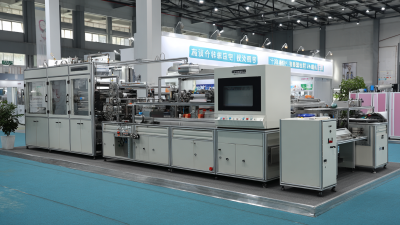

The PET Coating Machine plays a crucial role in the packaging industry by applying a thin layer of polyethylene terephthalate (PET) to various substrates, enhancing their barrier properties and overall durability. As the demand for sustainable and efficient packaging solutions grows, industry experts are continuously evaluating the capabilities and innovations surrounding PET coating technology. Dr. Emily Carter, a leading expert in packaging technology, states, “The PET Coating Machine not only improves product protection but also aligns with our pursuit of environmentally friendly packaging practices.”

In recent years, the rise of eco-conscious consumer behavior has further propelled the need for advanced coating solutions. The PET Coating Machine addresses these requirements by providing a product that minimizes waste and enhances recyclability. This technology allows manufacturers to create packaging that meets stringent safety and quality standards while also contributing to sustainability goals. Understanding the operational aspects of a PET Coating Machine, from its application methods to its integration in production lines, is essential for businesses aiming to stay competitive in the evolving packaging landscape.

As we delve deeper into the mechanics and applications of the PET Coating Machine, we will explore how this innovative equipment operates, its benefits, and how it can serve as a game-changer in achieving efficient and sustainable packaging solutions across various industries.

PET coating technology has emerged as a vital solution in the packaging industry, primarily due to its ability to enhance the durability and appearance of various materials. PET, or polyethylene terephthalate, is a type of thermoplastic that provides superior resistance to moisture, chemicals, and UV light. This makes it an ideal choice for packaging applications, particularly in food and beverage sectors where maintaining product integrity is crucial. The PET coating process involves applying a thin layer of PET onto substrates like paper or cardboard, creating a barrier that extends shelf life while also adding a gloss finish that improves visual appeal.

The application process generally involves extrusion or lamination techniques, allowing for seamless integration of the PET layer onto the base material. As the substrate passes through a PET coating machine, it is subjected to controlled heat and pressure, ensuring optimal adhesion of the PET layer. Additionally, advances in coating technology have introduced options such as bi-oriented PET, which further enhances characteristics like strength and flexibility. By utilizing PET coating, manufacturers not only protect their products but also contribute to sustainability efforts, as PET is recyclable and can be reused in various applications, making it a smart choice for eco-conscious brands.

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| Material Used | Polyethylene Terephthalate (PET) | High strength and durability | Food packaging, electronics |

| Coating Process | Extrusion or spraying | Uniform coating and surface enhancement | Containers, labels |

| Environmental Impact | Recyclable material | Reduced waste and carbon footprint | Sustainable packaging solutions |

| Efficiency | High-speed production | Increased output and reduced time | Mass production of packaging materials |

| Quality Control | Automated monitoring systems | Consistent product quality | Various consumer goods |

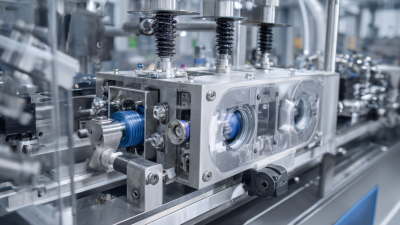

A PET coating machine is an essential piece of equipment used in the packaging industry to apply a layer of polyethylene terephthalate (PET) onto various substrates. This coating offers enhanced durability, moisture resistance, and aesthetic appeal. Understanding the components of a PET coating machine is crucial for grasping how it operates effectively.

The key components include the coating station, drying unit, and curing system. The coating station applies the PET film onto the substrate using rollers or nozzles, ensuring an even layer. Following this, the drying unit utilizes hot air or infrared radiation to remove excess moisture and initiate the curing process. Finally, the curing system solidifies the PET layer, enhancing its adhesion and durability.

Tips: When operating a PET coating machine, ensure that the substrate is clean and free of contaminants to achieve optimal adhesion. Regular maintenance of the drying unit will also help in preventing buildup, which could compromise the efficiency of the coating process. Understanding these components allows operators to fine-tune the machine settings for the best results in packaging solutions.

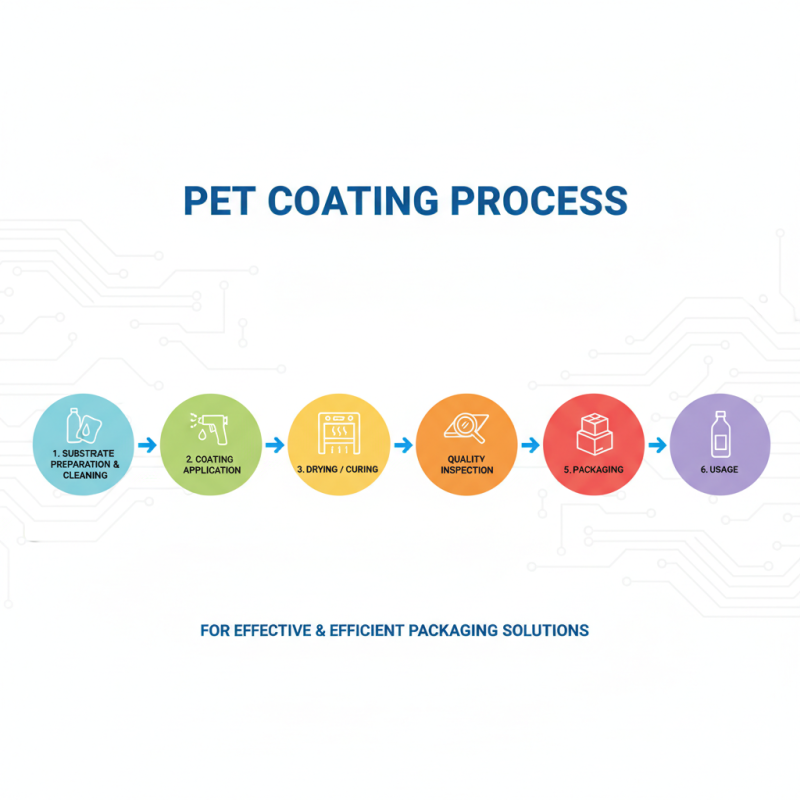

The process of PET coating involves several key steps that ensure the application is both effective and efficient for packaging solutions. Initially, the substrate material, which is often empty bottles or films, is prepared by thorough cleaning to remove any contaminants such as dust, grease, or moisture. This step is crucial, as it guarantees that the PET coating adheres properly to the surface, resulting in a smooth and uniform finish.

Once the preparation is complete, the PET coating machine applies a layer of PET (Polyethylene Terephthalate) to the substrate. This can be achieved through different methods, such as extrusion or spraying. During this phase, precise control over the temperature and speed is essential to ensure an even coating without defects. After the application, the coated materials undergo a curing process, usually involving heat, to enhance adhesion and durability. Finally, the finished products are inspected for quality assurance before being sent for packaging or further use, ensuring they meet industry standards for performance and safety.

PET (Polyethylene Terephthalate) coated materials are becoming increasingly popular in the packaging industry due to their versatility and excellent barrier properties. These materials are primarily used in various applications, including food and beverage packaging, pharmaceuticals, and even industrial products. The global PET packaging market was valued at approximately $24 billion in 2022 and is projected to reach about $39 billion by 2028, reflecting a compound annual growth rate (CAGR) of 8.4% during this period. This growth underscores the rising demand for sustainable and efficient packaging solutions that PET provides.

One of the primary benefits of PET coated materials is their ability to enhance product shelf life by acting as a barrier against moisture, oxygen, and UV light. This characteristic is particularly advantageous in the food and beverage sector, where the preservation of freshness and quality is vital. Additionally, the use of PET coatings on containers not only protects the contents but also improves the overall aesthetic appeal, attracting consumers through vibrant printing and branding capabilities. As businesses increasingly prioritize sustainability, PET's recyclability has become a significant factor in its adoption within packaging solutions.

Tips: When considering PET coated materials for packaging, evaluate their specific attributes, such as thickness and barrier capabilities, to ensure they meet the requirements of your product. Additionally, stay informed about the latest advancements in PET technology, as innovations continue to enhance performance and sustainability in the packaging sector. It's essential to choose suppliers that prioritize environmentally friendly practices to align with the growing consumer demand for sustainable products.

The utilization of PET (polyethylene terephthalate) coating in various industries is becoming increasingly significant due to its numerous benefits. PET coating machines are specifically designed to apply this protective layer, enhancing product durability and extending shelf life. According to a report from the Markets and Markets firm, the global market for PET packaging is expected to grow from USD 32.9 billion in 2020 to USD 45.2 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.6%. This growth is driven by the rising demand for eco-friendly and recyclable packaging solutions.

One of the primary benefits of PET coating is its superior barrier properties. PET-coated products offer increased resistance to moisture, oxygen, and other contaminants, making them ideal for food packaging and pharmaceutical applications. A study by Smithers Pira highlights that 70% of consumers prefer products that come in packaging with advanced protective features. In sectors such as food and beverage, the application of PET coatings has led to a significant reduction in spoilage rates, ensuring that products remain fresh for longer periods. Furthermore, PET's recyclability aligns with the growing emphasis on sustainability within packaging industries, making it an attractive choice for companies aiming to reduce their environmental impact.