In the ever-evolving landscape of renewable energy, Hydrogen Fuel Coating Machines have emerged as a crucial innovation, paving the way for sustainable solutions and enhanced energy efficiency. Industry expert Dr. Emily Tran, a leading researcher in hydrogen technologies, emphasizes the importance of these machines by stating, "Harnessing the power of hydrogen through advanced coating technology is not just a step forward; it's a leap towards a cleaner, more sustainable future."

As we explore the top five Hydrogen Fuel Coating Machines for 2025, we delve into the cutting-edge developments that these systems bring to the hydrogen sector. These machines not only improve the durability and efficiency of fuel cells but also contribute to the broader goal of transitioning to a hydrogen-based economy. With a focus on innovation and sustainability, the featured machines represent the forefront of technology that is shaping the future of clean energy solutions.

This detailed assessment of the leading Hydrogen Fuel Coating Machines will provide insights into their functionalities, capabilities, and the pivotal role they play in advancing hydrogen as a viable energy source. Join us as we uncover the top contenders making significant strides in this vital industry.

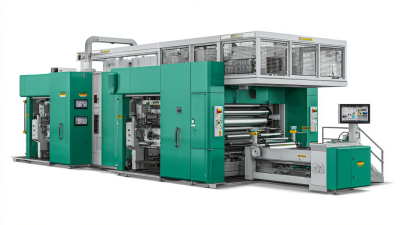

As the demand for renewable energy sources continues to rise, hydrogen fuel coating machines are becoming a pivotal technology in the energy sector. According to a recent market research report by Allied Market Research, the global hydrogen market is expected to reach USD 199.1 billion by 2025, reinforcing the significance of advanced coating technologies. These machines enhance fuel cell performance by improving the durability and efficiency of fuel cells through innovative coatings. The top technologies for hydrogen fuel coating machines in 2025 are predicted to focus on precision application methods and sustainable materials, which are essential for achieving more efficient energy solutions.

In particular, advancements in plasma coating and laser cladding techniques are expected to dominate the market. Plasma coating allows for a uniform application of coatings with enhanced adhesion properties, which can effectively withstand harsh operating conditions. Meanwhile, laser cladding technology provides the ability to modify the surface of existing fuel cell components, thereby extending their lifespan and improving performance. Industry analysts estimate that the adoption of these technologies will lead to an increase in the overall efficiency of hydrogen fuel cells by upwards of 30%, making hydrogen a more viable option in the global energy landscape.

When considering hydrogen fuel coating equipment, several key features should be prioritized to ensure efficiency and effectiveness in energy solutions. A robust manufacturing process is essential to enhance the performance and durability of hydrogen technologies. Innovations in metal-organic framework catalysts can play a crucial role in improving energy generation. Thus, it’s vital to look for machines that can accommodate advanced materials that optimize the deployment of these catalysts.

Additionally, the development of prototypes for innovative coatings is paramount. These prototypes aim to address challenges related to hydrogen pipelines, such as minimizing leakage and maximizing safety. As the shift towards green hydrogen progresses, particularly in light of recent initiatives worldwide, manufacturers should seek coating machines that are compatible with the evolving demands of hydrogen storage and transport. Investing in state-of-the-art coating technologies will not only facilitate the transition to cleaner energy solutions but also contribute significantly to reducing production costs, enhancing the overall economic viability of hydrogen energy systems.

The hydrogen fuel coating market is evolving rapidly, driven by innovations aimed at enhancing the efficiency and cost-effectiveness of fuel cells. A key player in this sector, Impact Coatings, has recently delivered an advanced cost-efficient coating solution to a prominent fuel cell manufacturer under a substantial supply agreement. This development underscores the importance of innovative coating technologies in the optimization of fuel cell performance, particularly for applications in the hydrogen tanks market.

Moreover, the comparative analysis of leading hydrogen fuel coating solutions reveals varied approaches and technologies that companies adopt to improve energy solutions. As research progresses, particularly in domains such as modeling solid oxide fuel cells and advancements in electrolyzer systems for green hydrogen production, the integration of these technologies with efficient coating solutions is becoming increasingly vital. The industry's focus on sustainable hydrogen production alongside improved coating techniques is reshaping the landscape for future energy solutions, emphasizing the need for ongoing technological innovation and collaboration.

| Feature | Machine A | Machine B | Machine C | Machine D | Machine E |

|---|---|---|---|---|---|

| Output Capacity (kg/h) | 150 | 120 | 200 | 180 | 160 |

| Coating Thickness (µm) | 5 | 7 | 6 | 4 | 5 |

| Energy Efficiency (%) | 92 | 88 | 95 | 90 | 89 |

| Weight (kg) | 350 | 420 | 300 | 380 | 360 |

| Price (USD) | 250,000 | 210,000 | 300,000 | 275,000 | 260,000 |

The impact of hydrogen fuel coating innovations on energy efficiency is becoming increasingly significant as industries strive for sustainable solutions. Hydrogen fuel coatings enhance the performance of various energy applications by providing improved energy conversion rates and reduced losses during energy transfer. These advancements not only optimize energy generation processes but also extend the lifespan of energy systems, contributing to a more sustainable energy landscape.

Incorporating hydrogen fuel coating technologies can lead to remarkable reductions in energy consumption, especially in sectors like transportation, power generation, and manufacturing. By enabling better thermal management and decreasing friction and wear in engines and turbines, these coatings help maximize the efficiency of hydrogen as an energy carrier. As companies adopt these innovative solutions, the transition toward cleaner energy systems accelerates, ultimately supporting global efforts to reduce carbon emissions and combat climate change.

As the global demand for sustainable energy solutions continues to grow, hydrogen coating technologies are emerging as a pivotal advancement in the field. These innovative methods enhance the durability and efficiency of hydrogen fuel cells, making them increasingly viable for various applications. By integrating advanced materials and novel processes, manufacturers are developing hydrogen coating machines that significantly improve performance metrics such as energy output and stability under varying environmental conditions.

Future trends indicate a shift towards automation and precision engineering in hydrogen coating technologies. Machine learning algorithms and AI-driven processes are expected to streamline operations, allowing for real-time adjustments to coating applications tailored to specific substrates. The emphasis on eco-friendly materials is also gaining momentum, fostering the development of coatings that not only meet performance standards but also minimize ecological impact. Innovations in nanotechnology are anticipated to lead to further breakthroughs, enhancing the effectiveness and sustainability of hydrogen fuel systems, ultimately supporting a greener energy future.