The Roll-to-Roll Laboratory Coating Machine is a pivotal technology in the realm of materials science and manufacturing processes, offering a unique solution for the continuous coating of flexible substrates. This innovative machine operates by feeding a roll of material through various coating stages, enabling the application of different substances such as inks, adhesives, or functional coatings in a highly efficient manner.

As industries increasingly focus on optimizing production speeds and cost-effectiveness while maintaining high-quality standards, understanding the workings and advantages of the Roll-to-Roll Laboratory Coating Machine becomes essential. This article will delve into the functionality of this equipment, exploring its various components, operational principles, and the benefits it offers in research and development settings, ultimately answering the question of why this technology is indispensable in today's fast-evolving production landscape.

A roll-to-roll (R2R) laboratory coating machine plays a crucial role in modern manufacturing, particularly in the production of

flexible electronics, photovoltaics, and biomedical devices. This machine employs a continuous process where substrates are

coated as they roll through various application stations. Its ability to handle large areas uniformly with high precision makes it ideal for

research and development, allowing manufacturers to create prototypes and small batches efficiently.

One defining feature of R2R coating machines is their versatility. They can apply various types of coatings, including inks, paints, and functional

films, enabling the development of innovative products. The technology also allows adjustments in coating thickness and

patterns, catering to specific application needs.

Tips: When working with a roll-to-roll coating machine, ensure optimal environmental conditions, such as controlled humidity

and temperature, to maintain coating quality. Regular maintenance checks are essential to prevent any issues that could disrupt production. Additionally, testing different coating

speeds can help optimize throughput and material usage for cost-effective production.

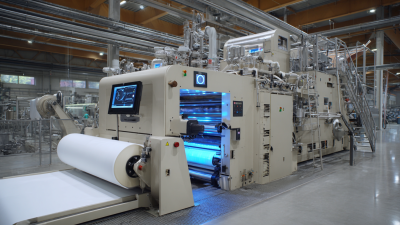

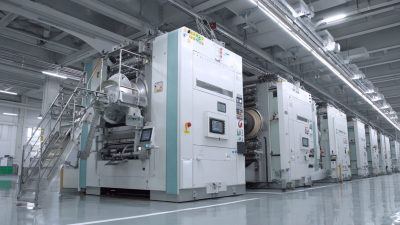

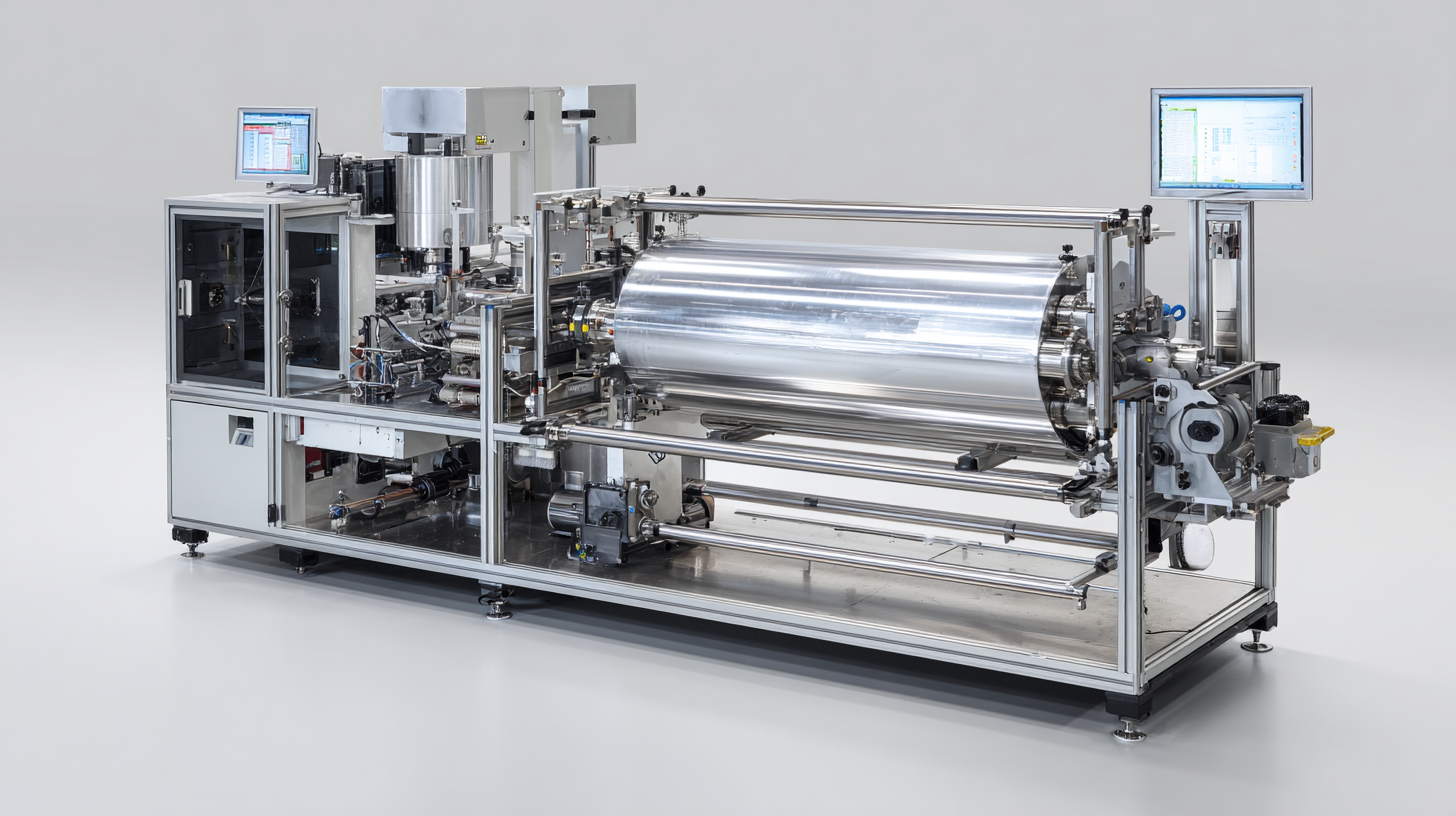

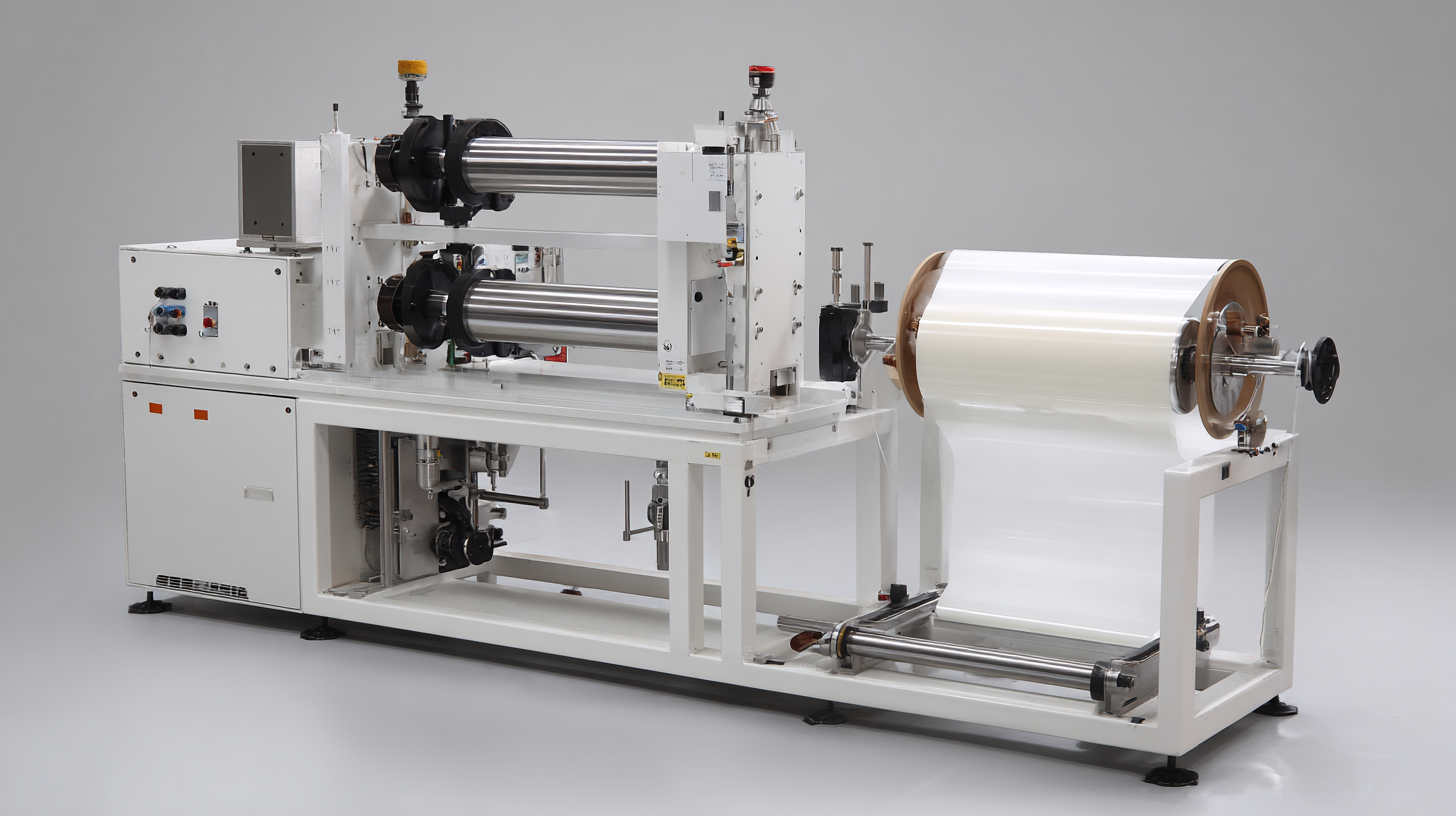

Roll-to-roll (R2R) coating machines are essential in the manufacturing of a variety of products, ranging from electronics to flexible displays. These machines utilize a continuous web of substrate material that is fed through a series of coating stations where layers of materials are applied. The efficiency of R2R systems largely depends on their key components, which include unwind and rewind stations, coating heads, drying units, and control systems.

Unwind and rewind stations are crucial for managing the flow of the substrate. The unwind station initiates the process by releasing the roll of material, while the rewind station collects the finished product. Coating heads, which can vary in design—such as gravure, slot die, or blade coaters—apply the coating liquid in a uniform manner. This is followed by drying units, which use heat or ultraviolet light to solidify the coatings quickly. Advanced control systems monitor parameters like speed, temperature, and coating thickness, ensuring high precision and quality in the final product. Together, these components create a streamlined process, making roll-to-roll technology a vital asset in modern manufacturing.

| Component | Description | Function | Key Technologies |

|---|---|---|---|

| Web Feed System | Initial input mechanism that supplies the substrate. | Ensures consistent material feed during the coating process. | Tension control, Edge guide systems |

| Coating Head | Applies the coating material onto the substrate. | Uniform application of coating for optimal thickness. | Slot-die, Gravure, Flexo coating technologies |

| Drying System | Removes solvent or moisture from the coated film. | Accelerates drying to improve production rates. | Infrared, Hot air, UV drying technologies |

| Rewind System | Collects the coated and dried film. | Facilitates post-coating processing and storage. | Automatic tension control, Roll handling systems |

| Control System | Monitors and regulates the entire coating process. | Ensures precision and repeatability in coating applications. | PLC, HMI, Sensors, Feedback systems |

Roll-to-roll (R2R) laboratory coating machines are innovative tools designed for the continuous application of coatings onto flexible substrates. The working principle involves unwinding a roll of substrate, passing it through a coating station where a liquid or polymer material is applied, and then winding it back onto a spool. This process enables high throughput and uniform coating over large areas, making it ideal for applications in electronic, medical, and photovoltaic industries.

During the coating process, the substrate is usually guided through various rollers to ensure a smooth application. Different coating techniques such as slot-die, gravure, or spray can be employed, depending on the desired coating thickness and properties. The machine’s ability to finely control parameters like coating speed, viscosity, and temperature significantly affects the final product’s quality.

Tips: Before operating a roll-to-roll coating machine, always ensure that the substrate material is compatible with the coating solution. Regularly clean and maintain the machine to prevent contamination and ensure consistent results. Additionally, conducting small-scale tests can help optimize the coating process before moving to larger production runs.

Roll-to-roll (R2R) coating machines play a crucial role in various industries by enabling the mass production of coated materials on flexible substrates. These machines are widely used in the manufacturing of electronic components, such as flexible displays and organic light-emitting diodes (OLEDs). The ability to coat large rolls of material continuously makes R2R technology particularly valuable in the electronics sector, where precision and efficiency are paramount.

In addition to electronics, roll-to-roll coating machines find significant applications in the production of solar cells and battery technology. The use of thin films in solar panels allows for lightweight and flexible energy solutions, while R2R processes enhance productivity and reduce material waste. Furthermore, industries such as automotive and packaging utilize R2R technology for coating applications that improve durability and performance, offering cost-effective solutions in high-volume production scenarios. Overall, the versatility of roll-to-roll coating machines positions them as essential tools in modern manufacturing, serving diverse markets and driving innovation across multiple sectors.

Roll-to-roll (R2R) coating technology is witnessing significant growth projections as we approach 2030, mirroring trends in related industries such as low-k dielectric materials and two-layer flexible copper clad laminates. The low-k dielectric materials market, valued at $7 billion in 2022, is expected to reach $11.5 billion by 2030, growing at a compound annual growth rate (CAGR) of 6.0% from 2024 to 2030. This surge indicates a robust demand for advanced materials, which directly benefits R2R coating applications.

Roll-to-roll (R2R) coating technology is witnessing significant growth projections as we approach 2030, mirroring trends in related industries such as low-k dielectric materials and two-layer flexible copper clad laminates. The low-k dielectric materials market, valued at $7 billion in 2022, is expected to reach $11.5 billion by 2030, growing at a compound annual growth rate (CAGR) of 6.0% from 2024 to 2030. This surge indicates a robust demand for advanced materials, which directly benefits R2R coating applications.

Similarly, the two-layer flexible copper clad laminate market is projected to grow from $350 million in 2022 to a remarkable figure by 2030, with a CAGR of 6.6%. These developments suggest that roll-to-roll coating technologies will play a crucial role in manufacturing processes, as they enable the efficient production of high-performance electronic components that support the expanding market demands.

Tips: For companies looking to leverage R2R technology, investing in state-of-the-art coating machines can optimize production efficiency and material utilization. Additionally, keeping an eye on market trends in complementary industries will provide insights into future opportunities and potential collaborations. Companies should also focus on research and development to innovate in coating techniques, ensuring they stay ahead in a competitive landscape.