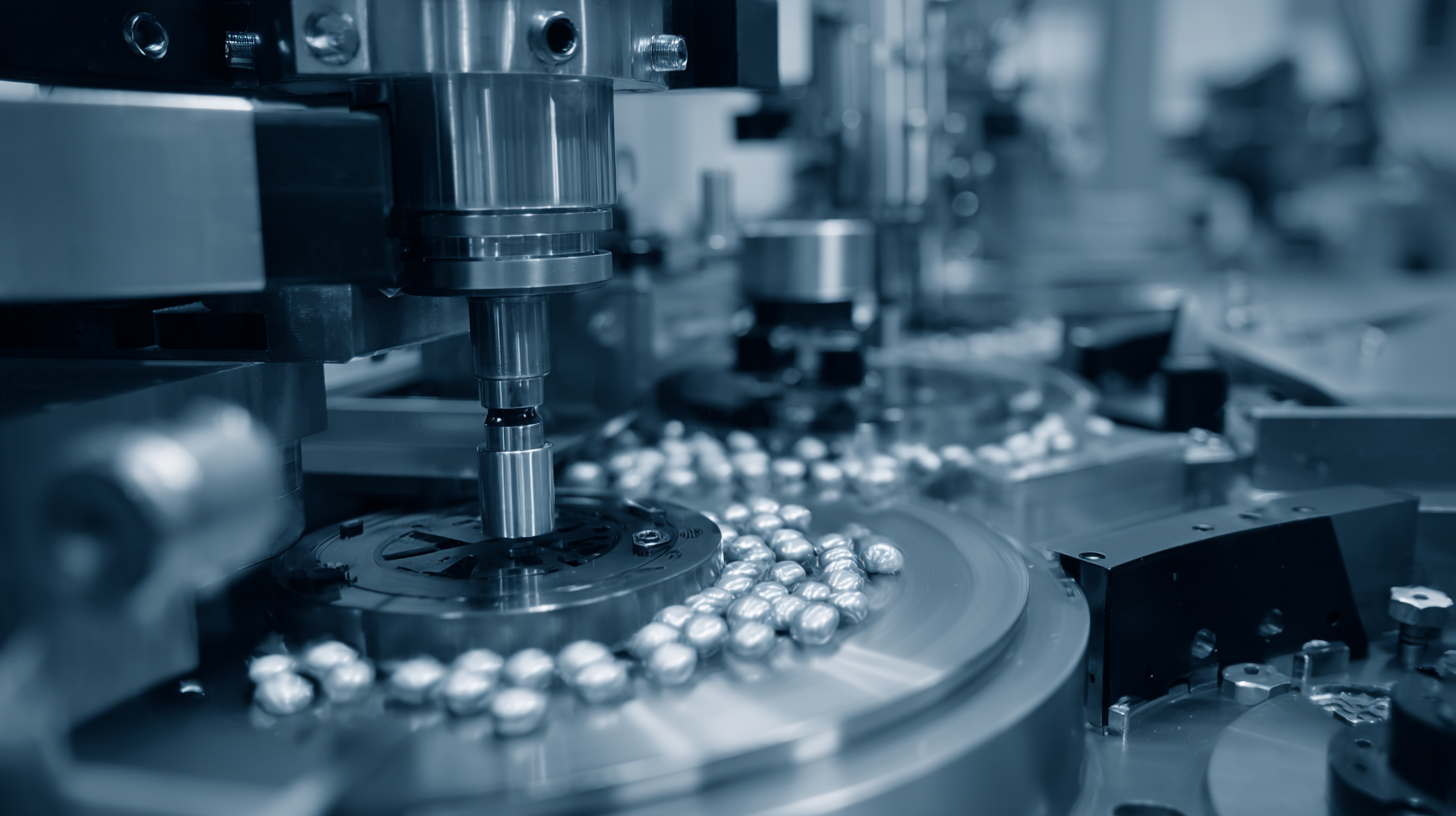

Film coating machines play a critical role in the pharmaceutical industry by enhancing the efficiency and efficacy of drug production. These machines apply a thin layer of polymer-based coating on tablets and pellets, protecting the active ingredients from environmental factors and improving their stability. The film coating process not only enhances the aesthetic appeal of the pharmaceutical products but also allows for controlled release mechanisms, enabling better absorption and effectiveness in the body. Understanding the components and operation of film coating machines is essential for pharmaceutical manufacturers aiming to optimize their production processes.

Film coating machines play a critical role in the pharmaceutical industry by enhancing the efficiency and efficacy of drug production. These machines apply a thin layer of polymer-based coating on tablets and pellets, protecting the active ingredients from environmental factors and improving their stability. The film coating process not only enhances the aesthetic appeal of the pharmaceutical products but also allows for controlled release mechanisms, enabling better absorption and effectiveness in the body. Understanding the components and operation of film coating machines is essential for pharmaceutical manufacturers aiming to optimize their production processes.

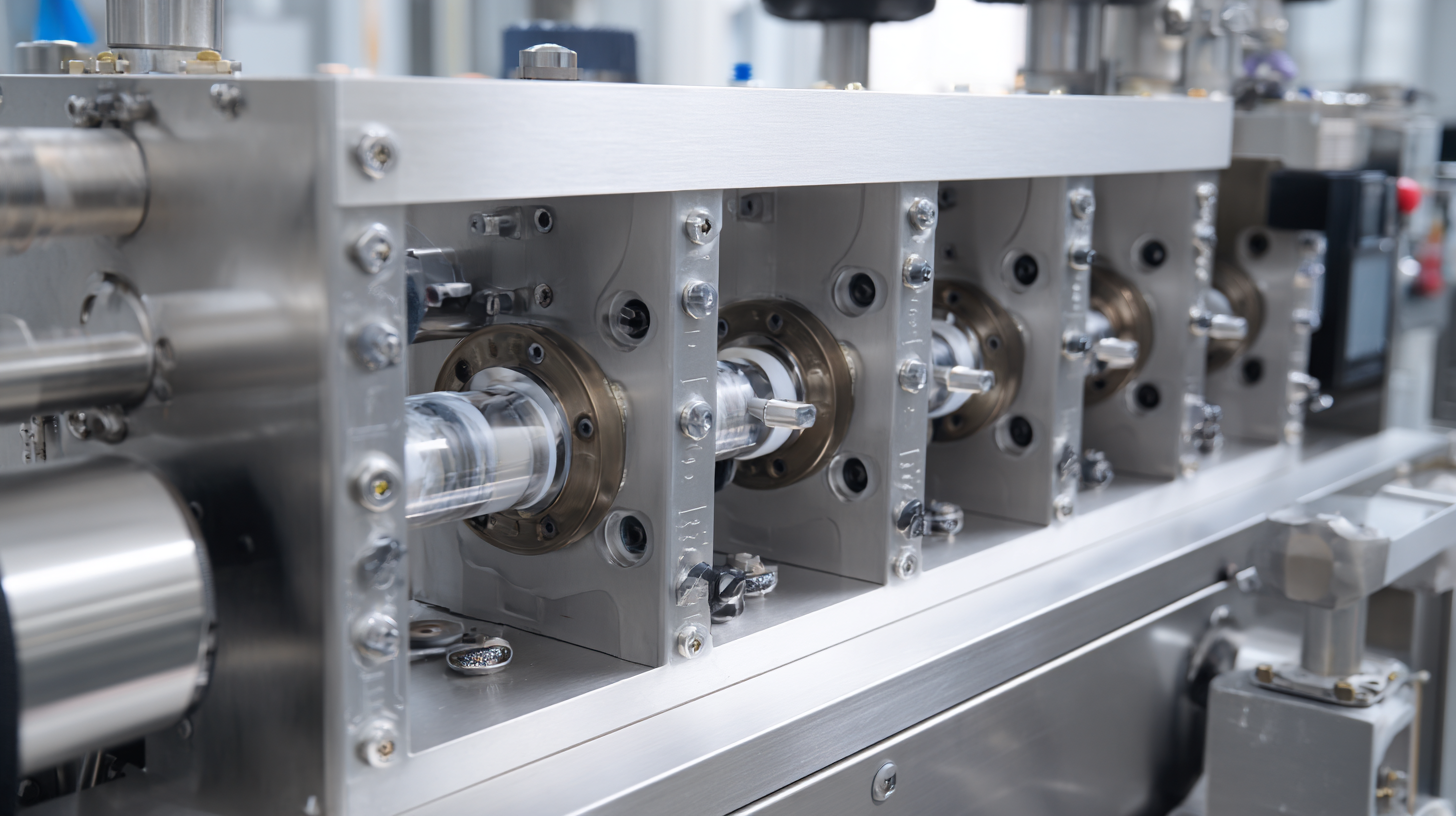

The fundamental principles of film coating machines include the atomization of the coating solution, its uniform application on the substrate, and the controlled drying of the coated layer. The machines utilize advanced technologies, such as spray nozzles and temperature regulation systems, to ensure an even distribution of the coating material. Furthermore, various formulations can be tailored to meet specific requirements, such as taste masking or targeted release. By grasping these basics, pharmaceutical professionals can effectively implement film coating technologies, ultimately leading to improved production efficiency and enhanced product quality in the competitive pharmaceutical market.

Film coating has become a cornerstone of modern pharmaceutical production, significantly enhancing production line efficiency. According to a 2022 market report by Grand View Research, the global film coating market is projected to reach $1.3 billion by 2028, with a compound annual growth rate (CAGR) of 5.5%. The adoption of advanced film coating machines allows for improved process control, which not only minimizes production time but also reduces wastage. In environments where precision is key, these machines can apply coatings uniformly, resulting in consistent product quality that meets regulatory standards.

Further emphasizing these efficiency benefits, a study conducted by the International Journal of Pharmaceutics highlighted that automated film coating processes could reduce overall production time by up to 30%. The integration of high-speed film coating machines allows for continuous operation, thus significantly increasing output without compromising quality. As more pharmaceutical companies leverage these technologies, they can achieve substantial cost savings while boosting their throughput. With the mounting pressure to optimize resources and meet growing market demands, film coating machines represent a vital investment for any production line aiming for enhanced operational efficiency.

The performance of film coating machines plays a crucial role in enhancing the efficiency of pharmaceutical production. Several key factors influence how effectively these machines operate. First, the choice of coating material significantly affects the coating quality and the overall processing time. High-quality polymers with appropriate viscosity can enhance the film formation, leading to a smoother and more uniform finish, which reduces the need for rework and thus streamlines production processes.

Another critical factor is the machine's operational parameters, including airflow, temperature, and spraying duration. Optimal control over these parameters ensures that the coating is evenly applied and adheres well to the substrate. For instance, maintaining the right airflow not only aids in achieving a homogeneous mixture of the coating solution but also prevents issues like sagging or uneven drying of the coating. Regular calibration and maintenance of the equipment are equally important, as they mitigate unexpected downtimes and ensure that the coating processes remain consistent over time, ultimately improving throughput in pharmaceutical manufacturing.

Optimizing film coating processes is crucial for enhancing pharmaceutical production efficiency. The film coating of tablets typically involves a well-coordinated sequence of spraying, mixing, and drying. For optimal coating uniformity, these processes must be harmonized effectively. Implementing a systematic approach can significantly streamline operations, reduce cycle times, and improve product quality.

**Tips: Explore Quality-by-Design Principles:** Integrating quality-by-design (QbD) principles during the formulation of tablets can lead to more consistent and reliable coating outcomes. This approach helps identify critical parameters that affect the coating uniformity and allows for better control of the production process.

Recent advancements in equipment design and process methodologies offer exciting opportunities for optimization. For instance, the introduction of advanced roll-to-roll slot die coating techniques can help achieve specific thicknesses with reduced variability, thereby enhancing the overall production efficiency. Companies are encouraged to leverage these innovations while ensuring rigorous process monitoring and parameter adjustments, which are essential for maintaining high standards in pharmaceutical manufacturing.

**Tips: Emphasize Continuous Improvement:** Establishing a culture of continuous improvement through regular training and performance reviews can empower staff to seek efficiencies in the film coating process. By fostering an environment that encourages innovation, manufacturers can stay ahead in the competitive pharmaceutical landscape.

This chart illustrates the impact of various film coating machine technologies on the production efficiency in pharmaceutical manufacturing.

The future of film coating technology in pharmaceutical production is poised for significant advancements that promise to enhance efficiency markedly. As industries continue to prioritize streamlined operations, the integration of innovative technologies such as ion beam deposition and etching systems is becoming critical. These technologies enable precise control over the coating processes, thereby reducing material waste and ensuring consistent quality in pharmaceutical formulations. This shift towards precision will likely become a defining trend, impacting not only production efficiency but also the overall efficacy of the final products.

Moreover, the development of high-performance membrane materials is set to play a crucial role in the evolution of film coating applications. As manufacturers increasingly focus on improving mechanical strength and simplifying production steps through dry processing techniques, the exploration of advanced materials will be essential. The industry is expected to see accelerated consolidation and innovation, with companies pushing boundaries to create cutting-edge solutions. The movement towards sustainability and efficiency, coupled with advancements in material science, suggests a transformative period for film coating technologies, aligning them closely with the emerging needs of the pharmaceutical sector.