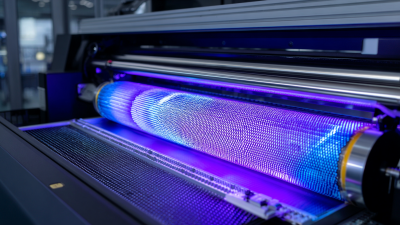

The evolution of UV coating machines is rapidly transforming the global coating industry, presenting an array of innovative solutions that enhance productivity and sustainability. According to a report by Smithers Pira, the UV coating market is projected to grow at a compound annual growth rate (CAGR) of 6.2% from 2020 to 2025, driven by increasing demand for high-quality finishes in various sectors such as packaging, automotive, and electronics. As manufacturers seek to improve operational efficiency and reduce environmental impact, advancements in UV coating technology have become increasingly critical.

With capabilities such as faster curing times, enhanced durability, and a wider range of compatible substrates, the next generation of UV coating machines is set to redefine industry standards. This blog will explore the benefits of these innovations, highlighting how they not only meet market demands but also promote sustainable practices within the coating sector.

With capabilities such as faster curing times, enhanced durability, and a wider range of compatible substrates, the next generation of UV coating machines is set to redefine industry standards. This blog will explore the benefits of these innovations, highlighting how they not only meet market demands but also promote sustainable practices within the coating sector.

The UV coating industry is undergoing a significant transformation driven by emerging technologies that promise to enhance efficiency, sustainability, and versatility. According to a report by Allied Market Research, the global UV coatings market is expected to reach $3.73 billion by 2027, growing at a CAGR of 10.2% from 2020 to 2027. This growth is largely attributed to innovations such as LED UV curing, which not only reduces energy consumption but also improves the quality of coatings by minimizing the risk of yellowing and providing a faster curing time.

One of the key advancements in UV coating machines is the integration of smart technology, enabling real-time monitoring and adjustments to the coating process. For example, the implementation of IoT applications allows manufacturers to collect data on the curing process, optimizing the use of materials and energy. A study by Smithers Pira estimates that incorporating such smart solutions could reduce waste by up to 30%, significantly lowering production costs while increasing environmental responsibility. As these technologies continue to evolve, they pave the way for a more efficient and sustainable future for the global coating industry.

As industries increasingly prioritize sustainability, UV coatings have emerged as a greener solution for manufacturers looking to reduce their environmental footprint. According to a report by Smithers Pira, the global market for UV coatings is expected to reach USD 2.4 billion by 2025, driven by their low VOC emissions and energy-efficient curing processes. Unlike traditional solvent-based coatings, UV coatings cure instantly when exposed to ultraviolet light, significantly decreasing the time and energy required for drying and reducing waste generated during production.

Furthermore, UV coatings are highly durable and provide excellent protection against scratches, chemicals, and UV radiation, which extends the lifespan of finished products. The American Coatings Association notes that advancements in UV technology have led to the development of formulations that contain up to 40% bio-based content, enhancing their environmental appeal. As manufacturers seek to comply with stricter regulations and cater to environmentally conscious consumers, the adoption of innovative UV coatings will play a critical role in shaping a sustainable future for the coating industry.

The global coating industry is experiencing a significant transformation driven by smart automation technologies, particularly through the integration of Artificial Intelligence (AI) and the Internet of Things (IoT) in UV coating processes. According to a report from MarketsandMarkets, the UV coatings market is expected to grow from USD 2.11 billion in 2021 to USD 3.04 billion by 2026, driven by advancements in automation that enhance efficiency and reduce waste. AI algorithms can analyze real-time data from IoT-enabled UV coating machines, optimizing cure times and improving coating consistency while minimizing defects.

For companies looking to leverage these advancements, it’s essential to consider the potential benefits of predictive maintenance. Monitoring machine performance through IoT devices enables proactive maintenance, reducing downtime and maximizing productivity. Furthermore, incorporating AI-driven quality control systems can dramatically enhance product quality by identifying anomalies in the coating process before they escalate into significant issues.

Another crucial tip for businesses is to invest in employee training on AI and IoT technologies. Ensuring that staff are well-versed in these innovations will facilitate smoother transitions and enhance overall operational productivity. As the industry evolves, staying abreast of technological developments and integrating them into daily operations will be vital for maintaining competitiveness in the market.

| Dimension | Current Trend | Future Innovations |

|---|---|---|

| Automation | Increased use of robotic arms | Fully automated UV coating lines |

| AI Integration | Basic AI for process control | Advanced predictive analytics for quality assurance |

| IoT Connectivity | Some machines with IoT sensors | Seamless machine-to-machine communication |

| Energy Efficiency | Standard energy-saving modes | Smart energy management systems |

| Material Development | Traditional coatings dominate | Innovative UV-curable materials |

| User Interface | Basic user interfaces | Intuitive touchscreens with AI assistance |

The global UV coatings market is on the brink of substantial growth, with the

USA leading the charge due to its increasing integration in sectors

such as automotive, electronics, and packaging. This emerging trend highlights a shift towards more

sustainable and efficient coating solutions,

driven by technological innovations and consumer demand for high-performance products. In fact,

the Power Battery UV Coating Market is projected to witness a

remarkable growth trajectory, emphasizing the industry's commitment to advancing coating applications across various fields.

Furthermore, the demand for photoinitiators is expected to surge, with

market projections indicating a rise from USD 1,956.0 million in 2024 to approximately

USD 3,204.4 million by 2031, showcasing a robust compound annual growth rate (CAGR)

of 7.31%. This growth reflects the pivotal role photoinitiators play in the curing process

of UV coatings, further underscoring the innovations that are shaping the future of the coating industry. As businesses

continue to explore advanced coating technologies, the momentum in the UV coatings space

signals a transformative phase for manufacturers and consumers alike.

The UV coating technology industry is poised for significant advancements in the next decade.

According to a report by Smithers Pira, the global market for UV coatings is projected to reach $5.14 billion by 2028, growing at a

CAGR of 8.3% from 2021. This rapid growth is driven by increasing demand for environmentally friendly coatings that enhance

durability and provide superior finish quality. Innovations in UV coating machines, including high-speed curing systems and improved energy efficiency, are expected to meet the

evolving needs of various sectors, including packaging, automotive, and electronics.

One of the key trends shaping the future of UV coating technology is the integration of advanced automation and IoT capabilities.

Research by Mordor Intelligence indicates that the adoption of smart manufacturing processes could increase operational efficiency by up to 30%.

Manufacturers are investing in UV coating machines equipped with real-time monitoring systems that optimize the curing process, leading to energy savings and reduced waste.

Furthermore, advancements in UV LED technology promise to revolutionize the curing process, offering faster curing times and greater flexibility in application, which will ultimately expand

the potential uses of UV coatings across different industries.