In an era where energy storage solutions are paramount to advancing technology and sustainability, the demand for efficient production methods in the battery industry continues to grow. Among the critical components in battery manufacturing, lithium battery coating machines have emerged as a vital technology in enhancing production efficiency and quality. These machines play a significant role in applying cathode materials uniformly onto battery substrates, ensuring optimal performance and longevity of lithium-ion batteries.

As we look ahead to 2025, the landscape of battery production is evolving, with innovations in lithium battery coating machines paving the way for increased output and reduced operational costs. With manufacturers striving to meet the escalating demand for electric vehicles and renewable energy storage systems, investing in advanced coating technologies will be essential. This not only supports the drive for cleaner energy solutions but also positions companies to remain competitive in a rapidly changing market.

In this paper, we will explore the top lithium battery coating machines that are expected to revolutionize production processes in 2025. By examining their features and technological advancements, we aim to provide insights into how these machines can significantly enhance production capabilities and contribute to the growth of the lithium battery sector in the coming years.

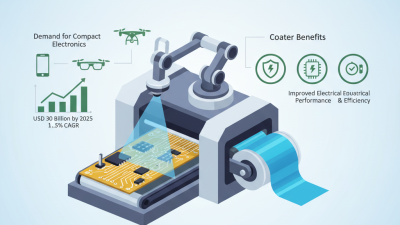

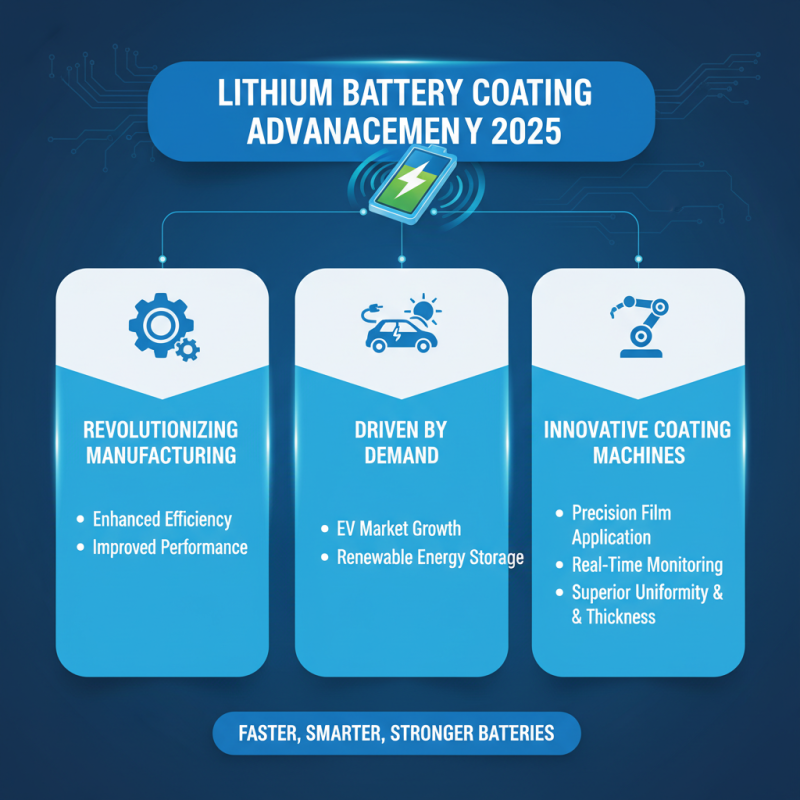

The advancements in lithium battery coating technology for 2025 are set to revolutionize the manufacturing landscape, enhancing both efficiency and performance. As the demand for lithium batteries surges, driven by the growing electric vehicle market and renewable energy storage systems, innovative coating machines are being developed to meet this challenge. These new machines utilize cutting-edge techniques such as precision film application and real-time monitoring systems, ensuring that the coating process is not only faster but also achieves superior uniformity and thickness across battery components.

Moreover, advancements in materials science are enabling the integration of advanced coatings that improve the batteries' thermal stability and lifespan. Techniques like vacuum coating and electrostatic spray are being refined, allowing for better adhesion and reduced waste during production. As manufacturers strive for greater sustainability, these next-generation coating machines are also designed to minimize energy consumption and emissions, aligning with global initiatives to reduce the environmental impact of battery production. The synergy of these technological advancements promises to propel the industry forward, making 2025 a pivotal year for lithium battery manufacturing.

As the demand for lithium batteries surges, particularly in electrification and renewable energy sectors, the efficiency of battery production has become paramount. High-performance battery coating machines are critical to scaling up production capabilities while maintaining quality. According to a report by Research and Markets, the global market for battery manufacturing equipment is expected to reach USD 13 billion by 2025, highlighting the push for advanced technology in this field.

One of the key features of high-performance battery coating machines is their ability to achieve uniformity in coating thickness. A coating thickness variability of less than ±5% is crucial for ensuring consistent battery performance, as fluctuations can lead to reduced energy density and overall efficiency. Additionally, the integration of automation and artificial intelligence in these machines enhances production speed and reduces human error. Data from a recent study by Grand View Research indicates that automated battery production could potentially increase output capacity by up to 40%, which is vital for meeting the rising global battery demands.

Moreover, energy efficiency and waste reduction are becoming increasingly important in battery manufacturing. The adoption of eco-friendly coating materials and solvent recovery systems can decrease environmental impact while optimizing operational costs. Reports suggest that implementing such innovative solutions could cut production waste by as much as 20%, making high-performance battery coating machines not just a technological upgrade but also a strategic investment for manufacturers aiming to thrive in a competitive market.

As the demand for lithium batteries continues to surge, manufacturers are striving to enhance their production processes, particularly in the area of coating technologies. Leading manufacturers in this sector are focused on innovating and refining coating solutions that maximize efficiency and precision. These advancements not only improve the overall performance of lithium batteries but also contribute to sustainability by optimizing material usage and reducing waste.

The top manufacturers in lithium battery coating solutions are investing heavily in research and development to create cutting-edge machines that integrate automation, advanced materials, and real-time monitoring systems. This enables producers to achieve consistent quality and high throughput, essential for meeting the growing market needs. Furthermore, collaborations between industry leaders and research institutions are fostering innovative approaches, ensuring that these manufacturers remain at the forefront of battery technology advancements. The competitive landscape continues to evolve as these companies strive to set new benchmarks in production efficiency, ultimately driving the industry toward a more sustainable energy future.

The demand for lithium battery production equipment is poised for significant growth in 2025, driven by the accelerating shift towards renewable energy and electric vehicles. As industries strive to meet sustainability goals, the production of high-performance lithium batteries has become a critical focus. The need for efficient, reliable, and advanced coating machines is rapidly increasing, as these technologies play a vital role in enhancing battery performance and longevity.

Market trends indicate that manufacturers are investing heavily in innovative coating solutions, which not only optimize the battery's energy density but also improve its overall safety profile. As lithium-ion batteries become indispensable in various applications, ranging from consumer electronics to large-scale energy storage systems, the demand for state-of-the-art production equipment is expected to soar. This evolving landscape highlights the importance of continuous research and development in coating technology, ensuring that production lines can keep pace with the burgeoning market needs of the lithium battery sector.

| Machine Type | Production Capacity (units/hour) | Coating Thickness (µm) | Energy Consumption (kWh) | Price Range (USD) |

|---|---|---|---|---|

| Roll-to-Roll Coater | 80 | 10-30 | 15 | 50,000 - 70,000 |

| Slot Die Coater | 60 | 5-20 | 12 | 40,000 - 60,000 |

| Spray Coater | 50 | 1-15 | 10 | 30,000 - 50,000 |

| Doctor Blade Coater | 40 | 10-60 | 20 | 55,000 - 75,000 |

The efficiency and longevity of lithium batteries are significantly influenced by the quality of the coating applied during manufacturing. Coating machines play a crucial role in ensuring a uniform and precise application of materials that enhance the performance of battery cells. A well-designed coating process contributes to better ionic conductivity, which is essential for optimal charge and discharge cycles. By leveraging advanced technology, these machines can produce high-quality coatings that minimize defects, ultimately leading to batteries that last longer and provide greater energy density.

Moreover, the impact of coating on lithium battery longevity cannot be overstated. As the demand for high-performance batteries increases, the need for effective surface treatments becomes paramount. Coating machines equipped with innovative features can ensure that the active materials within batteries are effectively protected from environmental factors, which can lead to degradation over time. Additionally, improved coatings can facilitate better thermal management, preventing overheating and extending the lifespan of batteries, particularly in demanding applications such as electric vehicles and renewable energy systems. As manufacturers look to boost production in 2025, investing in top-tier coating technology will be essential for meeting both performance and reliability standards.