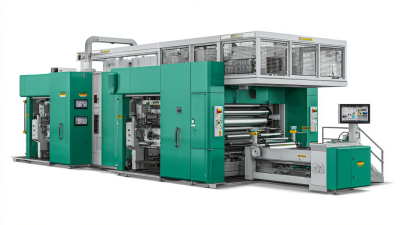

In the fast-evolving landscape of manufacturing, the efficiency of production processes is paramount, particularly in industries utilizing advanced technologies such as the Slot Die Coating Machine. According to a recent report by Smithers Pira, the global market for coating machines is projected to reach $7.8 billion by 2025, highlighting a significant demand for high-precision and cost-effective coating solutions.

Slot die coating technology stands out due to its ability to deliver uniform coating thickness and reduce material waste, ensuring optimal use of resources. As manufacturers seek to enhance their operational efficiency and sustainability, implementing strategic practices tailored for Slot Die Coating Machines becomes essential. This blog will provide a comprehensive checklist to maximize the efficiency of these advanced machines, aiding businesses in staying competitive in a rapidly changing market.

Slot die coating technology is a versatile and efficient method used in various industries for applying uniform thin films on substrates. At its core, the technology employs a precision die to deliver a continuous film of liquid material onto a moving surface. This results in a consistent thickness, which is crucial in applications such as semiconductor manufacturing, solar panel production, and medical device fabrication. Understanding the critical components of slot die coating, including fluid dynamics, die geometry, and operating parameters, is essential for achieving optimal coating results.

One of the fundamental principles behind slot die coating is the interaction between the coating material's viscosity and the speed of the substrate. Adjusting these parameters allows operators to fine-tune the film thickness and uniformity. Additionally, maintaining appropriate flow rates and temperature control can significantly enhance the performance of the coating machine. By mastering these fundamentals, manufacturers can significantly improve production efficiency, reduce waste, and ensure high-quality results in their coating processes. Emphasizing proper setup and regular maintenance of the slot die coating machine is key to maximizing its effectiveness and longevity.

| Strategy | Key Benefits | Implementation Steps | Estimated Efficiency Improvement |

|---|---|---|---|

| Optimize Die Design | Improved layer uniformity and reduced waste | Analyze current designs, adjust flow paths, and use simulation tools | 20-30% |

| Control Viscosities Precisely | Consistent coating thickness and reduced defects | Implement online viscosity measurement and adjustment systems | 15-25% |

| Enhance Temperature Control | Optimal material behavior and improved adhesion | Install advanced heating/cooling systems around the die | 10-20% |

| Automate Process Monitoring | Reduced human error and faster response to issues | Integrate sensors and real-time data analytics | 20-40% |

| Train Operators Effectively | Higher skill levels lead to better machine utilization | Develop comprehensive training programs and hands-on sessions | 15-30% |

When comparing traditional coating methods with slot die coating, several key points emerge that highlight the advantages of slot die technology. One significant difference is the uniformity of the coating application. Slot die coating machines provide a consistent film thickness, minimizing the risk of defects often seen in traditional methods. This uniformity results in higher quality products with less waste, making it a cost-effective solution for manufacturers.

When comparing traditional coating methods with slot die coating, several key points emerge that highlight the advantages of slot die technology. One significant difference is the uniformity of the coating application. Slot die coating machines provide a consistent film thickness, minimizing the risk of defects often seen in traditional methods. This uniformity results in higher quality products with less waste, making it a cost-effective solution for manufacturers.

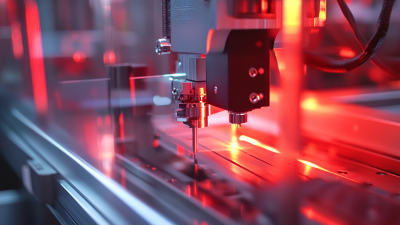

Another crucial aspect is the precision and controllability of the slot die coating process. Unlike traditional techniques, which can lead to variability in how materials are applied, slot die systems allow for fine adjustments in coating parameters. This feature enables manufacturers to optimize their production lines effectively.

Tip: To maximize efficiency, operators should regularly calibrate their slot die systems to ensure precise settings. Furthermore, investing in training for staff can lead to a better understanding of the technology and contribute to smoother operations. Adopting data monitoring tools can also enhance decision-making processes, allowing for quicker adjustments and increased production throughput.

In the fast-evolving landscape of manufacturing,

the efficiency of slot die coating machines can significantly impact production outcomes. Focusing on speed, accuracy, and waste reduction are critical for maximizing these machines' performance. Speed is crucial; manufacturers need to optimize their processes to meet increasing market demands without compromising on quality. By analyzing cycle times and enhancing operational workflows, facilities can reduce downtime and bolster throughput, ultimately leading to higher productivity levels.

Accuracy in coating application is equally important, as it directly affects the final product's quality and the amount of material waste generated. Implementing precise calibration techniques and real-time monitoring systems can ensure consistent application thickness, reducing the need for rework and minimizing waste. Furthermore, investing in advanced technologies can aid in identifying inefficiencies and areas for improvement. As manufacturers strive for sustainability, the reduction of waste not only cuts costs but also aligns with global efforts toward eco-friendly practices. By focusing on these key areas, businesses can achieve a significant competitive advantage in a rapidly growing sector.

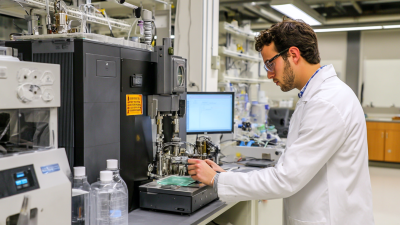

When considering the efficiency of slot die coating machines, understanding material compatibility is essential. Different substrates, such as plastics, metals, and glass, each require specific coating formulations to achieve optimal adhesion and performance. For instance, a polyimide substrate may need a specialized adhesive to ensure that the coating bonds properly at various temperatures, preventing delamination during processing. Attention to the substrate's surface energy and texture can lead to better coating outcomes, reducing waste and enhancing productivity.

In addition to substrate compatibility, the formulation of the coating itself plays a critical role. Whether using water-based, solvent-based, or UV-curable coatings, each option presents unique challenges and advantages in the coating process. For example, solvent-based coatings typically offer better flow and leveling properties, while water-based formulations are more environmentally friendly but may require longer drying times. Therefore, selecting the right combination of substrate and coating formulation is vital for maximizing the efficiency of slot die coating operations, ensuring high-quality finishes and reduced operational costs.

This chart illustrates the coating efficiency percentages for various substrates used with Slot Die Coating Machines. As demonstrated, Substrate C exhibits the highest efficiency, indicating its compatibility with specific coating formulations.

Investing in slot die coating machines presents significant opportunities for long-term operational savings, making a compelling case for businesses aiming to enhance production efficiency. Initially, the capital expenditure might seem substantial; however, a thorough cost-benefit analysis reveals the longevity and durability of these machines often offset their initial costs. Unlike traditional coating methods that often lead to higher material waste and increased labor costs, slot die technology facilitates precision coating applications with minimal material usage, drastically reducing waste and the associated expenses over time.

Moreover, the operational efficiencies gained from slot die coating significantly influence ongoing costs. These machines offer faster production speeds and consistent coating quality, leading to increased throughput and reduced downtime. As companies leverage these efficiencies, they can expect a boost in their overall production capacity, translating into higher revenues. Additionally, less downtime and maintenance needs further contribute to lower operational costs, fostering an environment where businesses can reinvest savings into innovation and growth initiatives.