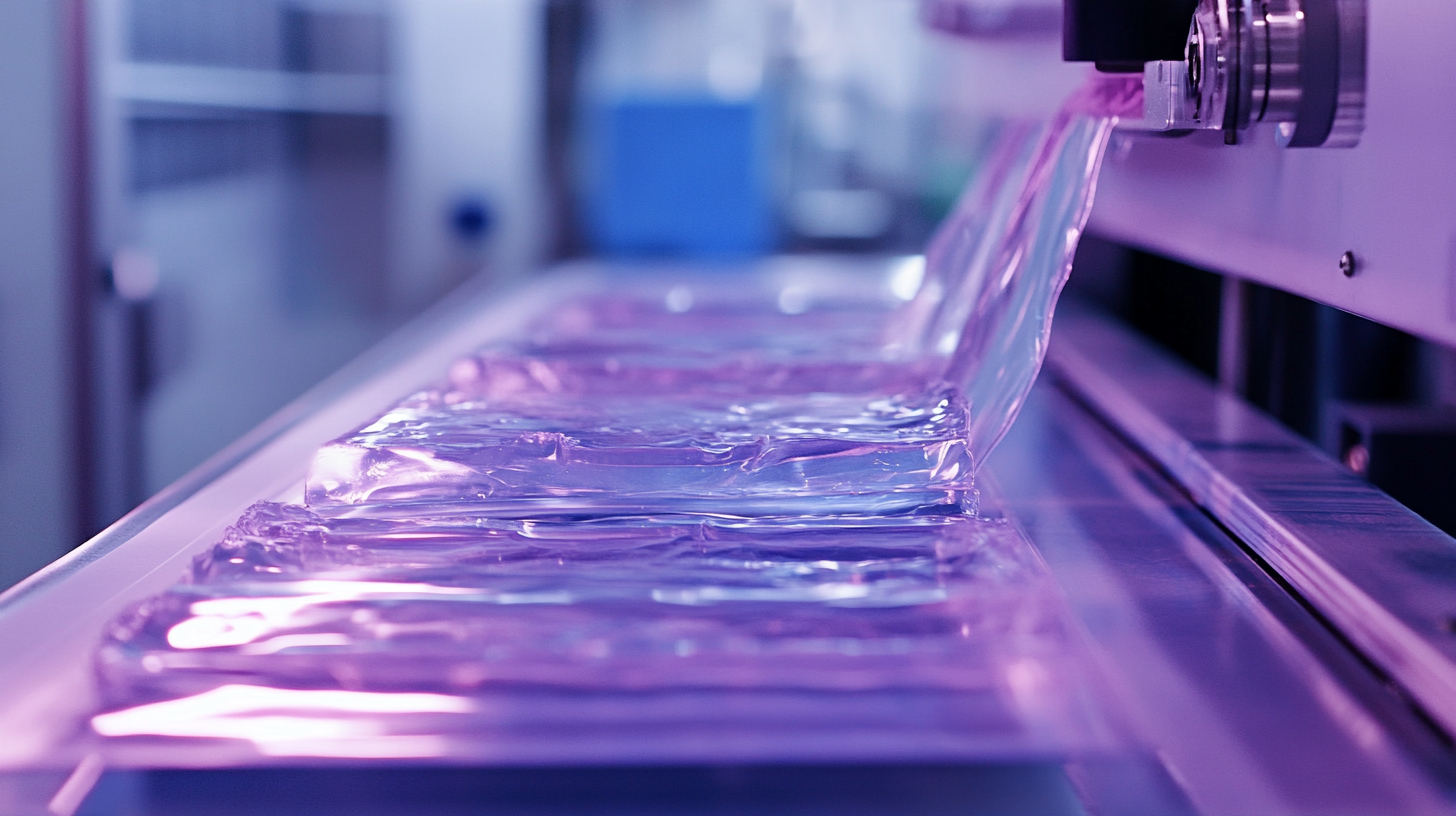

In the rapidly evolving world of material science, the advent of hydrogel coating machines is heralding a new era in surface protection technology. These innovative machines are engineered to apply advanced hydrogel coatings that not only enhance the durability of various surfaces but also provide unmatched resistance to environmental factors. As industries face increasing demands for resilient materials, the significance of hydrogel coating machines becomes evident. They offer a versatile solution for protecting an array of products, from electronics to automotive components, thus ensuring longevity and superior performance. This blog will explore the transformative potential of hydrogel coating machines, delve into their applications, and discuss the future advancements that are set to revolutionize surface protection as we know it.

Hydrogel coatings have gained significant traction in various industries due to their unique properties, including high water absorption and biocompatibility. Recent research published by ACS Biomaterials Science & Engineering highlights the tunability of zwitterionic hydrogel coatings, emphasizing their antifouling and mechanical properties that depend on cross-link density. For instance, optimizing the cross-link density can enhance the durability of these coatings, making them ideal for applications in medical devices such as urinary catheters, where lubrication and antibacterial features are critical for preventing tissue trauma and infections.

Moreover, hydrogel coatings are being explored for marine antifouling applications, showcasing their potential in environments where sediment accumulation can hinder functionality. The studies indicate that zwitterionic hydrogel-based coatings exhibit improved anti-sediment capabilities, achieving performance levels comparable to traditional biocidal coatings. Additionally, the development of lignin-based ultrathin hydrogel coatings demonstrates innovative approaches to substrate adhesion through hydrophobic interactions, signifying a move towards more sustainable and efficient surface protection technologies. With such advancements, hydrogel coatings are poised to revolutionize surface protection across multiple sectors, from biomedical to environmental applications.

| Property | Description | Benefits | Applications |

|---|---|---|---|

| Transparency | Hydrogels are typically clear or translucent. | Maintains product aesthetics. | Smart devices, automotive displays. |

| Flexibility | Can stretch and conform to various surfaces. | Enhanced durability in high-stress environments. | Wearable technology, consumer electronics. |

| Self-Healing | Ability to recover from minor damages. | Increased lifespan of coating. | Automotive surfaces, protective gear. |

| Water Resistance | Prevents water penetration and damage. | Protection against moisture-related issues. | Outdoor equipment, smartphones. |

| Chemical Resistance | Resists degradative effects of chemicals. | Maintenance of surface integrity. | Industrial applications, laboratory equipment. |

The market for hydrogel coating machines is rapidly evolving, with innovative technologies making significant strides in both efficiency and functionality. One of the most exciting advancements is the integration of AI-driven automation, which allows these machines to optimize the coating process in real-time. This not only minimizes human error but also reduces material waste, making hydrogel applications more sustainable and cost-effective. Additionally, the latest models feature enhanced precision controls that ensure a uniform application across various surface types, from electronics to medical devices.

Another noteworthy development is the introduction of eco-friendly hydrogel formulations that cater to growing environmental concerns. These new hydrogels are derived from sustainable materials and are designed to be easily biodegradable, pushing the industry toward more responsible manufacturing practices. Furthermore, manufacturers are focusing on modular designs for their coating machines, allowing businesses to customize their equipment based on specific production needs. This flexibility makes it easier for companies to adapt to changing market demands and optimize their operations. As these innovative technologies converge, they promise to revolutionize surface protection across many industries.

Hydrogel coatings are rapidly gaining traction across various industries, proving to be a game-changer in surface protection. From consumer electronics, where smartphones and tablets often face daily wear and tear, to the automotive sector, where durability is key, hydrogel coatings offer unparalleled advantages. These coatings not only enhance the aesthetic appeal of devices but also provide a robust defense against scratches, moisture, and dust, ensuring longevity and maintaining their perfect condition.

When applying hydrogel coatings to electronics, it's essential to clean the surface thoroughly to prevent any dirt or debris from getting trapped underneath. A simple microfiber cloth can work wonders in achieving a smooth application. For automotive applications, consider using hydrogel coatings on high-impact areas such as bumpers and fenders. Not only does this protect your vehicle's paint from chips and scratches, but it also makes it easier to wash off dirt and grime.

Furthermore, staying updated with the latest advancements in hydrogel technology can give you a competitive edge. Regular research on new coating formulations and application techniques ensures that you are using the most effective products available. By embracing this innovative technology, businesses can significantly improve product performance and customer satisfaction.

Hydrogel coatings are emerging as a revolutionary solution for surface protection, but their environmental impact raises crucial sustainability and safety concerns. As these coatings gain popularity in various industries, it is essential to analyze their life cycle—from production to disposal. While hydrogels are often praised for their biocompatibility and non-toxic properties, the materials and processes used in manufacturing them can have significant ecological footprints. This dichotomy sparks a necessary dialogue about how we can innovate while ensuring that the benefits do not come at the cost of environmental health.

In addition to the production processes, the biodegradability of hydrogel coatings plays a vital role in their overall sustainability. Current formulations vary in their ability to break down in natural environments, and some may contribute to long-term pollution if not properly managed. Moreover, potential leaching of chemicals during degradation poses risks to local ecosystems. Therefore, the industry must prioritize research and development of eco-friendly materials and techniques that enhance the safety and sustainability of hydrogel coatings. By addressing these challenges, we can better harness the advantages of hydrogel technology while safeguarding our planet for future generations.

The future of hydrogel coating machines is poised for unprecedented advancements, driven by the growing demand for enhanced surface protection across various industries. According to a report from MarketsandMarkets, the global market for hydrogel coatings is projected to reach $13.6 billion by 2025, expanding at a CAGR of 8.5% from 2020 to 2025. This surge is attributed to the increasing application of hydrogels in sectors such as medical, automotive, and consumer electronics, where protection against environmental factors is paramount.

Innovations in machine technology are set to improve both the efficiency and effectiveness of hydrogel application processes. Emerging trends indicate a shift towards automation and smart technology integration. A recent study by ResearchAndMarkets highlights that the integration of IoT and AI in hydrogel coating machines will not only reduce production costs but also enhance precision, allowing for tailored solutions that meet specific surface protection needs. As manufacturers adopt these advanced technologies, the future of hydrogel coating promises to offer robust solutions that exceed current protective standards while catering to an expanding range of surfaces.