In the rapidly evolving manufacturing landscape, the demand for enhanced surface protection solutions has never been higher. PET Coating Machines have emerged as pivotal innovations, significantly improving operational efficiency by up to 30%, according to recent industry reports. With the global protective coatings market expected to reach $25 billion by 2025, manufacturers are increasingly investing in advanced technologies to meet growing consumer needs and stringent environmental regulations. The versatility of PET coatings not only provides superior protection against wear and tear but also incorporates eco-friendly elements, aligning with sustainable manufacturing practices. As industries strive for greater productivity and cost-effectiveness, understanding the transformative role of PET Coating Machines becomes essential for businesses looking to maintain a competitive edge in the market.

In recent years, the manufacturing sector has seen a significant shift towards the adoption of PET coating machines, which have demonstrated remarkable benefits in surface protection processes. According to a report by Smithers Pira, the use of PET coatings can enhance surface durability and chemical resistance, resulting in a 30% increase in operational efficiency. This is particularly advantageous for industries requiring stringent quality standards, such as automotive and electronics, where even minor surface imperfections can lead to substantial losses.

Beyond efficiency, PET coating machines offer versatility through their ability to apply coatings to a wide range of substrates, including metals, plastics, and glass. A study by the Freedonia Group highlighted that the global demand for coated products is expected to generate over $24 billion in revenue by 2025, underscoring the growing reliance on advanced coating technologies. Moreover, the automation inherent in PET coating processes minimizes labor costs and reduces material waste, enhancing the overall sustainability of manufacturing operations. With these advantages, it’s clear that PET coating machines are paving the way for more innovative and efficient manufacturing paradigms.

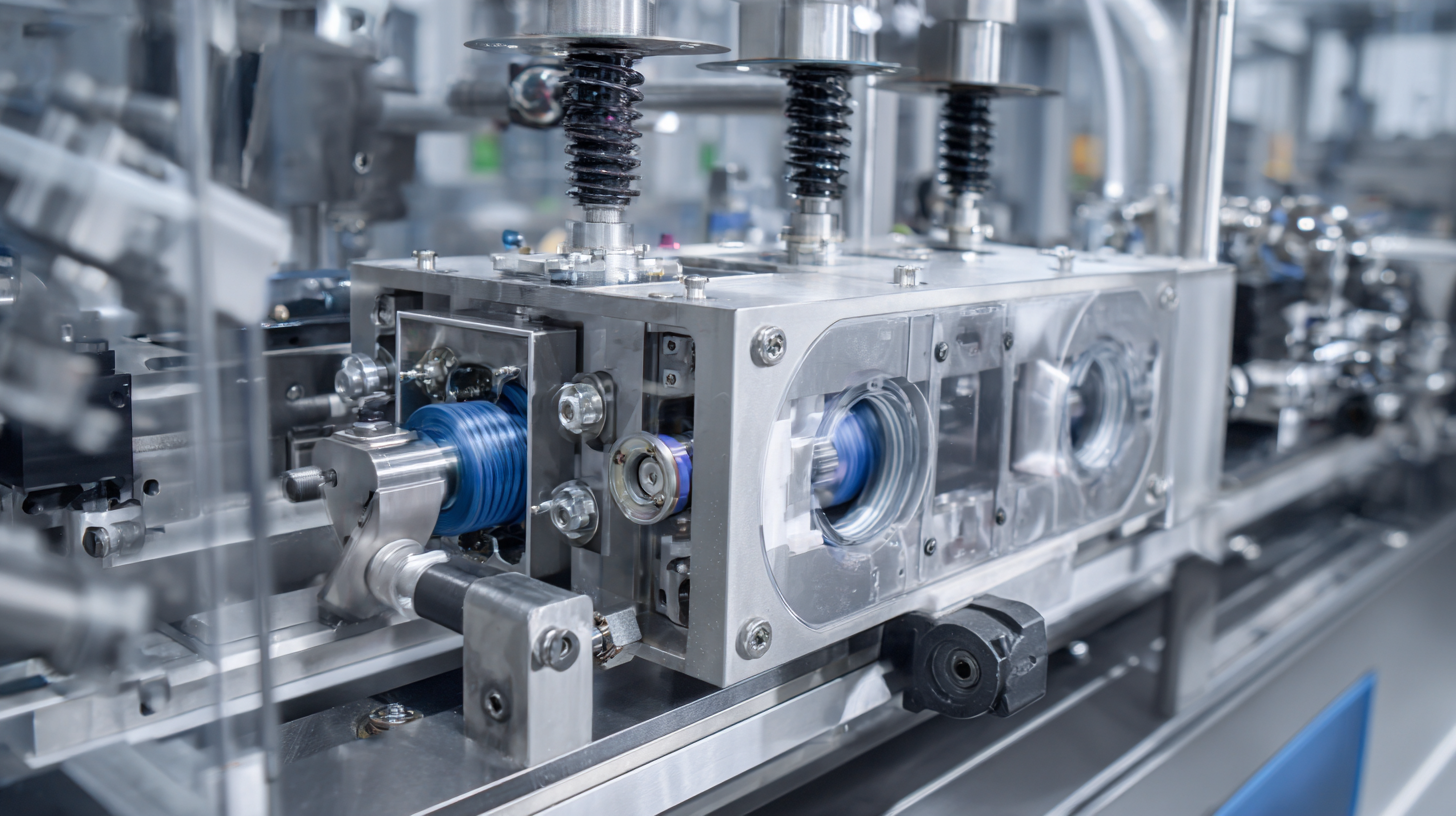

The implementation of PET coating machines in manufacturing has introduced significant advancements in surface protection technology. Central to their efficiency is the integration of precision engineering and automated controls, which streamline the coating process. With advanced sensors and real-time monitoring, manufacturers can ensure optimal application of PET films, reducing waste and minimizing errors. This level of control not only contributes to a more consistent product finish but also accelerates production speed.

Moreover, the development of eco-friendly PET materials enhances the performance of these machines. New formulations provide superior adhesion and durability, allowing for longer-lasting protective coatings. This innovation not only meets the growing demand for sustainable manufacturing practices but also boosts overall system efficiency by extending the lifecycle of the coated products. As companies leverage these key technologies, the benefits of employing PET coating machines become increasingly clear, showcasing a transformative impact on manufacturing processes.

The advent of PET coating technology has transformed surface protection in various manufacturing sectors. Case studies reveal a remarkable increase in efficiency, with some companies reporting up to a 30% enhancement in production rates. For instance, a leading automotive parts manufacturer implemented PET coating machines and witnessed a significant reduction in cycle times, allowing for higher output without compromising on quality. According to a recent industry report from the Coating Research Institute, manufacturers utilizing advanced PET coating techniques have improved their operational throughput by an average of 25%, leading to substantial cost savings.

Another success story comes from a consumer electronics company that adopted PET coating machines to enhance their product durability and aesthetic appeal. This shift not only improved their market competitiveness but also resulted in a customer satisfaction rating increase of 15%. The integration of PET coatings into their production process minimized defects and rework, translating to more streamlined operations. Industry analysts speculate that as manufacturers continue to embrace innovative coating solutions, the overall market for PET coating technologies could grow by over 40% in the next five years, underscoring the significance of these advancements in driving efficiency and sustainability in manufacturing.

In the realm of surface protection, PET coating is emerging as a game-changer when compared to traditional methods. While conventional coatings often involve labor-intensive processes that can lead to inconsistencies, PET coating machines streamline this with automated precision. This not only enhances the uniformity of the application but also reduces the time required, improving overall manufacturing efficiency by up to 30%. Additionally, PET coatings possess superior durability against scratches and environmental factors, making them an ideal choice for industries that demand high-quality finishes.

Tips to consider when choosing between PET and traditional methods include evaluating your production scale and the specific environmental conditions your products will face. PET coatings are not only efficient but also more eco-friendly, reducing waste in the manufacturing process. Furthermore, ensure that your team is adequately trained in operating the new PET coating equipment to fully realize its benefits.

By embracing PET coating technology, manufacturers can enhance their product quality and operational efficiency. This transition can significantly impact production timelines, lowering costs associated with rework and material waste. Choosing the right surface protection method is essential for maintaining competitive edge in today’s fast-paced market.

| Method | Efficiency (%) | Cost per Unit ($) | Environmental Impact (Rating 1-5) | Durability (Years) | Application Speed (m²/h) |

|---|---|---|---|---|---|

| PET Coating | 90% | 1.50 | 4 | 5 | 100 |

| Traditional Coating | 60% | 2.00 | 3 | 3 | 50 |

The surface protection technology landscape is rapidly evolving, driven by the integration of advanced materials and innovations in production processes. The anticipated growth of the global aircraft flight control systems market, projected to expand from USD 332 billion in 2025 to USD 571.8 billion by 2032, highlights the increasing demand for efficient manufacturing solutions. This growth, equivalent to an annual growth rate of 8.08%, underscores the importance of adopting advanced surface protection methods that can enhance durability while reducing production costs.

In 2025, the emergence of AI agents is expected to revolutionize various sectors, including surface protection technology. These intelligent systems can optimize manufacturing processes, thereby increasing efficiency by as much as 30% through innovative application of PET coating machines. As the semiconductor industry faces unprecedented challenges amid rapid AI and HPC developments, the demand for robust, high-performance surface protection solutions is set to rise. Reports indicate that the intersection of AI technology with manufacturing will lead to breakthrough innovations, making surface protection not just a necessity, but a cornerstone of future industrial advancements.