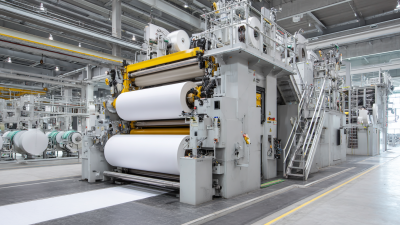

The advent of advanced technologies in sustainable manufacturing has transformed various sectors, particularly in the realm of Coating Machines. These machines, which are pivotal in applying protective and decorative coatings across numerous industrial applications, play a crucial role in enhancing product longevity while promoting environmental sustainability.

According to a report by MarketsandMarkets, the global market for coating machinery is expected to grow to $30 billion by 2025, reflecting a compound annual growth rate (CAGR) of over 4%. This growth is propelled by an increasing demand for eco-friendly products and innovations in coating technologies that minimize waste and energy consumption.

As industries pivot towards sustainability, the integration of smart manufacturing practices with Coating Machines will not only revolutionize production efficiency but also significantly reduce the environmental footprint, further positioning the sector for a more sustainable future.

Advanced coating technologies are playing a pivotal role in the evolution of eco-friendly manufacturing. As industries face increasing pressure to reduce their environmental footprint, innovative coating solutions have proven to be instrumental in promoting sustainability. According to a report by Smithers Pira, the global demand for eco-friendly coatings is projected to reach $85 billion by 2028, driven by advancements in technology and changing consumer expectations. These coatings are not only reducing VOC emissions but also enhancing product longevity and performance, which ultimately contributes to a decrease in material waste.

Advanced coating technologies are playing a pivotal role in the evolution of eco-friendly manufacturing. As industries face increasing pressure to reduce their environmental footprint, innovative coating solutions have proven to be instrumental in promoting sustainability. According to a report by Smithers Pira, the global demand for eco-friendly coatings is projected to reach $85 billion by 2028, driven by advancements in technology and changing consumer expectations. These coatings are not only reducing VOC emissions but also enhancing product longevity and performance, which ultimately contributes to a decrease in material waste.

Moreover, techniques such as nanocoating and water-based coatings are gaining popularity due to their minimal impact on the environment. For example, nanocoatings can provide superior protection against corrosion and wear without the use of harmful solvents. In fact, a study published by Research and Markets indicates that the market for nanocoatings in manufacturing is expected to grow at a CAGR of 27.5% through 2025. As manufacturers adopt these advanced technologies, they can simultaneously improve their operational efficiency and align with global sustainability goals, showcasing a remarkable synergy between innovation and environmental responsibility.

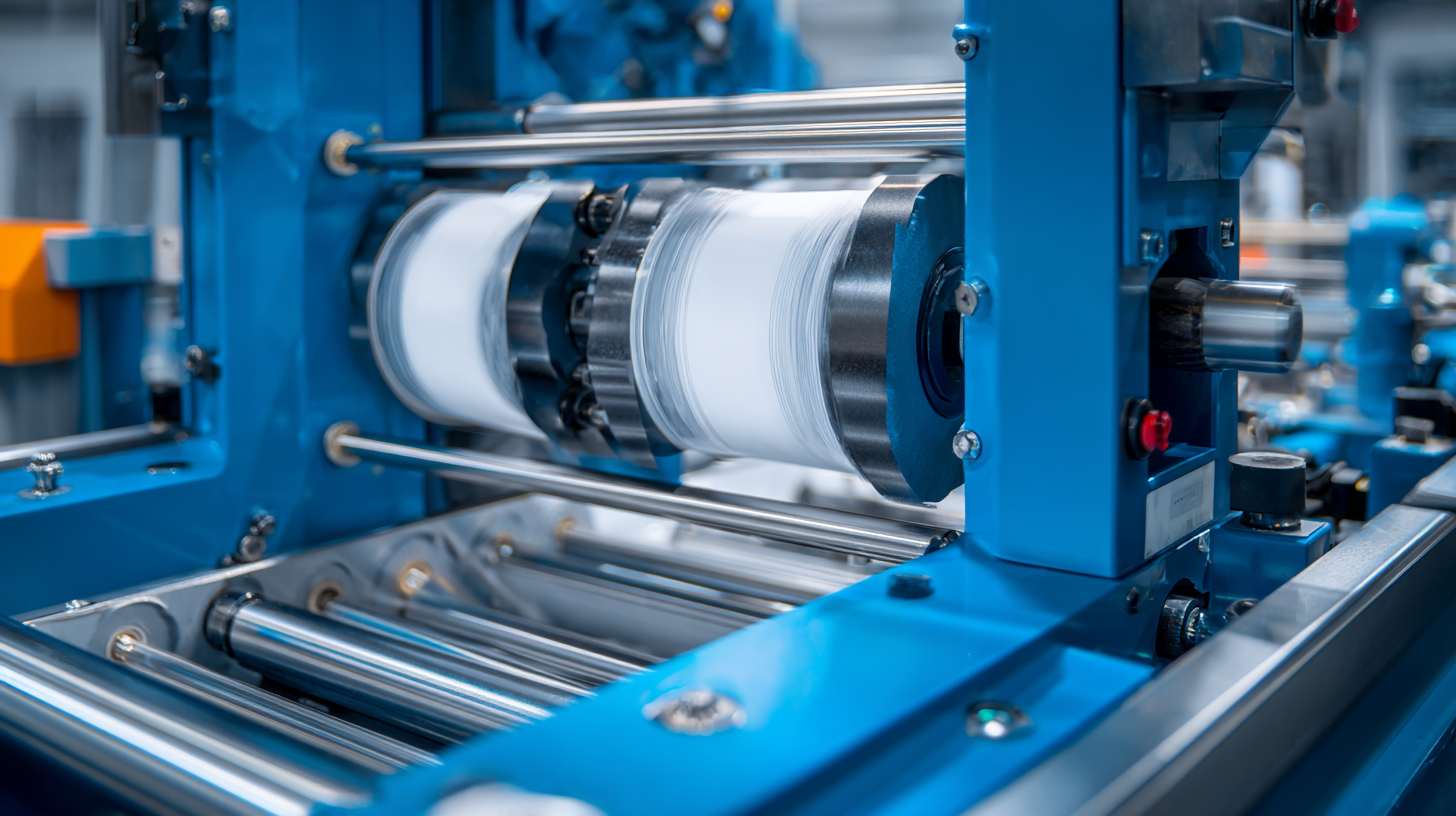

In the realm of sustainable manufacturing, the integration of smart sensors into coating machines represents a transformative leap forward. These advanced sensors facilitate real-time monitoring of the coating process, allowing manufacturers to maintain optimal conditions throughout production. By capturing and analyzing a variety of parameters such as temperature, humidity, and viscosity, smart sensors enable manufacturers to adjust settings on-the-fly, ensuring uniform application of coatings and reducing waste.

Moreover, the use of smart sensors not only enhances the efficiency of coating processes but also contributes significantly to sustainability goals. With precise data collection and analysis, manufacturers can minimize the use of raw materials and energy, effectively lowering their carbon footprint. The ability to predict potential issues before they arise further streamlines the process, reducing downtime and improving overall productivity. As the industry continues to evolve, the marriage of smart sensor technology and coating machines is set to pave the way for more sustainable and efficient manufacturing practices.

The demand for sustainable manufacturing solutions is driving innovation in coating technologies. Innovative materials are at the heart of this transformation. According to a report by Grand View Research, the global eco-friendly coating market was valued at approximately $140 billion in 2021 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2022 to 2030. This growth is fueled by increasing environmental regulations and consumer preference for sustainable products, prompting manufacturers to seek coatings that minimize environmental impact while maintaining high performance.

One of the most promising developments in sustainable coating solutions is the use of bio-based and low-VOC (volatile organic compound) materials. Research from the American Coatings Association indicates that these materials not only reduce harmful emissions but also enhance product durability and longevity. For example, coatings formulated with renewable resources like plant oils can provide similar or superior performance to traditional synthetic coatings, thereby aligning with the principles of sustainable manufacturing. As companies increasingly invest in eco-friendly technologies, the coating industry is poised for a significant transformation, leading to innovative solutions that cater to the needs of both manufacturers and environmentally conscious consumers.

As the manufacturing sector increasingly pivots towards sustainability, minimizing waste in coating applications has become a crucial focus. Efficient coating techniques not only enhance product quality but also significantly reduce material waste and energy consumption. Advanced technologies, such as electrostatic coating and precision spraying, allow manufacturers to apply coatings more uniformly and thinly, thus ensuring optimal use of materials. By fine-tuning application processes, businesses can achieve a higher transfer efficiency, reducing overspray and the need for excessive cleanup.

Moreover, integrating smart technologies can play a pivotal role in waste reduction. Machine learning algorithms can analyze application patterns and adjust parameters in real-time, ensuring that each coating meets the desired specifications without excess. Additionally, employing eco-friendly materials further supports sustainable practices by minimizing harmful emissions and ensuring that byproducts can be recycled or safely decomposed. The shift towards innovative, waste-minimizing coating strategies represents not only a commitment to sustainability but also a pathway to enhanced operational efficiency in manufacturing.

As we look toward the future of coating machines within sustainable manufacturing, the integration of automation and artificial intelligence (AI) stands out as a transformative force. The adoption of cutting-edge technologies in the coating process can significantly enhance efficiency, reduce waste, and optimize resource usage. Industries traditionally reliant on manual processes, such as those in the chemical manufacturing sector, are recognizing the necessity of automation to meet increasing environmental standards and productivity demands. This paradigm shift not only streamlines operations but also aligns with global sustainability goals.

Additionally, the growing trend of AI-driven solutions further contributes to this innovative landscape. Advanced machine learning algorithms can analyze vast datasets, facilitating real-time adjustments in the coating process based on environmental conditions or material specifications. This ability to adapt on-the-fly can lead to more uniform coatings and enhanced product quality, all while minimizing environmental impact. As manufacturers embrace these technologies, the synergy between automation and AI will redefine the capabilities of coating machines, marking a significant leap toward a more sustainable future in manufacturing.