Investing in a Sheet and Flat Surface Coating Machine can significantly enhance production efficiency across various industries. According to a recent report by Smithers, the global market for coating machinery is expected to grow at a CAGR of 4.2% from 2021 to 2026, driven by the increasing demand for high-quality surface finishes and the need for improved manufacturing processes. This remarkable growth is largely attributed to advancements in coating technology that allow for faster application, greater consistency, and reduced waste. By automating the coating process, manufacturers can achieve optimal throughput while minimizing labor costs and human error. Furthermore, a well-designed Sheet and Flat Surface Coating Machine is not only instrumental in enhancing product durability but also in meeting stringent industry standards, thereby giving businesses a competitive edge in an increasingly demanding market.

Investing in state-of-the-art sheet and flat surface coating technology can significantly maximize production efficiency across various industries. According to a recent report by MarketsandMarkets, the global market for coating equipment is projected to reach $26.5 billion by 2026, growing at a CAGR of 5.9% from 2021. This growth is primarily driven by the increasing demand for high-quality coatings that enhance product durability and performance. Modern coating machines not only improve the finish quality but also reduce operational downtime, enabling manufacturers to achieve higher throughput rates.

Furthermore, advancements in coating technologies, such as automated application systems and eco-friendly materials, contribute to a more streamlined production process. Data from a study by the American Coatings Association suggests that companies implementing advanced coating methods have reported up to a 30% reduction in material waste and a 20% decrease in labor costs. By upgrading to modern coating solutions, businesses can not only enhance their product quality but also optimize their resource usage, leading to substantial cost savings and improved profitability in the long run.

Furthermore, advancements in coating technologies, such as automated application systems and eco-friendly materials, contribute to a more streamlined production process. Data from a study by the American Coatings Association suggests that companies implementing advanced coating methods have reported up to a 30% reduction in material waste and a 20% decrease in labor costs. By upgrading to modern coating solutions, businesses can not only enhance their product quality but also optimize their resource usage, leading to substantial cost savings and improved profitability in the long run.

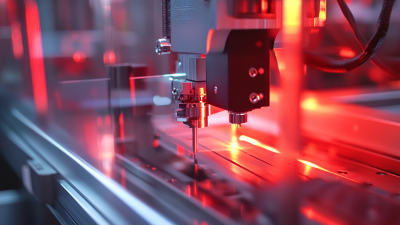

Investing in a sheet and flat surface coating machine can significantly enhance production efficiency by integrating advanced technologies that ensure high-quality coatings. Key features such as uniform coating thickness, rapid curing processes, and the ability to handle various substrate materials stand out as crucial enhancements. For instance, recent studies highlight the optimization of electrodeposition techniques that create durable zinc coatings on multiple surfaces, demonstrating the machine's capability to improve corrosion resistance.

Moreover, innovations in coating materials, like polysaccharide-based antibacterial coatings, are vital for industries facing strict hygiene standards. The application of coatings that not only protect but also combat infection is increasingly essential in healthcare and food sectors. Enhanced surface textures and tailored properties through advanced engineering processes ensure that these machines contribute not only to productivity but also to the functional longevity of coated products. With these features, a sheet and flat surface coating machine can transform production lines, making them more efficient and effective in meeting modern industry demands.

This bar chart illustrates the significant increase in production output after investing in a sheet and flat surface coating machine. The data shows a rise from 200 units per day to 500 units per day, highlighting the productivity enhancement achieved through such technological investment.

Investing in a sheet and flat surface coating machine is not only a strategic choice for enhancing production efficiency but also a financially savvy decision when considering long-term gains. According to a report by MarketsandMarkets, the global market for coating machines is projected to reach USD 12.5 billion by 2025, growing at a Compound Annual Growth Rate (CAGR) of 5.2%. This growth reflects a rising demand across various sectors—such as automotive, electronics, and construction—indicating that manufacturers who invest in advanced coating technology can position themselves competitively in an evolving marketplace.

Conducting a cost-benefit analysis reveals substantial advantages of these investments. A study published by the Association for Manufacturing Technology noted that facilities using modern coating machinery report up to 30% lower operating costs due to improved material efficiency and reduced waste. Furthermore, enhanced precision and speed can lead to shorter production cycles. By minimizing time spent on coating processes, companies can increase output, allowing for better return on investment (ROI). Ultimately, the costs associated with acquiring coating machines are often outweighed by the long-term savings and productivity gains they deliver, reinforcing their value as a key asset for manufacturers aiming for sustained growth.

| Key Factors | Before Investment | After Investment | Difference |

|---|---|---|---|

| Production Speed (units/hour) | 50 | 80 | +30 |

| Labor Cost (per week) | $1200 | $800 | -$400 |

| Material Waste (%) | 10 | 5 | -5 |

| Overall Equipment Effectiveness (OEE) | 65% | 85% | +20% |

| Return on Investment (ROI) | n/a | 150% | n/a |

Integrating sheet and flat surface coating machines into existing production lines can significantly enhance operational efficiency. According to a report by MarketsandMarkets, the global market for coating equipment is expected to grow from $18.1 billion in 2020 to $28.2 billion by 2025, reflecting a compound annual growth rate (CAGR) of 9.2%. This growth highlights the increasing importance of advanced coating technologies in achieving competitive advantages in various industries.

To successfully incorporate coating machines into your production setup, it's essential to conduct a thorough assessment of your current processes. This includes identifying bottlenecks that may hinder productivity and determining how a coating machine could streamline these operations. Data from the National Association of Manufacturers reveals that organizations that adopt automated solutions can improve their production rates by up to 30%. Additionally, investing in training and maintenance for your staff will ensure optimal operation of new machinery, maximizing its potential for transforming your production efficiency.

Maintaining a sheet and flat surface coating machine is crucial for ensuring its efficiency and longevity. Regular maintenance practices not only enhance the machine's performance but also prevent unexpected downtimes that can disrupt production schedules. Key maintenance tasks include routine inspections, which help identify wear and tear before they escalate into significant issues. Daily checks on critical components such as spray nozzles, pumps, and hoses can prevent clogs and ensure an even coating application.