The industrial landscape is witnessing a significant transformation as innovative coating machine technologies reshape operational efficiency across various sectors. According to the latest market analysis by ResearchAndMarkets, the global coating equipment market is projected to reach approximately $26 billion by 2025, growing at a CAGR of 6.2%. This growth is driven by technological advancements and the increasing demand for high-performance coatings in industries such as automotive, aerospace, and electronics. Advanced coating machines are not only enhancing the quality and durability of products but also streamlining production processes, reducing waste, and minimizing environmental impact. As manufacturers adopt these cutting-edge technologies, the spotlight is on how coating machines are revolutionizing industrial practices, leading to improved productivity, cost savings, and sustainable manufacturing solutions.

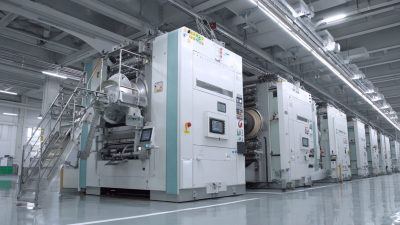

The advancements in coating machine design are pivotal for enhancing productivity across various industrial sectors. Recent developments in high-efficiency coating machines indicate a significant market growth, driven by the increasing demand for precision and speed in manufacturing processes. As industries strive for greater competitiveness, innovations in machine design are focusing on integrating advanced technologies that improve operational efficiency and reduce material waste. These machines are now equipped with automated controls and monitoring systems, allowing for real-time adjustments and optimal performance.

Moreover, the incorporation of smart technologies, such as IoT and AI, into coating machines facilitates predictive maintenance and minimizes downtime. By leveraging data analytics, manufacturers can fine-tune their operations, leading to improved throughput and product quality. As highlighted by the market projections, the coating machine sector is set to undergo a transformation, with designs evolving to meet the nuanced requirements of various applications, ultimately driving enhanced productivity and contributing to the sustainability agenda within the industrial landscape.

| Feature | Description | Efficiency Improvement (%) | Implementation Time (Weeks) |

|---|---|---|---|

| Automated Spray Technology | Utilizes robotics for precise coating application | 30% | 12 |

| Advanced Curing Systems | Incorporates UV/light curing for fast drying | 25% | 10 |

| Energy-efficient Heating | Uses infrared technology to reduce energy consumption | 20% | 8 |

| Smart Control Systems | Integrated sensors for real-time monitoring and adjustments | 35% | 14 |

| Modular Equipment Design | Flexible setup allows for quick reconfiguration | 15% | 6 |

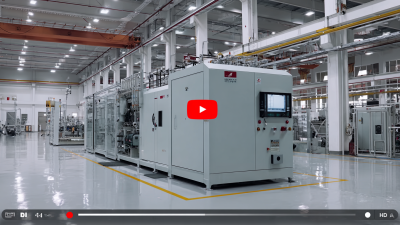

The integration of automation in coating processes

has emerged as a game-changer for the industrial sector, significantly minimizing downtime and boosting productivity. Advanced coating machine technologies are designed to streamline operations, allowing manufacturers to achieve higher output with consistent quality. Automated systems reduce human error, ensuring precise application of coatings.

This not only enhances product durability but also decreases material waste, further contributing to efficiency in production lines.

The integration of automation in coating processes

has emerged as a game-changer for the industrial sector, significantly minimizing downtime and boosting productivity. Advanced coating machine technologies are designed to streamline operations, allowing manufacturers to achieve higher output with consistent quality. Automated systems reduce human error, ensuring precise application of coatings.

This not only enhances product durability but also decreases material waste, further contributing to efficiency in production lines.

Moreover, the adoption of smart technologies, such as IoT sensors and real-time monitoring, facilitates predictive maintenance. By analyzing machine performance data, companies can schedule maintenance during non-peak hours, thereby reducing interruptions in production. This proactive approach to equipment management maximizes uptime, allowing businesses to fulfill orders more reliably and respond swiftly to market demands.

In this rapidly evolving industrial landscape, the combination of automation and innovative coating machine technologies is proving essential for companies seeking to maintain a competitive edge.

The advent of smart technologies has revolutionized the way coating machines operate in industrial settings. Real-time monitoring and control have become essential components, enabling manufacturers to refine their processes with unprecedented precision. By integrating sensors and IoT connectivity, operators can track parameters such as temperature, humidity, and viscosity in real time, ensuring optimal conditions for each coating application. This instant feedback loop not only reduces waste but also enhances product quality, as adjustments can be made on-the-fly to meet specific operational requirements.

Moreover, advanced data analytics plays a crucial role in the ongoing improvement of coating technologies. By leveraging machine learning algorithms, these systems can analyze historical data to predict potential failures or inefficiencies in the coating process. This predictive capability allows for proactive maintenance schedules and helps in minimizing downtime. As a result, industries can achieve higher throughput and greater operational efficiency while maintaining a sustainable approach to resource management, ultimately leading to significant cost savings and increased competitiveness in the market.

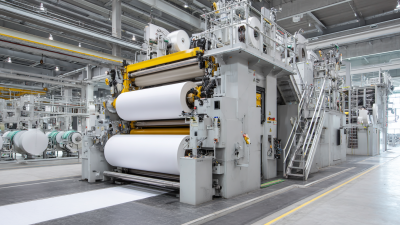

The shift towards sustainable manufacturing has brought eco-friendly coating solutions to the forefront of industrial processes. These innovative coating technologies not only enhance product durability and performance but also minimize environmental impact. By utilizing water-based coatings, plant-based materials, and advanced application techniques, manufacturers are significantly reducing volatile organic compounds (VOCs) emitted during production. This shift aids in the preservation of air quality and supports compliance with stringent environmental regulations.

In addition to regulatory benefits, eco-friendly coating solutions contribute to resource efficiency. Many of these technologies are designed for lower energy consumption and waste reduction, aligning with the broader goal of sustainability. For instance, powder coatings, which contain no solvents and can be recycled, lessen the need for hazardous chemical cleanup. Moreover, advancements in precision application methods ensure that every drop of coating is utilized effectively, reducing excess material usage. As industries continue to innovate, the adoption of these green practices promises not only to boost industrial efficiency but also to pave the way for a more sustainable future.

This chart illustrates the impact of innovative coating technologies on industrial efficiency, specifically examining eco-friendly coating solutions over recent years.

The global epoxy coatings market is projected to grow from $36.53 billion in 2021 to $52.13 billion by 2028, representing a compound annual growth rate (CAGR) of 5.2% during this period. This growth reflects a significant shift towards optimizing coating techniques across various industrial applications. Manufacturers are increasingly focusing on sustainability, which is enhancing market trends. As sustainability becomes integral in the coatings industry, companies are prioritizing formulations that require less energy and reduce environmental impact.

In the world of low-friction coatings, the market is anticipated to reach $4.1 billion by 2033, with an impressive CAGR of 6.5%. The demand for performance optimization in sectors such as automotive, aerospace, energy, and industrial machinery is driving this expansion. The adoption of innovative coating machine technologies is crucial to meet these evolving needs, enabling industries to achieve greater efficiency and functionality in their products.

Tips: When optimizing coating techniques, consider implementing advanced technologies that allow for precise application and reduced waste. Additionally, staying informed about sustainable practices can help companies align with market trends and consumer expectations. Embracing innovation in coating processes can lead to significant competitive advantages in diverse industrial fields.