In the rapidly evolving landscape of manufacturing, optimizing production processes is crucial for companies looking to enhance efficiency and reduce costs.

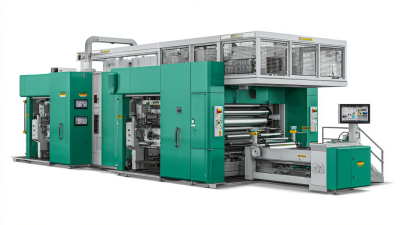

The Slot Die Coating Machine has emerged as a pivotal technology in this arena, offering precise and uniform coating applications for a variety of materials.

According to a recent report by Smithers Pira, the global market for coating technologies is expected to reach $200 billion by 2025, with slot die coating gaining significant traction due to its ability to minimize waste and improve material utilization.

By leveraging the capabilities of the Slot Die Coating Machine, manufacturers can achieve better control over coating thickness, reduce production times, and ensure higher quality outputs.

As the industry continues to prioritize sustainability and performance, the integration of slot die technology represents a strategic approach to streamlining manufacturing processes.

The Slot Die Coating Machine has emerged as a pivotal technology in this arena, offering precise and uniform coating applications for a variety of materials.

According to a recent report by Smithers Pira, the global market for coating technologies is expected to reach $200 billion by 2025, with slot die coating gaining significant traction due to its ability to minimize waste and improve material utilization.

By leveraging the capabilities of the Slot Die Coating Machine, manufacturers can achieve better control over coating thickness, reduce production times, and ensure higher quality outputs.

As the industry continues to prioritize sustainability and performance, the integration of slot die technology represents a strategic approach to streamlining manufacturing processes.

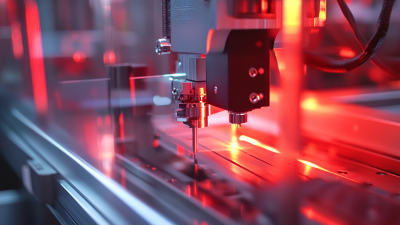

Slot die coating technology is a precise method used in the manufacturing process to apply uniform coatings on various substrates. This technique features a slot-shaped die through which fluid is extruded, allowing for a controlled and consistent layer thickness. Understanding the fundamentals of this technology can greatly enhance production efficiency, particularly in sectors requiring high-quality thin films, such as electronics, pharmaceuticals, and renewable energy.

One of the primary advantages of slot die coating is its ability to minimize material waste while maximizing coverage. Unlike traditional methods that may rely on roller or spray techniques, slot die coating delivers a steady flow of coating material directly onto the substrate. This not only ensures uniformity but also reduces the likelihood of defects caused by overspray or uneven distribution. Additionally, the versatility of slot die systems allows for the application of a wide range of materials, including viscous solutions and inks, making it a popular choice in modern manufacturing environments striving for both quality and sustainability.

The implementation of slot die coating machines in manufacturing processes offers significant benefits, particularly in the production of advanced materials such as perovskite solar cells and films. This technology allows for precise and uniform coating, which is essential for achieving high efficiency in solar cell production. Recent advancements highlight the scalable nature of slot die coating, enabling manufacturers to create functionally gradient thin films that enhance performance across various applications.

In addition to its use in photovoltaics, slot die coating is instrumental in the field of drug delivery systems. By utilizing this method, researchers have developed innovative buccal drug delivery films that improve the efficacy of medication administration. The consistency and control over film thickness achieved with slot die coating are critical for the success of these applications, as they ensure optimal interaction with mucosal membranes. Overall, integrating slot die coating technology into manufacturing processes can lead to enhanced product quality and innovation across diverse sectors.

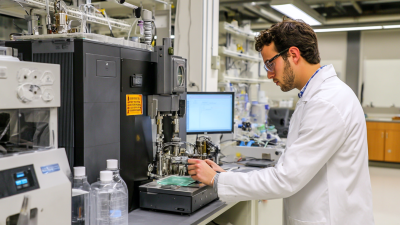

Setting up a Slot Die Coating Machine can significantly enhance your manufacturing process by providing uniform and efficient coatings. Begin by ensuring that you have the appropriate equipment and materials for your specific application. Carefully review the manufacturer's guidelines for installation and operation, paying close attention to safety protocols. Proper calibration of the die is essential; make sure to adjust the coating thickness based on your requirements.

When running your initial tests, consider using a range of speeds and viscosities to determine the optimal settings for your product. Collect data during these tests to identify trends and make necessary adjustments. Monitoring the temperature of both the substrate and coating material will also help maintain consistency and prevent defects.

Tips: Always keep the machine well-maintained and clean to avoid contamination and ensure high-quality results. Regularly inspect the die for wear and tear, as this can affect coating uniformity. Additionally, training your team on the specific nuances of operating the machine will increase efficiency and reduce the likelihood of errors during production. With careful planning and execution, your Slot Die Coating Machine can streamline operations and lead to superior product quality.

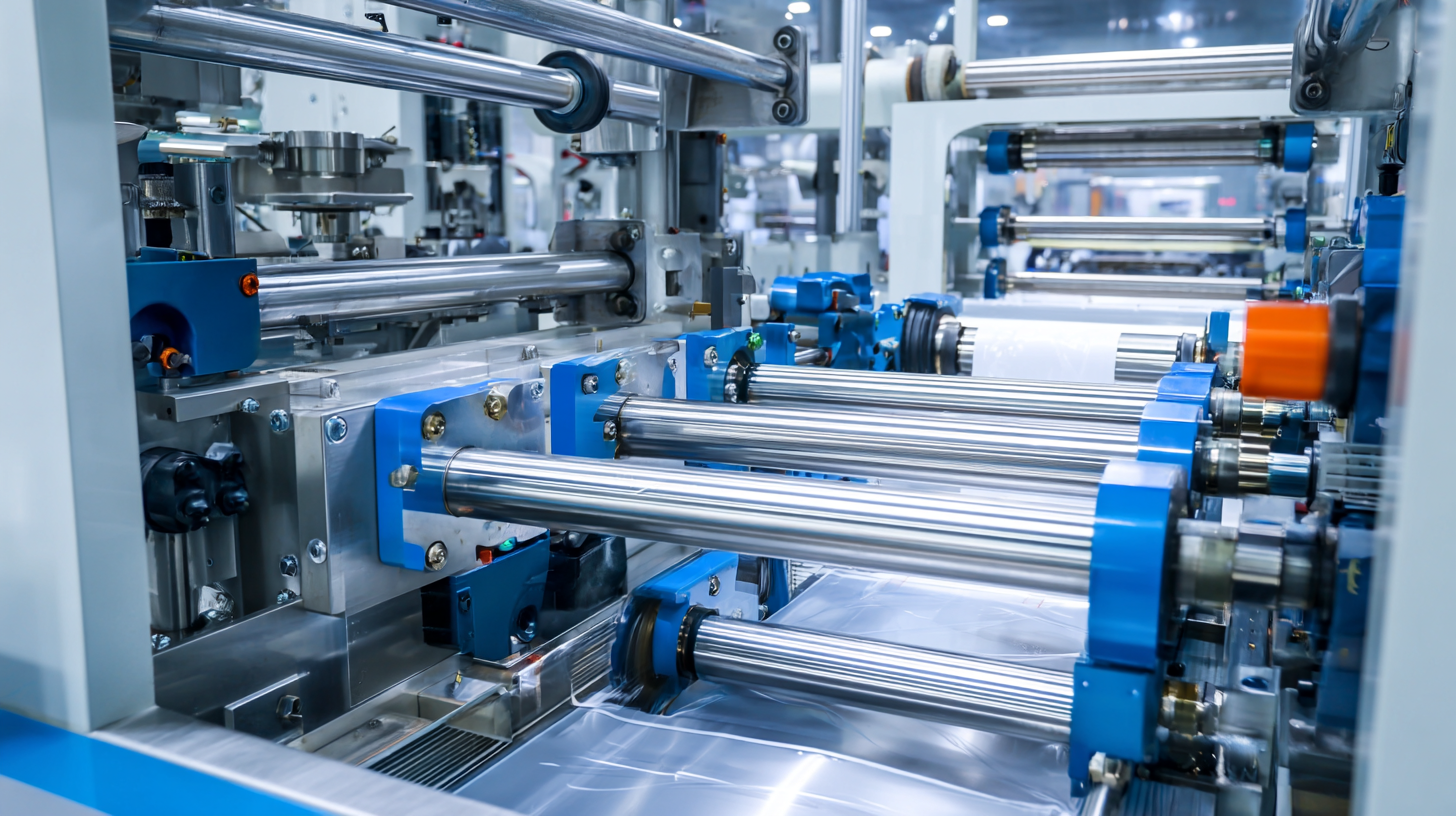

Maintaining and optimizing the performance of a slot die coating machine is essential for enhancing manufacturing efficiency and product quality. According to the Coating Process Optimization Report (2022), facilities that implement regular maintenance can experience up to a 30% increase in coating uniformity and a 25% reduction in material waste. This underscores the importance of routine inspections and adjustments to ensure that the slot die is functioning at peak performance.

Tips: Regularly clean the die and check for wear and tear on the nozzle and slot to prevent potential issues that could lead to uneven coatings. Additionally, calibrating the machine settings based on material viscosity and substrate characteristics can significantly improve output quality. Keeping detailed records of maintenance activities will also help in identifying trends and areas for improvement over time.

Incorporating advanced monitoring technologies can further enhance coating performance. Research has shown that real-time feedback systems can reduce errors by up to 15% during the coating process. This allows operators to make immediate adjustments and maintain optimal conditions. Implementing automation and data analytics not only improves consistency but also streamlines operations, leading to better overall performance and production efficiency.

Analyzing production metrics is crucial for manufacturing sectors looking to enhance efficiency, and using slot die coating techniques can significantly contribute to this goal.

Slot die coating technology ensures uniform distribution of materials, which not only improves product quality but also minimizes wastage. By monitoring key performance indicators, such as coating thickness and material viscosity, manufacturers can fine-tune their processes, leading to optimized resource utilization and time savings.

Implementing slot die coating requires a deeper understanding of these metrics to drive improvements. For example, tracking the speed of the coating process alongside material consumption rates can help identify bottlenecks and areas for enhancement. By regularly analyzing these data points, companies can adapt their techniques and machinery settings, ensuring that each production run is as efficient as possible. This targeted approach to production analysis ultimately slashes operational costs and boosts overall manufacturing productivity.