The increasing demand for advanced materials across various industries has propelled the development of innovative technologies, such as the Hydrogel Coating Machine. Hydrogels, due to their unique properties including high water retention and biocompatibility, have become essential in sectors like healthcare, agriculture, and food packaging. According to a recent market report by Research and Markets, the global hydrogel market is expected to reach USD 19.3 billion by 2027, growing at a compound annual growth rate (CAGR) of 6.5%. This growth is largely driven by the rising application of hydrogels in wound care and drug delivery systems, emphasizing the importance of efficient and scalable production methods. As industries seek to harness the benefits of hydrogels, the Hydrogel Coating Machine emerges as a pivotal tool, enabling manufacturers to enhance product performance and meet consumer demands with innovative coating solutions.

Hydrogel coating machines have emerged as transformative tools in both the healthcare sector and the textiles industry, showcasing distinct yet innovative applications in each field. In healthcare, these machines are integral for developing advanced wound dressings and drug delivery systems. The hydrophilic properties of the hydrogels provide an optimal environment for healing, while the precise coating processes ensure uniform application. This can significantly enhance patient care by promoting faster recovery times and reducing infection risks. The technology also allows for customization, enabling the development of coatings that respond to environmental stimuli, further enhancing their therapeutic effects.

Conversely, in the textiles industry, hydrogel coating machines are revolutionizing fabric treatments, offering water-repellent and breathable options for clothing and upholstery. These coatings not only improve the durability of textile products but also add functionalities like moisture management, which benefits athletic wear and outdoor gear. The high adaptability of hydrogel applications in textiles allows manufacturers to cater to specific market demands, focusing on comfort and performance. Overall, while both sectors leverage hydrogel technology for enhanced product performance, the specific requirements and innovations reflect the unique challenges and opportunities within healthcare and textiles.

The innovative applications of hydrogel coating machines are transforming both food packaging and agriculture industries, showcasing distinct performance characteristics. In food packaging, hydrogel coatings provide a barrier to moisture and gases, extending shelf life while maintaining product quality. According to a report by Smithers Pira, the food packaging market is projected to reach $400 billion by 2024, with hydrogel coatings playing a pivotal role in ensuring freshness and sustainability. The use of biodegradable hydrogels aligns with the growing consumer demand for sustainable packaging solutions, reflecting a 12% annual growth in eco-friendly packaging materials.

In agriculture, hydrogel coatings enhance seed performance and water retention in soil, significantly impacting crop yield. A study published in the Journal of Agricultural Science indicated that seeds treated with hydrogel coatings can improve germination rates by up to 30% and reduce irrigation needs by 50%, which is crucial in water-scarce regions. The global agricultural hydrogel market is expected to exceed $2 billion by 2025, driven by the increasing need for efficient water management and crop resilience amidst climate change challenges. These advancements underscore the dual benefits of hydrogel technology across different sectors, promoting efficiency and sustainability.

The cost-benefit analysis of hydrogel coating machines reveals significant insights when contrasting their applications in the electronics and pharmaceutical industries. According to a recent market report by Smithers Pira, the global market for smart coatings, which includes hydrogel coatings, is projected to reach $100 billion by 2026. In the electronics sector, these machines provide enhanced protection against moisture and contaminants, effectively increasing the lifespan of devices. An analysis by Research and Markets shows that integrating hydrogel coatings into electronics can reduce failure rates by up to 30%, translating to substantial savings in warranty costs and repairs.

On the other hand, in the pharmaceutical industry, hydrogel coatings serve a critical role, particularly in drug delivery systems. A study published in the Journal of Controlled Release indicates that hydrogels can improve drug solubility and bioavailability by over 50%. Although the initial investment in hydrogel coating machines may be higher compared to electronics, the long-term benefits, such as improved patient outcomes and reduced healthcare costs, often justify the expense. A detailed evaluation suggests that pharmaceuticals utilizing hydrogel technology could lead to annual savings of approximately $1.2 billion due to enhanced therapeutic effectiveness and reduced hospital visits. This financial perspective showcases the distinct value proposition of hydrogel coatings tailored to each industry’s unique needs.

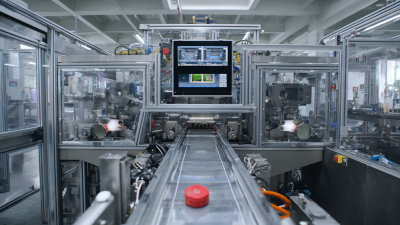

The advent of hydrogel coating machines marks a significant advancement in manufacturing processes across various industries. These machines utilize precise techniques to apply hydrogel coatings, which enhance product durability and functionality. In the medical field, for instance, hydrogel coatings are applied to implants and wound dressings, promoting biocompatibility and moisture retention. The precision of hydrogel application ensures that these products perform optimally, reducing the risk of complications and improving patient outcomes.

In the agriculture sector, the efficiency of hydrogel coating techniques transforms seed coating processes. By creating a protective layer that retains moisture and nutrients, hydrogel-coated seeds enhance germination and growth rates. This innovation not only boosts crop yields but also contributes to sustainable farming practices by reducing water and fertilizer usage. Comparing different hydrogel coating techniques reveals that the choice of application method can significantly impact the efficacy and efficiency of production, highlighting the importance of tailored approaches in manufacturing for diverse applications across industries.

Hydrogel coating machines have gained significant traction across various industries, not only for their innovative applications but also for their promising sustainability attributes. These machines employ hydrogels, which are water-absorbent polymers that can be engineered to be both biodegradable and non-toxic, making them an environmentally friendly option. In the agricultural sector, for instance, hydrogel coatings are used on seeds to enhance moisture retention, reducing the need for frequent irrigation. This not only helps conserve water but also minimizes the ecological impact associated with excessive watering and chemical runoff.

Moreover, in the medical field, hydrogel-coated devices and wound dressings offer biocompatibility while being easy to dispose of without harming the environment. The ability to alter the composition of hydrogels also means that manufacturers can develop products that are tailored to meet specific eco-friendly standards, thus enhancing their sustainability profile. As industries increasingly shift toward greener practices, the adoption of hydrogel coating technology underscores a commitment to eco-friendly solutions that contribute to a healthier planet while maintaining operational efficiency.