The field of research and development is rapidly evolving, with the integration of advanced technologies playing a pivotal role in streamlining processes and enhancing outcomes. Among these innovations, the Laboratory Coating Machine stands out as a transformative tool that significantly impacts various industries, including pharmaceuticals, electronics, and materials science.

According to a recent industry report, the global laboratory equipment market is projected to grow at a CAGR of 6.5%, reaching approximately $50 billion by 2025, driven by the increasing demand for precise and efficient coating solutions.

The Laboratory Coating Machine not only facilitates the application of uniform coatings but also optimizes production efficiency and enhances reproducibility in experimental setups. As research institutions and companies prioritize innovation, understanding and leveraging the capabilities of these machines will be crucial to unlocking new potentials and accelerating the development of cutting-edge products.

Laboratory coating machines play a crucial role in modern research and development, where precision and efficiency are paramount. These advanced machines are essential for the production of uniform coatings on substrates, such as polymers, metals, and ceramics. According to a recent market analysis by Research and Markets, the global laboratory coating equipment market is projected to reach approximately $4.2 billion by 2025, growing at a CAGR of 5.7%. This growth highlights the increasing reliance on sophisticated coating technologies across various sectors, including pharmaceuticals, electronics, and materials science.

The importance of laboratory coating machines is particularly evident in their application within the pharmaceutical industry, where the development of drug delivery systems requires meticulous coating processes. Coatings can enhance the bioavailability and stability of active pharmaceutical ingredients, enabling more effective treatments. Furthermore, data from a study published in the Journal of Pharmaceutical Sciences indicated that optimized coating processes can reduce production costs by up to 20%, underscoring the economic benefits of these technologies. As R&D continues to innovate, the role of laboratory coating machines will be integral in driving advancements and ensuring product quality across various fields.

This chart illustrates the impact of laboratory coating machines on various dimensions in the research and development landscape. Each dimension is rated on a scale from 0 to 100, highlighting their effectiveness in enhancing efficiency, precision, cost-effectiveness, flexibility, and scale-up potential.

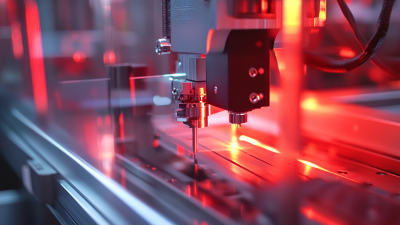

The development of advanced coating technologies has revolutionized laboratory environments by enhancing research capabilities across various fields. Modern laboratory coating machines boast key features that streamline processes and improve precision. For instance, innovations such as automated application systems ensure consistent layer thickness and uniformity, which are crucial for experiments requiring meticulous conditions. These machines often incorporate real-time monitoring systems, enabling researchers to adjust parameters on-the-fly, leading to optimized results.

Tip: When selecting a coating machine, prioritize those with user-friendly interfaces and customizable settings to enhance your workflow efficiency.

Additionally, many advanced coating technologies offer compatibility with a wide range of substrates and materials, making them versatile tools in the lab. Features such as vacuum coating and multi-layer capabilities allow researchers to explore new methodologies and enhance material properties effectively. Moreover, energy-efficient designs contribute to reducing operational costs and environmental impact.

Tip: Regular maintenance and calibration of your coating equipment can significantly prolong its lifespan and ensure consistent performance.

With these essential features and tips, researchers are better equipped to leverage laboratory coating machines for innovative projects that push the boundaries of modern science and technology.

Laboratory coating machines have become essential tools in various research fields, significantly enhancing the capabilities of scientists and engineers. In materials science, these machines are used to create uniform coatings on substrates, which is crucial for studying the properties of new materials. For instance, researchers can apply thin films of polymers or metals to explore their conductive, optical, or protective qualities, paving the way for innovations in electronics and nanotechnology.

In the field of pharmaceuticals, coating machines play a pivotal role in developing drug formulations. By applying coatings to tablets, they can control the release of active ingredients in the human body, thereby improving the efficacy and safety of medications. Additionally, in biology and chemistry, these machines are invaluable for creating samples for microscopy or other analytical techniques, allowing scientists to observe the behavior of cells and molecules under various conditions. The versatility of laboratory coating machines thus underscores their importance across a range of research domains, facilitating breakthroughs in both fundamental and applied sciences.

In today’s fast-paced research and development landscape, laboratory coating machines have emerged as vital tools that enhance both efficiency and precision in experimental processes.

According to a recent report by MarketsandMarkets, the global laboratory equipment market is projected to grow from USD 43 billion in 2021 to USD 66 billion by 2026, indicating a significant saturation of advanced technologies, including specialized coating equipment. These machines facilitate uniform application of coatings, which is crucial for achieving consistent results in experiments, particularly in fields like pharmaceuticals and materials science.

Furthermore, the integration of advanced automation in coating machines has been shown to reduce processing times by up to 30%, enabling researchers to focus on more critical aspects of their work. A study by Frost & Sullivan highlights that the implementation of automated coating processes can improve precision by up to 25%, thereby minimizing variability in research outcomes. This level of precision is essential for the reproducibility of experiments and the reliability of results, ultimately driving innovation and efficiency in research endeavors. As laboratories increasingly seek cutting-edge equipment, the role of coating machines in streamlining research workflows cannot be overstated.

The landscape of laboratory coating machines is evolving rapidly, driven by advancements in technology and the need for precision in research and development. According to a recent market analysis by Grand View Research, the global laboratory coating equipment market is expected to reach USD 1.5 billion by 2025, with a compound annual growth rate (CAGR) of 6.5%. This growth is largely attributed to the increasing demand for thin film coatings in various applications, including pharmaceuticals, electronics, and materials science. As research requirements become more sophisticated, manufacturers are focusing on innovations that enhance the efficiency, accuracy, and versatility of coating processes.

Future trends in laboratory coating machine innovations include the integration of automated systems, real-time monitoring capabilities, and advanced material compatibility. Research published by the Coating Society indicates that automating the coating process can reduce human error by up to 30%, leading to more consistent and reliable results. Furthermore, the development of eco-friendly coatings and the use of nanotechnology in coating formulations are on the rise, reflecting the industry's commitment to sustainability and enhanced performance. These innovations not only fulfill the needs of modern laboratories but also pave the way for groundbreaking discoveries in various fields, demonstrating the critical role of coating technology in the future of research and development.

| Dimension | Current Trends | Future Innovations | Potential Applications |

|---|---|---|---|

| Coating Materials | Polymers, Nanomaterials | Smart Coatings, Biodegradable Materials | Medical Devices, Electronics |

| Application Techniques | Spraying, Dip Coating | Electrospinning, 3D Printing | Advanced Research, Protective Coatings |

| Process Automation | Partial Automation | Fully Automated Systems | High-Throughput Screening, Customizable Solutions |

| Sustainability | Energy Efficiency Focus | Waste Reduction Technologies | Environmentally Friendly Products |