In recent years, the dental care industry has witnessed a remarkable transformation with the advent of innovative technologies aimed at enhancing oral aesthetics. Among these advancements, the Teeth Whitening Patch Coating Machine has emerged as a game-changer, providing unparalleled efficiency in teeth whitening procedures. According to a recent report from MarketsandMarkets, the global teeth whitening products market is projected to reach USD 7.4 billion by 2025, driven by increasing awareness of personal grooming and aesthetics. The Teeth Whitening Patch Coating Machine offers several benefits, including user-friendly operation, reduced application time, and consistent whitening results, which are vital in meeting the growing demand for effective at-home whitening solutions. As the industry evolves, these machines stand at the forefront of revolutionizing teeth whitening processes, making them accessible and efficient for both consumers and dental professionals alike.

As the demand for effective teeth whitening solutions continues to rise, innovative approaches in teeth whitening patch production machinery have become essential for manufacturers looking to stay competitive. According to a recent market research report from Grand View Research, the global teeth whitening products market is expected to reach USD 7.4 billion by 2028, growing at a CAGR of 5.5%. This surge in demand highlights the necessity for advanced production techniques that enhance both efficiency and product quality.

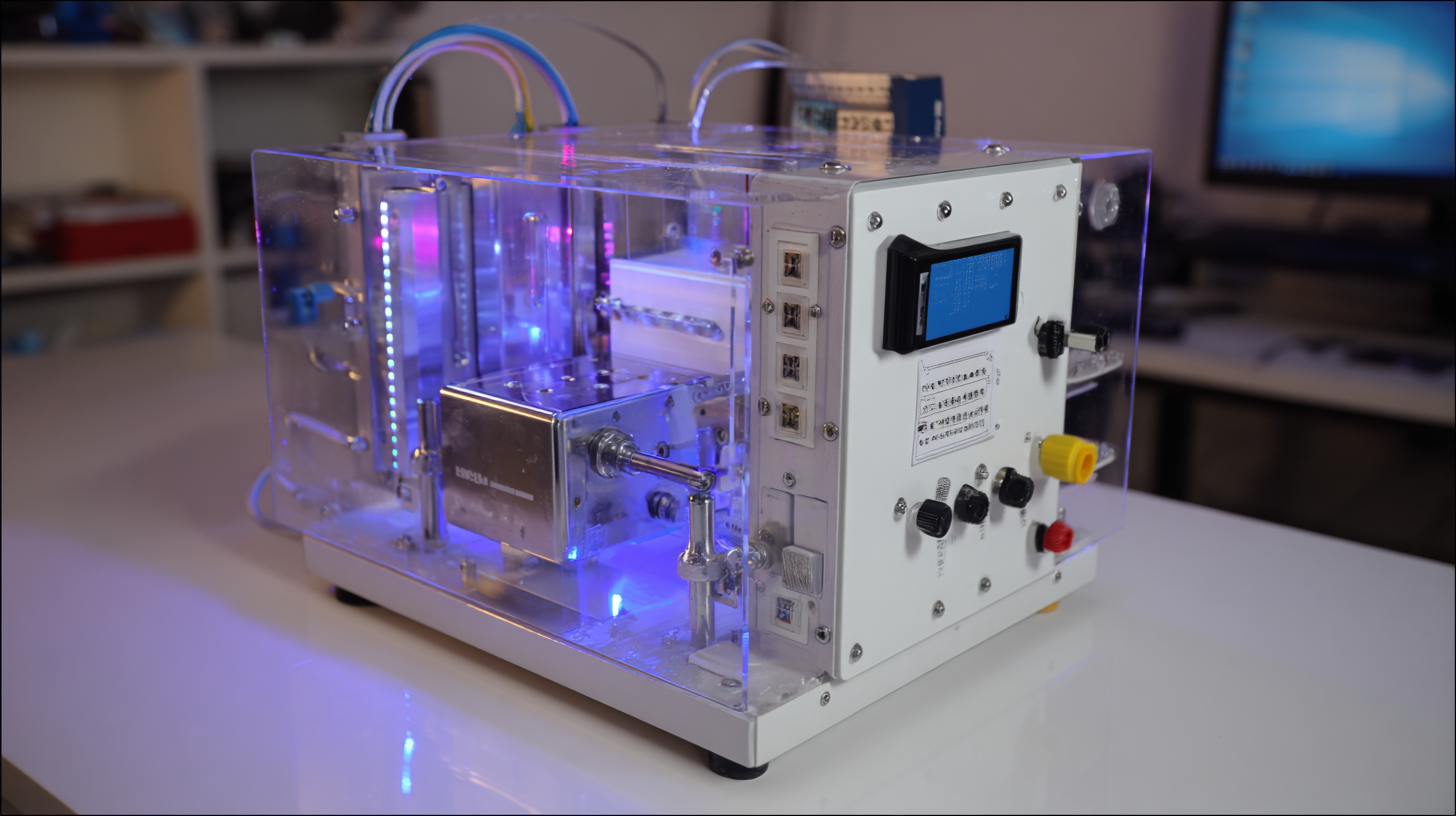

One revolutionary method includes the integration of automation and precision coating technologies in the production process. By utilizing automated systems, manufacturers can achieve consistent patch thickness, which is crucial for effective whitening. Furthermore, recent advancements in nanotechnology have allowed for the development of more effective whitening agents that can be seamlessly incorporated into the patches. A report from ResearchAndMarkets indicates that improved formulation technologies could enhance whitening effectiveness by up to 50%, making the development of advanced coating machines pivotal for the industry.

Additionally, sustainability is becoming a significant focus in the production of dental care products. Many companies are exploring eco-friendly materials and processes to minimize environmental impact. The industry has seen a shift towards biodegradable patches and recyclable packaging, responding to consumer demand for sustainable options. This strategic shift not only meets market demand but also aligns with the growing trend of corporate responsibility in the health and beauty sectors.

The advancements in coating technology for teeth whitening patches have significantly enhanced the efficacy and user experience of these products. With the introduction of innovative materials and application techniques, manufacturers are now able to create patches that not only deliver superior whitening results but also adhere better to the teeth surface. This ensures that the active whitening agents are in contact with the enamel for a longer duration, maximizing their effectiveness.

Tips for users looking to achieve the best results with teeth whitening patches include ensuring that your teeth are clean and dry before application, as this allows for optimal adhesion and absorption of the whitening agents. Additionally, it's advisable to follow the recommended usage duration strictly; overusing the patches may lead to sensitivity. Finally, integrating a regular oral hygiene routine will help maintain the achieved whiteness and prevent any potential discoloring from external factors.

As the technology continues to evolve, users can expect even more efficient and comfortable whitening solutions. The transition from traditional whitening methods to these cutting-edge patches marks a significant leap forward in cosmetic dentistry, promising brighter smiles with minimal effort.

In the burgeoning market of dental aesthetics, the role of quality assurance in teeth whitening patch manufacturing cannot be overstated. According to a recent report by Grand View Research, the global teeth whitening market is expected to reach USD 7.4 billion by 2025, demonstrating an increasing consumer demand for effective whitening solutions. This surge necessitates robust quality control measures at every stage of production. Quality assurance ensures that each batch of teeth whitening patches meets stringent safety and efficacy standards, which not only safeguards consumer health but also enhances brand reputation.

Implementing comprehensive quality assurance protocols, such as ISO 13485 compliance for medical devices, is crucial in maintaining product performance. A study published in the Journal of Dentistry highlighted that improper production processes could lead to inconsistent whitening outcomes and potential adverse effects. By utilizing advanced techniques like real-time analytical testing and automated quality checks in the production of whitening patches, manufacturers can minimize risks and optimize product integrity. This strategic approach not only leads to higher customer satisfaction but also positions companies competitively within an evolving market landscape.

In recent years, the demand for effective teeth whitening solutions has led to significant advancements in the production of whitening patch machines. As consumers become more aware of sustainability, manufacturers are prioritizing eco-friendly practices in their operations. Sustainable production not only reduces the environmental impact but also appeals to conscientious consumers who seek products that align with their values.

One revolutionary technique gaining traction in the manufacturing process is the use of biodegradable materials for the patches themselves. By sourcing renewable resources and minimizing plastic use, companies can create whitening patches that are both effective and environmentally friendly. Additionally, energy-efficient machinery is being implemented to reduce carbon footprints during production. These innovations ensure that the benefits of brightening smiles do not come at the expense of our planet's health.

Moreover, adopting circular economy principles is becoming a priority for many businesses in this field. This approach focuses on designing products that can be easily recycled or reused, thus minimizing waste. By integrating these sustainable practices, manufacturers are not only contributing to a greener future but also setting new standards in the industry. As the market for teeth whitening products continues to grow, the commitment to sustainability will undoubtedly shape its future landscape.

This chart illustrates the production efficiency of teeth whitening patch coating machines over the first half of the year. It showcases a steady increase in units produced each month, reflecting sustainable practices and advancements in production techniques.

As the global demand for teeth whitening products continues to surge, innovative distribution strategies from Chinese manufacturers are paving the way for a competitive edge in the market. The expansion of the teeth whitening patch coating machine production has enabled the industry to tap into the growing desire for at-home whitening solutions. By providing easy access to these products, manufacturers can effectively reach a wider audience, including both adults and children.

To maximize success in this booming market, companies should consider leveraging e-commerce platforms and social media advertising to enhance visibility. Engaging with consumers through targeted campaigns can create a stronger brand presence and connect with potential customers.

Additionally, brands should focus on incorporating user-friendly designs in their products. This can make the teeth whitening experience more accessible and appealing to a broader demographic. Simplifying the use of whitening patches can encourage more consumers to try and adopt these innovative solutions, ultimately driving sales and brand loyalty.