In an increasingly interconnected global marketplace, the importance of adhering to trade compliance standards cannot be overstated, especially within the manufacturing sector where technological advancements like the UV Coating Machine are pivotal. According to recent industry reports, the demand for UV coating solutions has surged, with the market projected to grow at a CAGR of 10.3% from 2021 to 2028. This growth underscores the necessity for manufacturers to not only optimize production capabilities but also ensure that their equipment meets stringent certification standards. Ensuring compliance with regulations, such as those stipulated by the International Organization for Standardization (ISO) and other relevant bodies, is crucial for businesses aiming to thrive in this competitive landscape. As we delve into the alternatives for UV Coating Machine certification standards, understanding these requirements will help companies safeguard their operations while maximizing their global trade potential.

As we approach 2025, the landscape of global trade compliance for UV coating machinery is evolving rapidly. This shift is largely driven by the increasing demand for more sustainable and efficient manufacturing practices. Businesses are now expected to adhere to stricter environmental regulations while also ensuring the quality and safety of their products. The integration of advanced technology in UV coating processes not only enhances product performance but also requires compliance with new international standards that dictate energy consumption and emissions.

Moreover, the focus on transparency and traceability will shape the compliance landscape in the coming years. Manufacturers will need to implement robust documentation practices that showcase compliance with regulations across various markets. This means that companies investing in UV coating systems must prioritize adherence to certification standards such as ISO and ASTM, which are becoming pivotal for gaining market access globally. As the industry moves forward, embracing these emerging trends will be essential for those looking to thrive in the competitive landscape of UV coating technology.

The automotive industry's expansion, particularly in emerging markets like China, India, and Brazil, is reshaping the landscape for UV coating machine manufacturers. As the demand for high-performance coatings increases, manufacturers must comply with various key certification standards that ensure safety, sustainability, and quality in their production processes. These standards play a crucial role not only in enhancing product reliability but also in meeting the regulatory expectations of different international markets.

Among the vital certification standards influencing UV coating machine manufacturers are those related to environmental testing and performance assessments. The recent focus on the environmental impact of UV polymer degradation highlights the necessity for manufacturers to adopt rigorous testing protocols. As innovations in UV coatings for automotive and industrial applications continue to emerge, aligning with these certification requirements becomes imperative. This alignment not only fosters competitiveness in a growing market estimated to reach significant valuations, such as the USD 118.5 million projection for the automotive refinish coatings market in Africa by 2025, but also supports sustainable practices within the industry.

Navigating the complexities of global trade compliance in UV coating production requires a deep understanding of certification standards that govern this industry. As manufacturers strive to meet regulatory demands, the need for robust quality management systems becomes evident. This is especially crucial given the projected growth of the photoinitiator market, which is anticipated to reach USD 3204.4 million by 2031, evolving at a CAGR of 7.31%. This growth underscores the importance of adherence to compliance standards, as both production and shipment phases are scrutinized for their alignment with international regulations.

Additionally, innovations such as utilizing fruit waste-mediated nanoparticles for sustainable food packaging illustrate the intersection of compliance with environmental responsibility. This emerging field not only addresses the regulatory challenges but also enhances the sustainability of products. As manufacturers explore new materials and methods, understanding the regulatory frameworks surrounding these innovations is key to ensuring compliance and gaining market acceptance. The journey of navigating these challenges in UV coating production is one that requires a multifaceted approach, balancing compliance, sustainability, and market viability.

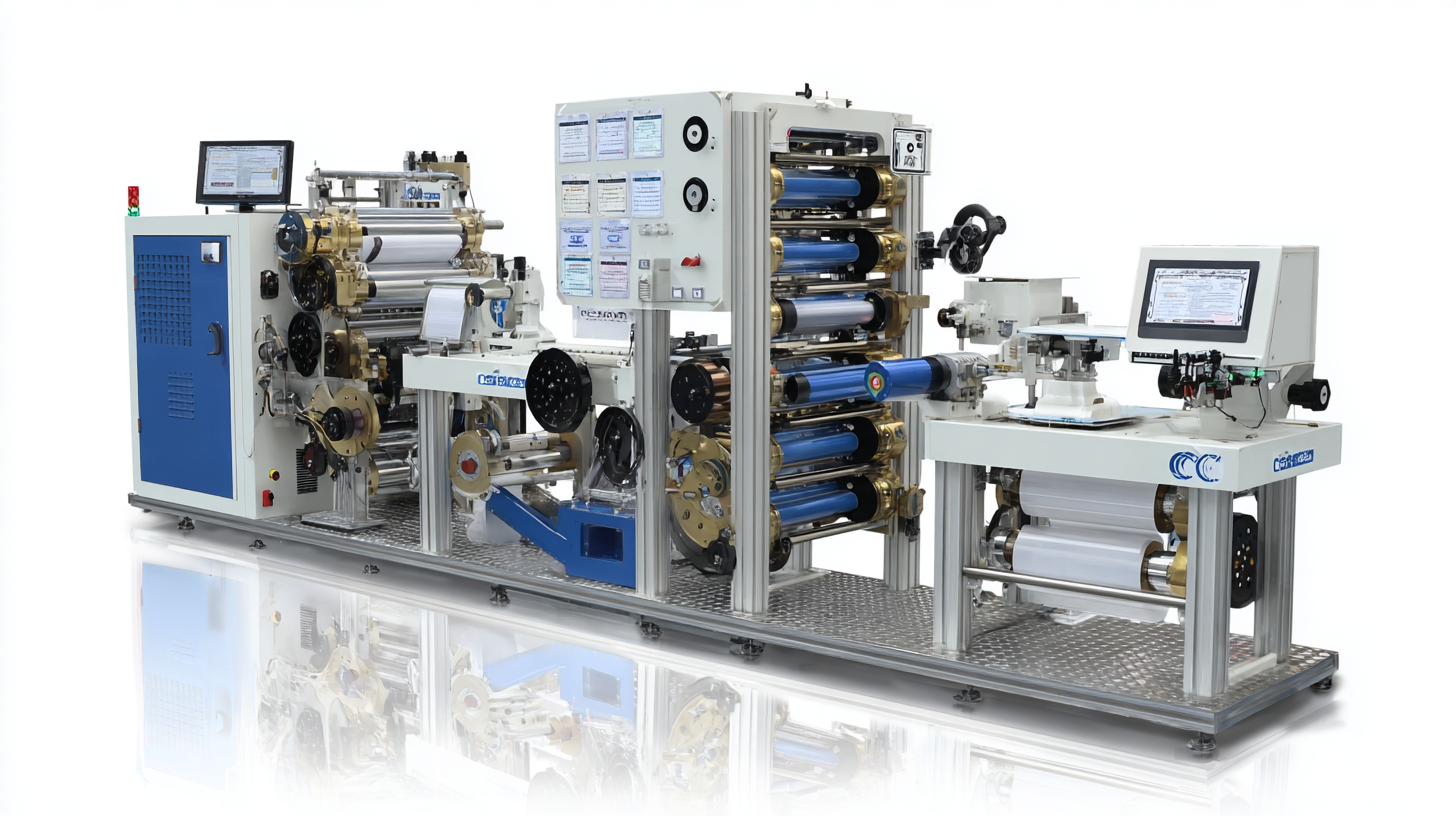

The integration of advanced technology in UV coating machines is pivotal for meeting global trade compliance standards. As industries increasingly focus on sustainability and efficiency, innovative technologies play a critical role in enhancing machine performance and ensuring adherence to stringent regulations. Modern UV coating machines are now equipped with sophisticated monitoring systems and automation features that not only improve the quality of coatings but also streamline compliance processes by providing real-time data and performance metrics.

Furthermore, the introduction of IoT (Internet of Things) capabilities in these machines facilitates remote monitoring and control. This connectivity allows manufacturers to stay updated with regulatory changes and quickly adapt their processes to maintain compliance. By leveraging artificial intelligence and machine learning algorithms, UV coating machines can analyze operational data to optimize workflows and reduce waste, ensuring that they not only meet certification standards but also contribute to a more sustainable production environment. As technology continues to evolve, it will be essential for businesses to embrace these advancements to enhance their compliance strategies and maintain a competitive edge in the global marketplace.

| Certification Standards | Compliance Requirements | Technological Advancements | Benefits of Compliance | Challenges |

|---|---|---|---|---|

| ISO 9001 | Quality Management Systems | Automated Quality Control | Improved Customer Satisfaction | Implementation Costs |

| CE Marking | Safety and Environmental Requirements | Real-time Monitoring Systems | Access to European Markets | Complex Documentation |

| RoHS | Restriction of Hazardous Substances | Lead-free Coating Technologies | Sustainability Goals | Material Sourcing |

| UL Certification | Product Safety Standards | Enhanced Safety Features | Market Credibility | Regular Inspection Fees |

In the rapidly evolving landscape of global trade compliance, future-proofing your UV coating operations has become paramount. According to a report by Smithers Pira, the UV curable coatings market is projected to grow at a CAGR of 8% through 2024, driven by increasing demand for environmentally friendly and energy-efficient solutions. As regulations tighten, staying ahead of compliance standards is not just beneficial but essential for maintaining competitiveness. Adopting best practices in certification can safeguard against potential disruptions from changing policies and consumer expectations.

In the rapidly evolving landscape of global trade compliance, future-proofing your UV coating operations has become paramount. According to a report by Smithers Pira, the UV curable coatings market is projected to grow at a CAGR of 8% through 2024, driven by increasing demand for environmentally friendly and energy-efficient solutions. As regulations tighten, staying ahead of compliance standards is not just beneficial but essential for maintaining competitiveness. Adopting best practices in certification can safeguard against potential disruptions from changing policies and consumer expectations.

Furthermore, the need for rigorous certification standards cannot be overstated. The global UV coating market requires manufacturers to align with ISO 9001 and ISO 14001, ensuring quality management and environmental responsibility. These standards not only enhance product reliability but also cater to a growing consumer base that prioritizes sustainability. By investing in high-quality UV coating machinery that meets these certification benchmarks, businesses can streamline operations while minimizing the risk of costly non-compliance issues as the industry continues to evolve.