In the rapidly evolving world of packaging and manufacturing, the demand for high-quality PET Coating Machines has surged as businesses strive to enhance their product durability and aesthetic appeal. PET, or polyethylene terephthalate, provides exceptional resistance to moisture, chemicals, and UV rays, making it an ideal choice for various applications. As a result, investing in the right PET Coating Machine can significantly impact the quality of your products and the efficiency of your production processes.

This article aims to provide a comprehensive overview of the top five PET Coating Machines that are poised to make a difference in your business by 2025. By exploring the most innovative and efficient machines in the market, we will highlight their key features, advantages, and how they can cater to your specific needs. Whether you are looking to upgrade your current equipment or are entering the packaging industry for the first time, understanding the latest advancements in PET coating technology will empower you to make informed decisions that drive your business forward. Understanding these machines will not only enhance your efficiency but also elevate the quality of the products you offer to your customers.

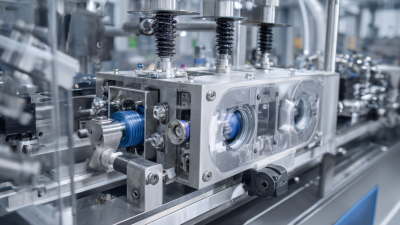

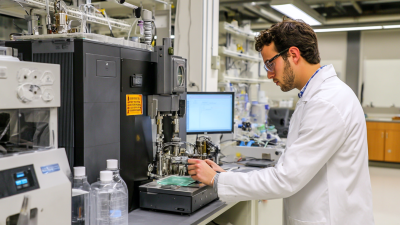

When considering the top PET coating machines for 2025, several key features stand out that can significantly enhance your business operations. Firstly, advanced automation technology is essential. Machines equipped with AI-driven systems can optimize production speed and minimize human error, ensuring consistent and high-quality finishes. Additionally, machines with integrated real-time monitoring capabilities allow for immediate adjustments and maintenance alerts, reducing downtime and improving efficiency.

Another crucial feature is flexibility in coating materials and processes. Leading PET coating machines now come with the ability to handle various substrates and apply multiple coating types, including eco-friendly options. This versatility enables businesses to adapt to changing market demands and sustainability practices without investing in additional equipment. Furthermore, improved energy efficiency in these machines not only helps in lowering operational costs but also aligns with global initiatives for environmentally sustainable manufacturing. By focusing on these key features, businesses can stay competitive and responsive in the evolving landscape of PET coating technology.

The future of PET coating equipment is being shaped by several innovative technologies that focus on enhancing efficiency, sustainability, and performance. According to a recent report by MarketsandMarkets, the global PET coating machines market is projected to reach $250 million by 2025, driven by an increasing demand for high-quality packaging solutions in industries such as food and beverages, pharmaceuticals, and consumer goods. As companies seek to improve their operational capabilities, the adoption of advanced technology integrations, such as IoT and automation, will become increasingly prevalent.

One significant advancement lies in the development of eco-friendly coatings that reduce the environmental footprint of packaging processes. Research from Smithers Pira indicates that the demand for sustainable packaging is expected to grow by 20% annually, highlighting the necessity for manufacturers to invest in PET coating technologies that align with environmental standards. Moreover, the integration of AI-powered systems helps in optimizing production lines, reducing waste, and improving overall quality control. As businesses evolve, these technologies will not only enhance product performance but also foster sustainable practices that meet consumer demands for environmentally responsible products.

| Machine Model | Coating Speed (m/min) | Coating Thickness (microns) | Energy Consumption (kW) | Features |

|---|---|---|---|---|

| Model A | 120 | 10-30 | 15 | Automatic adjustment, High efficiency |

| Model B | 100 | 5-25 | 10 | User-friendly interface, Low maintenance |

| Model C | 150 | 15-35 | 20 | Integrated control system, Smart monitoring |

| Model D | 80 | 8-20 | 12 | Compact design, Cost-effective |

| Model E | 130 | 12-28 | 18 | Versatile options, Energy efficient |

In the competitive landscape of PET coating machinery, efficiency is paramount for businesses looking to enhance their production capabilities. Recent reports highlight that the global demand for PET coating machines is expected to grow at a CAGR of 5.3% from 2023 to 2028, driven by advancements in technology and the increasing need for sustainable packaging solutions. Companies must focus on selecting machines that not only optimize production speed but also minimize waste and energy consumption.

When assessing the top PET coating machines available in 2025, features such as automation, precision coating, and user-friendly interfaces stand out. For instance, the latest models incorporate smart technology that allows for real-time monitoring and adjustments, significantly reducing downtime. Industry data indicates that businesses utilizing these advanced machines can achieve up to 20% higher throughput, emphasizing the importance of investing in reliable and efficient equipment. Therefore, understanding the efficiency metrics of these machines is crucial for manufacturers aiming to stay ahead in the ever-evolving market.

When selecting the right PET coating machine for your business, it's crucial to consider several key factors that impact the overall efficiency and profitability of your production process. According to a recent report by Smithers Pira, the global market for PET coatings is expected to reach $4.5 billion by 2025, highlighting the growing demand for quality and performance in coated products. Understanding this trajectory will help businesses align their equipment choices with market trends, ensuring they stay competitive.

One essential aspect to consider is the machine’s compatibility with existing production lines and material specifications. A study by Technavio noted that innovations in machine technology have led to improvements in both speed and precision, factors that directly influence operational costs. Additionally, choosing a machine with advanced features such as real-time monitoring and automation capabilities can enhance productivity while reducing waste. In an industry that thrives on efficiency, selecting the right PET coating machine is not just a matter of preference; it can be a strategic decision that significantly influences your business's success in a rapidly evolving market.

Investing in PET coating technologies is a strategic decision for businesses looking to enhance their product offerings and operational efficiency in 2025. Recent industry reports indicate that the PET coating market is projected to grow significantly, with an expected CAGR of 6.2% from 2023 to 2028. This growth is driven by increased demand in sectors such as packaging, automotive, and electronics, as companies strive for lightweight and durable protective solutions.

**Tips:** When considering an investment in PET coating machines, conduct a thorough cost-benefit analysis. Evaluate not only the initial purchase price but also maintenance costs and potential savings from improved production efficiency. Additionally, assess the supplier's reputation and after-sales support, as these factors can greatly influence the long-term success of your investment.

Moreover, the long-term sustainability aspect of PET coatings cannot be ignored. As consumers increasingly demand environmentally friendly products, businesses that adopt such technologies could gain a competitive edge. According to a recent survey, approximately 75% of consumers are willing to pay more for sustainable products, highlighting the economic incentive behind investing in advanced PET coating solutions.

**Tips:** Stay updated on the latest innovations in PET coatings. Regularly attending industry conferences and workshops can provide valuable insights and networking opportunities that may lead to better investment decisions.

This chart represents the cost-benefit analysis of the top 5 PET coating machines in 2025 based on key parameters such as initial investment, operational costs, and estimated annual profits. The data reflects why investing in these technologies is essential for businesses looking to enhance their production efficiency.