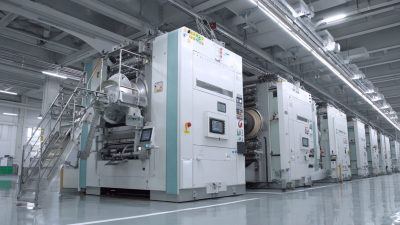

In today's fast-paced manufacturing landscape, optimizing production efficiency is paramount for staying competitive. One innovative solution that has garnered attention is the Carbon Fiber Coating Machine, a technology that enables manufacturers to enhance the durability and performance of their products.

This advanced machinery not only streamlines the coating process but also ensures a consistent and high-quality finish that can significantly reduce production downtime and costs. As industries seek to maximize their output while maintaining quality, understanding how to leverage the capabilities of a Carbon Fiber Coating Machine becomes essential.

This blog will explore best practices, key benefits, and strategies to effectively incorporate this cutting-edge equipment into your production line, ultimately guiding you towards greater efficiency and productivity.

Carbon fiber coating machines have become essential tools in various manufacturing sectors, offering significant advantages in production efficiency and product quality. These advanced systems provide uniform application of carbon fiber coatings, enhancing the durability and performance characteristics of composite materials. According to a report by Grand View Research, the global carbon fiber market is projected to reach USD 6.9 billion by 2025, underlining the increasing demand for high-performance materials that these machines can effectively support.

Key features of carbon fiber coating machines include precision control, automation, and integration capabilities with existing manufacturing processes. For instance, automated systems can reduce labor costs by up to 30% and improve coating consistency, which is critical in industries such as aerospace and automotive. Furthermore, the use of these machines can lead to a reduction in waste, with studies indicating that optimized coating processes can decrease material waste by nearly 20%, significantly impacting overall production costs and sustainability initiatives. The combination of efficiency, cost-effectiveness, and enhanced product quality makes carbon fiber coating machines a valuable asset for manufacturers aiming to optimize their production lines.

| Feature | Description | Benefit |

|---|---|---|

| Automatic Control System | Allows for precise adjustments and monitoring of the coating process. | Enhances production efficiency by reducing errors and downtime. |

| High-Speed Application | Delivers coatings at a rapid pace without compromising quality. | Increases throughput and meets higher demand targets. |

| Multi-Layer Coating Capability | Supports the application of multiple layers of carbon fiber in a single pass. | Reduces cycle time and enhances product durability. |

| Energy Efficiency | Utilizes advanced technologies to minimize energy consumption. | Lowers operational costs while maintaining performance standards. |

| Robust Safety Features | Includes safety sensors and emergency shutdown systems. | Protects operators and minimizes risk of accidents. |

When it comes to enhancing production efficiency, selecting the right carbon fiber coating machine is crucial. An ideal machine should align with your specific production needs, whether you’re working with intricate designs or large-scale outputs. First, assess the capacity requirements; a machine that can handle your volume efficiently will save both time and material costs. Additionally, consider the application methods available, such as spray or dip coating, as this can significantly affect the quality and consistency of the finish.

Another essential factor is the machine's automation capabilities. A high level of automation can streamline processes, reducing labor costs and minimizing human error. Look for machines that offer programmable settings and real-time monitoring to optimize your production workflow. Lastly, evaluate the machine's compatibility with different types of carbon fiber materials. Ensuring that your chosen machine accommodates a range of fibers can provide flexibility and future-proof your operations as material technologies evolve. By taking these factors into consideration, you can select a carbon fiber coating machine that maximizes efficiency and drives productivity in your manufacturing processes.

Maintaining your carbon fiber coating machine is crucial to ensure its optimal performance and longevity. Regular maintenance not only improves efficiency but also minimizes the risk of breakdowns. One essential tip is to conduct routine inspections of all machine components, including hoses, pumps, and spray nozzles. Checking for wear and tear can help you identify potential issues early, preventing larger problems down the line.

Another important maintenance tip is to keep the machine clean. Residue build-up can negatively impact the coating process and lead to inefficiencies. Schedule regular cleaning sessions to remove dust, overspray, and any other contaminants from the machine's surfaces. Additionally, ensure that the coating materials are properly stored and handled to maintain their quality, which, in turn, affects the final product's performance.

Lastly, establish a lubrication schedule for all moving parts to reduce friction and wear. Proper lubrication assists in maintaining smooth operation and can significantly extend the life of your machine. By implementing these maintenance tips, you can optimize your carbon fiber coating machine for maximum efficiency and achieve superior production results.

To maximize efficiency in production with carbon fiber coating machines, it is essential to adopt best practices that leverage advancements in materials and technology. Recent studies indicate that effective utilization of advanced coatings can reduce production downtime by approximately 20%, allowing for higher throughput and better resource management. Embracing controlled-release technology, which has seen significant advancements in related fields, can similarly enhance the performance of carbon fiber products by ensuring consistent application rates and optimal curing conditions.

Moreover, implementing innovative strategies such as the circular economy principles can further boost resource efficiency. For instance, by adopting a "Reduce, Reuse, Recycle" approach in the management of waste materials generated during the coating process, manufacturers can minimize waste and lower operational costs. Such practices not only improve sustainability but also align with the industry's growing focus on environmental stewardship.

Leveraging these insights and technologies will enable manufacturers to refine their production processes, leading to more efficient and eco-friendly output in the carbon fiber coating sector.

The future of carbon fiber coating technology is poised for remarkable innovations that could revolutionize production processes across various industries. As manufacturers seek to improve efficiency and reduce costs, advancements in automated systems and smart technology are paving the way for enhanced precision in coating applications. Expect to see machines that not only streamline the coating process but also integrate real-time monitoring and data analysis, allowing for better quality control and reduced waste.

Tips for optimizing your use of a carbon fiber coating machine include maintaining a regular maintenance schedule to ensure peak performance. Regular calibration of the machine can also prevent inconsistencies in the coating application, improving overall output quality. Additionally, experimenting with different coating materials and settings can help identify the most effective approaches tailored to specific production needs.

As the carbon fiber coating landscape evolves, staying informed about new technologies and techniques will be essential. Engage in industry workshops and forums to share experiences and learn from peers. This proactive approach not only keeps you updated on the latest innovations but also enables collaboration that can lead to unique solutions for maximizing production efficiency.