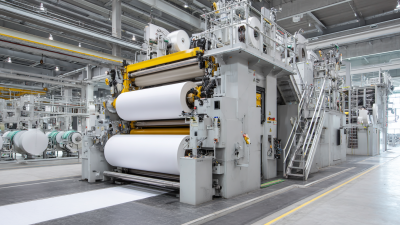

In the rapidly evolving world of manufacturing, the efficiency and effectiveness of production processes are paramount. One of the key players in enhancing production capabilities is the Hot Melt Coating Machine. This specialized equipment plays a crucial role in various industries by providing a reliable method for applying coatings to a wide range of materials. By utilizing advanced technology, Hot Melt Coating Machines streamline production, reduce waste, and improve product quality, ultimately leading to increased profitability for manufacturers.

As companies seek to optimize their production lines, understanding the functionality and benefits of Hot Melt Coating Machines becomes essential. These machines not only ensure a uniform application of coatings but also enable manufacturers to explore diverse formulations and substrates. In addition, the versatility of hot melt technology allows for quicker changeovers and less downtime, making it an attractive option for businesses looking to stay competitive in a fast-paced market.

In this essential guide, we will delve into the various aspects of Hot Melt Coating Machines, exploring their design, operational principles, and the advantages they offer in boosting production efficiency. Whether you are a seasoned industry professional or new to the field, this guide will provide valuable insights on how to leverage this innovative technology for optimal results in your production processes.

Hot melt coating machines play a crucial role in various industries by applying thermoplastic materials onto substrates. This technology involves using heat to melt the adhesive, which is then evenly coated onto surfaces for improved functionality. The unique ability of hot melt coatings to adhere strongly enhances products' durability and performance, making them ideal for applications such as packaging, automotive, and construction. By creating a robust barrier against moisture and other environmental factors, these machines contribute significantly to product longevity.

One of the key applications of hot melt coating machines is in the packaging industry. They are used to create seals and coatings that ensure the integrity of food and pharmaceutical products. The instant bonding capability of hot melt adhesives accelerates production processes, thereby enhancing overall efficiency. Additionally, these machines are employed in manufacturing non-woven fabrics, where hot melt coating can add functional properties like water resistance and breathability. As industries continue to evolve, the versatility of hot melt coating technology offers numerous opportunities for enhancing product performance and reducing production costs.

Hot melt coating machines play a crucial role in enhancing production efficiency across various industries. Understanding the key components and mechanisms behind these machines can significantly optimize their functionality and the resultant output quality. At their core, these machines consist of a melting unit, application system, and curing zone. The melting unit is responsible for heating the polymer until it reaches a fully liquid state. Precise temperature control is essential to ensure the correct viscosity for application, allowing for a uniform and consistent coat.

The application system then distributes the molten material onto the substrate. There are different application methods, such as slot dies or roll coater systems, each suitable for specific needs. Following application, the coating must be cured. This can be achieved through various methods, depending on the material used. Efficient curing ensures that the coating adheres properly and provides the desired protective properties.

Tips: To enhance efficiency when using hot melt coating machines, ensure regular maintenance of all components to avoid downtime. Additionally, monitor temperature settings closely, as fluctuations can lead to inconsistent coating quality. It's also advisable to experiment with different application speeds and patterns to find the optimal setting for your specific production needs.

Hot melt coating is revolutionizing production efficiency across various industries by providing a rapid and effective method for applying coatings. The primary advantage of hot melt coating is its ability to enhance product performance while reducing operational costs. This method utilizes thermoplastic adhesives that are heated to a liquid state, allowing for a smooth and even application on substrates. As the coating cools, it forms a strong bond that improves adhesion and durability, making it an ideal choice for manufacturers looking to optimize their production processes.

One of the key benefits of hot melt coating is its versatility in application. This technology can be used on a wide range of materials, including paper, plastic, and metal, which makes it suitable for different products. Additionally, hot melt coatings often require less energy and time to apply compared to traditional methods, thus increasing overall production speed. By incorporating hot melt coatings into their processes, manufacturers can achieve significant savings in both time and resources.

Tips for maximizing the benefits of hot melt coating include:

Maintenance of hot melt coating machines is crucial for ensuring optimal production efficiency and minimizing downtime. Regular maintenance activities, such as cleaning the heat transfer surfaces and inspecting the melt pumps, can significantly reduce the risk of operational failures. According to a report by the Adhesive and Sealant Council, routine maintenance can improve production efficiency by up to 25% and enhance the longevity of the machinery. Operators should establish a schedule for checking key components, such as hoses and mixers, to prevent contamination and ensure a consistent coating quality.

Troubleshooting is equally important when addressing performance issues in hot melt coating machines. Common problems include inconsistent coating thickness and uneven application, which can stem from issues like improper temperature settings or worn-out components. The same industry report highlights that around 30% of production inefficiencies can be traced back to inadequate troubleshooting practices. Employing a systematic approach to identify and rectify these issues not only improves product quality but also reduces waste, contributing to cost savings. Implementing preventive measures based on collected data can further optimize machine performance and address potential problems before they escalate.

The future of hot melt coating technology is poised to witness remarkable advancements that will significantly enhance production efficiency. As manufacturers increasingly seek sustainable and cost-effective solutions, innovations in material science and process automation will play a critical role. For instance, the development of bio-based hot melt adhesives is gaining traction, driven by environmental concerns and the demand for more sustainable manufacturing practices. These eco-friendly formulations not only reduce reliance on petroleum-based products but also maintain the performance characteristics required for various applications.

Moreover, the integration of smart technologies into hot melt coating machines is another trend that holds promise for the industry. By incorporating data analytics, machine learning, and IoT connectivity, manufacturers can optimize their production processes in real-time. This allows for predictive maintenance, streamlined operations, and reduced downtimes, ultimately enhancing the overall efficiency of production lines. The ability to monitor and adjust parameters dynamically ensures that quality remains consistent, while also minimizing waste and energy consumption. As these technological innovations continue to evolve, they will redefine the capabilities and applications of hot melt coating machines across various sectors.