When selecting a UV Coating Machine, many factors come into play. Experts emphasize the importance of making an informed choice. John Smith, a leading authority in the UV coating industry, once stated, “Choosing the right UV Coating Machine can drastically impact your production quality.” His advice resonates deeply within the industry, highlighting the need for careful consideration.

The market is filled with various UV Coating Machines, each offering unique features. Understanding these features can be overwhelming. Many companies rush their decisions, prioritizing price over performance. However, this can lead to regrettable outcomes. Investing in a high-quality machine pays off in the long run, saving time and costs.

Additionally, it is essential to evaluate your specific needs. Not all UV Coating Machines are created equal; they cater to different applications. Reflecting on the right fit for your production line can make a significant difference. Things to consider include speed, ease of use, and maintenance requirements. The perfect choice will enhance your workflow and product finish, aligning with your business goals.

UV coating technology has transformed the manufacturing landscape. It provides durable and high-gloss finishes. According to a recent industry report, 65% of manufacturers now use UV coating for various applications. This innovation meets the demand for faster production and improved surface protection.

One major benefit of UV coating is its quick curing time. The process allows for immediate handling and packing. This can lead to a 30% increase in efficiency. However, not all UV coatings deliver the same performance. Variations in formulations can impact adhesion and durability. Manufacturers need to assess compatibility with their substrates.

Environmental considerations are crucial as well. UV coatings typically contain fewer volatile organic compounds (VOCs). Studies show a reduction in emissions by up to 50% compared to traditional coatings. However, some UV curing processes require energy-intensive UV lamps. This raises questions about sustainability in the long term. The balance between performance and environmental impact is vital for responsible manufacturing.

When selecting a UV coating machine, several key factors should come into play. The size of your projects is crucial. Smaller machines may suffice for modest tasks, while larger setups are necessary for bigger jobs. It’s essential to evaluate your production volume as well. High-demand operations require machines that can keep pace without compromising quality.

Consider the machine’s speed and efficiency. A slow machine can lead to bottlenecks in your workflow. Look for features like automated processes, which can enhance productivity. However, more features can also complicate operation. It’s vital to strike a balance between capability and usability.

Tip: Check the machine's maintenance requirements. A complex maintenance routine may hinder your workflow. Ensure you choose a user-friendly design. Moreover, seek machines known for their reliability. Remember, a dependable machine will save you time and money. Reflect on your specific needs and don’t rush the decision. A hasty choice might lead to issues later.

When considering a UV coating machine, understanding production volume requirements is crucial. Analyzing your current and future output needs can drastically affect the machine you choose. For instance, a facility producing 5,000 units per day may need a more robust solution compared to one producing 500. The efficiency and speed of UV coating machines should align with these production demands.

Industry reports indicate that manufacturers often face challenges in meeting volume requirements. About 20% of companies struggle with bottlenecks during peak production times. Small production runs can benefit from compact machines, which may lack the speed required for larger operations. Conversely, oversized machines can create unnecessary energy costs and resource waste.

Additionally, the application type plays a role in volume considerations. For example, high-gloss finishes may require different processing speeds than matte coatings. Each coating type has its own curing time and thickness specifications, directly impacting overall throughput. Flexibility in production lines helps accommodate various coating needs, but can complicate equipment selection. Careful evaluation of these factors can lead to informed decisions, aligning capabilities with realistic production goals.

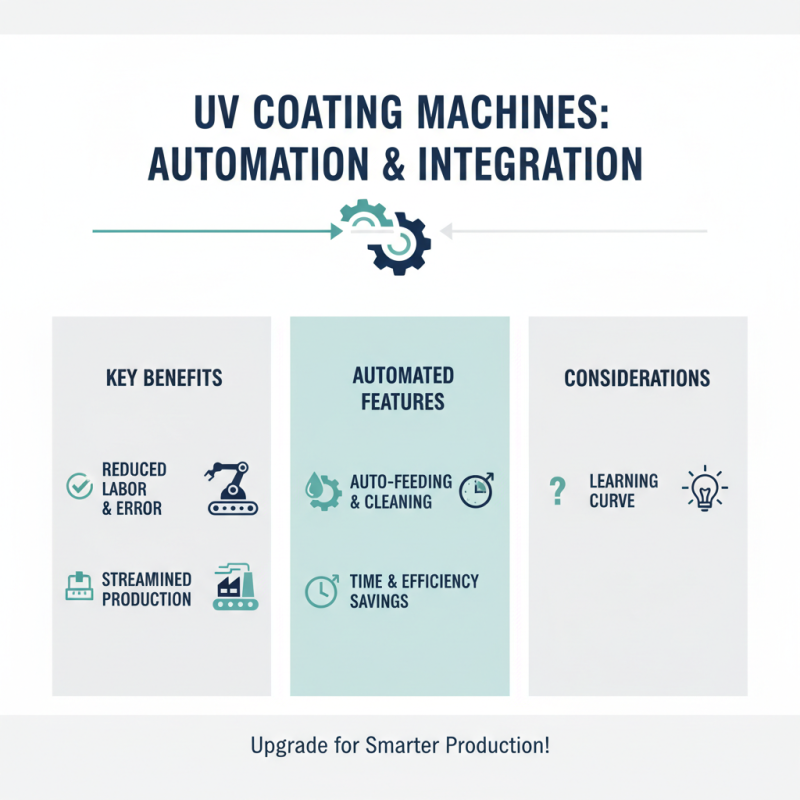

When evaluating UV coating machines, automation and integration features are crucial. Many machines now offer automated processes. This reduces manual labor and minimizes human error. A fully automated system can streamline production. It often includes features like auto-feeding and auto-cleaning. Such capabilities save time and increase efficiency. However, automation can come with a learning curve.

Integration with existing systems is another key aspect. Ensure the UV coating machine works seamlessly with your current setup. Compatibility can affect your overall workflow. Poor integration may lead to delays and increased costs. Keep in mind that not all machines offer the same level of integration. Some may require additional hardware or software. Be aware that investing in complex systems might not always yield immediate benefits.

Consider the future of your production. Technology evolves rapidly, and your equipment should adapt. Machines that allow easy upgrades are worth considering. Reflect on potential changes in your production needs. Will your machine still be relevant in a few years? It's essential to think long-term when making such decisions. Balancing automation and integration can be challenging, but it's necessary for growth.

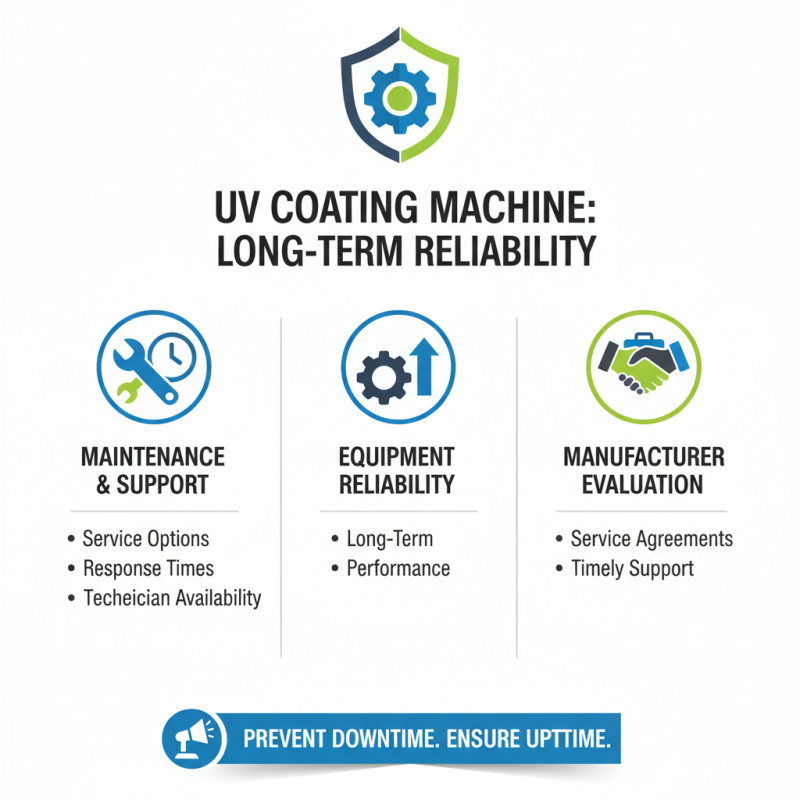

Choosing a UV coating machine involves various considerations, especially regarding maintenance and support services. These factors often determine the long-term reliability of your equipment. It is crucial to evaluate the manufacturer's service options carefully. Take note of their response times and availability of technicians. Timely support can prevent prolonged downtime.

Maintenance is equally important. A machine that requires frequent repairs can disrupt production schedules. Investigating the average lifespan of components might offer insights. How easy is it to source replacements? Not all machines come with comprehensive manuals. Some may rely on technical support that is not always accessible.

Additionally, consider training resources offered by the manufacturer. Proper training can drastically reduce operation errors. But not all companies provide adequate training support. Reflect on your team's expertise level. If they lack experience, it might be a red flag. Be mindful of how this can impact your investment. Always assess these elements critically to make an informed decision.