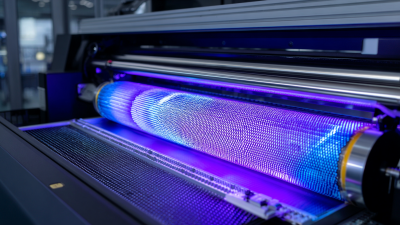

As the world continues to evolve technologically, the PET Coating Machine stands at the forefront of innovation, particularly showcased at the 138th Canton Fair in 2025. This premier event not only highlights advancements in manufacturing machinery but also emphasizes the crucial role of PET coating technology in various industries. With its applications ranging from packaging to electronics, the PET Coating Machine exemplifies the blend of efficiency and precision that modern production demands. The Canton Fair serves as a dynamic platform for manufacturers and suppliers to unveil cutting-edge technologies and foster partnerships that drive sustainability and quality. Attendees will have the unique opportunity to explore the latest developments in PET coating machinery, gain insights from industry leaders, and discuss the future trends that will shape the industry landscape. As we delve into this topic, the significance of PET Coating Machines will become increasingly clear, illustrating their integral part in the broader narrative of industrial progress.

The advanced technologies in PET coating systems unveiled at the 138th Canton Fair 2025 are set to revolutionize the packaging industry, especially in terms of sustainability. As manufacturers increasingly strive to reduce their environmental footprint, innovative PET coatings that enhance recyclability and reduce waste become essential. These cutting-edge solutions not only improve the barrier properties of packaging materials, ensuring product safety and longevity, but also align with global sustainability trends.

By utilizing biodegradable and eco-friendly materials, companies can minimize their reliance on traditional plastics, addressing one of the most pressing challenges in the packaging sector.

By utilizing biodegradable and eco-friendly materials, companies can minimize their reliance on traditional plastics, addressing one of the most pressing challenges in the packaging sector.

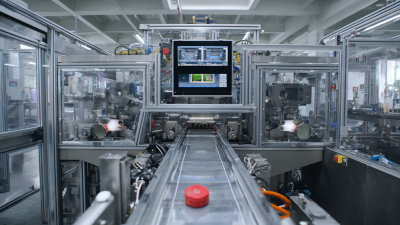

Moreover, the integration of smart technologies within PET coating machines heralds a new era of operational efficiency. Innovations such as automated monitoring systems and data analytics enable producers to optimize resource usage, further driving down energy consumption and emissions during the manufacturing process. These advancements are not merely beneficial for the environment; they also empower companies to meet consumer demands for sustainable packaging solutions.

As the industry moves towards more responsible practices, the impact of these advanced PET coating technologies will resonate throughout the supply chain, fostering a culture of sustainability in packaging that champions both ecological preservation and innovation.

The market for PET coating machines is poised for significant expansion by 2025, fueled by increasing demand across various industries such as packaging, electronics, and automotive. As manufacturers seek innovative solutions to enhance product quality and sustainability, PET coating technology emerges as a vital player in meeting these needs. The trend towards environmentally friendly materials and processes is likely to drive investments in advanced PET coating systems that offer improved performance and eco-efficient production methods.

Moreover, projections indicate a growing adoption of automation and smart technologies in PET coating machines, enhancing productivity and operational efficiency. As companies look to streamline their manufacturing processes, the integration of Industry 4.0 principles will play a crucial role. This shift not only reduces labor costs but also optimizes resource utilization, making it imperative for businesses to invest in modern PET coating solutions that align with future market demands.

The 138th Canton Fair 2025 will undoubtedly showcase these advancements, highlighting the potential for growth and innovation in the PET coating machine sector.

The upcoming 138th Canton Fair in 2025 promises to showcase groundbreaking advancements in PET coating machinery, pivotal for enhancing production efficiency and quality. According to a recent report by Grand View Research, the global market for PET coatings is expected to reach USD 9.3 billion by 2027, growing at a CAGR of 5.3%. This surge is spurred by rising demand in packaging applications, driving manufacturers to innovate and upgrade their machinery to maintain competitive edge.

Innovations in PET coating technology include automation, real-time monitoring, and the integration of artificial intelligence, which collectively boost operational efficiency and minimize material waste. A study conducted by MarketsandMarkets indicates that companies using advanced coating machines can increase productivity by up to 30% while significantly improving the consistency and durability of the coatings applied. At the Canton Fair, industry leaders will present their latest solutions designed to reduce downtime and enhance the precision of coating processes, thereby setting new standards for quality in production lines.

The future of PET coating machine technology is set to be significantly influenced by advances in automation and artificial intelligence (AI). As industries increasingly leverage modern technologies, the integration of automation into PET coating processes is projected to enhance operational efficiency and reduce production costs. According to a recent report from MarketsandMarkets, the global automation market in manufacturing is expected to reach $214 billion by 2025, emphasizing the growing need for automated solutions in various industrial applications, including PET coating.

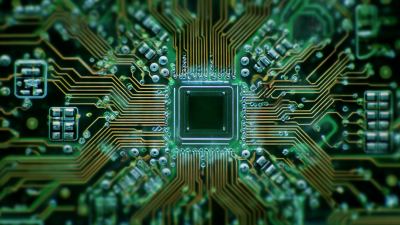

AI is playing a pivotal role in elevating the capabilities of PET coating machines. With the implementation of AI-driven algorithms, manufacturers can optimize coating processes through predictive maintenance, real-time monitoring, and quality control. A study by Statista reveals that the adoption of AI in manufacturing processes could lead to a productivity increase of up to 40% by 2030. As the industry adopts these technologies, the ability to produce high-quality PET coatings with superior performance characteristics will become more prevalent. The combination of automation and AI not only streamlines production but also enhances product durability, making it an essential focus at the upcoming 138th Canton Fair 2025.

| Feature | Description | Benefits | Future Outlook |

|---|---|---|---|

| Automation | Integration of automated processes to enhance efficiency. | Increased production speed and reduced operational costs. | Higher adoption rates expected in the coming years. |

| AI Technology | Utilization of AI for predictive maintenance and process optimization. | Reduced downtime and improved product quality. | Continuous advancements in AI capabilities. |

| Smart Monitoring | Real-time monitoring systems for enhanced oversight. | Quick identification of issues and improved decision-making. | Growing trend towards IoT integration. |

| Eco-efficient Processes | Adoption of sustainable materials and procedures. | Lower environmental impact and compliance with regulations. | Increased demand for green technologies. |

At the upcoming 138th Canton Fair in 2025, the evolution of PET coating technology will be a significant focal point, particularly in terms of industry standards and compliance within China. As the demand for PET coatings increases across various sectors, including packaging and automotive, the imperative for adhering to rigorous industry standards becomes ever more pronounced. The fair will serve as a platform for stakeholders to assess the latest advancements in PET coating machines and their compliance with international safety and quality standards.

Participants will have the opportunity to engage with industry leaders and regulatory bodies to discuss the importance of maintaining high benchmarks for PET coating processes. These discussions will not only address existing compliance measures but also pave the way for future innovations in the technology. By evaluating current practices and ensuring alignment with global standards, the industry can enhance the reliability and safety of PET coatings, ultimately benefitting manufacturers and consumers alike. The Canton Fair is poised to be a crucial event for understanding the trajectory of PET coating technology and its compliance landscape in China.