In the competitive landscape of manufacturing and production, the choice of equipment can significantly impact operational efficiency and product quality. A recent report by MarketsandMarkets indicates that the global coating equipment market is projected to reach $27 billion by 2026, highlighting the growing importance of innovative solutions such as the Small Coating Machine. These machines are designed for versatility and precision, serving small to medium-sized businesses that require flexible coating applications without the bulk of larger industrial machines. By carefully selecting the right Small Coating Machine, businesses can enhance their productivity, reduce waste, and ultimately improve their bottom line. In this ultimate guide, we will provide a comprehensive checklist to aid you in making an informed decision that aligns with your specific operational needs.

When selecting a small coating machine for your business, understanding your specific needs is paramount. According to a recent report by Smithers Pira, the global market for coating machines is projected to grow at a CAGR of 4.2% from 2022 to 2027. This growth is driven by an increasing demand for higher quality coatings in various sectors, including automotive, electronics, and consumer goods. Therefore, assessing the types of applications and the desired output quality will play a crucial role in making an informed decision.

Another critical consideration is the machine's compatibility with existing production processes. A study by Technavio highlights that the integration capabilities of coating machinery have become a top priority for manufacturers, with 56% indicating that ease of integration directly influences their purchase decisions. Evaluating how a small coating machine fits into your manufacturing workflow can lead to improved efficiency and reduced operational costs. By taking these factors into account, businesses can select the optimal coating solution tailored to their needs, ensuring better productivity and profitability in an increasingly competitive market.

This chart illustrates the key considerations when selecting a small coating machine for your business, based on business needs and specific features.

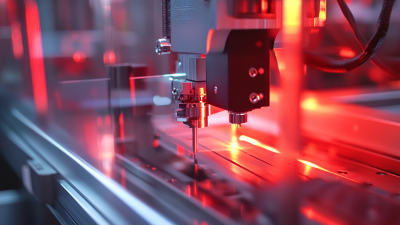

When selecting a small coating machine for your business, it is crucial to focus on key features that will enhance operational efficiency and output quality. One of the most significant aspects is the machine's versatility in handling different types of coatings. With the global optical coating equipment market projected to reach USD 3.81 billion by 2030, businesses are increasingly searching for machines that can handle a variety of coating substances, including advanced materials like titanium dioxide nanoparticles. These low-cost suspensions can improve surface quality and are gaining traction in industries that demand precision, such as electronics and 3D printing.

Another essential feature is the machine's automation capabilities. With advancements in technology, automatic coating machines are becoming the norm, as they reduce labor costs and increase production speed. Reports indicate that the cerakote market is anticipated to grow at a CAGR of 7.8% from 2025 to 2034, highlighting the growing demand for automated systems that offer consistent application and improve overall product integrity. Look for machines that integrate modern processing technologies and provide detailed diagnostics to maintain quality control and minimize downtime throughout the manufacturing process.

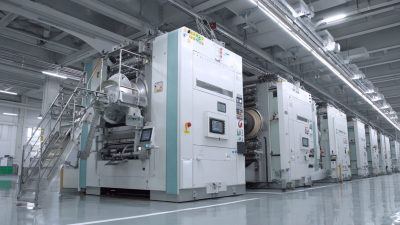

When selecting a small coating machine for your business, it is crucial to understand the various types available and their respective advantages and disadvantages. For instance, electrostatic coating machines are known for their efficiency and high transfer rates, often exceeding 90%. According to industry reports, this technology can reduce material waste while providing a uniform finish, making it ideal for companies aiming for sustainability. However, the initial investment can be higher compared to conventional spray equipment, which might deter small businesses with budget constraints.

On the other hand, conventional spray coating machines are typically more affordable and easier to maintain. They offer flexibility in application but at the cost of higher overspray and material waste—often around 30-40%. This can impact both the bottom line and environmental footprint. Advanced options like automatic coating machines have emerged as well, providing precision and repeatability, but also require a substantial upfront investment and skilled workforce for operation. As per a recent industry analysis, the market for automatic coating solutions is projected to grow by 15% annually, indicating a shift towards efficiency-focused technology in small to medium enterprises.

When budgeting for a small coating machine, it's essential to consider both the upfront costs and long-term expenses. Initial purchase prices can vary widely based on the machine's specifications, functionality, and brand. On average, smaller, entry-level machines might range from $5,000 to $20,000, while more advanced models with enhanced features can cost significantly more. It's crucial to conduct thorough research and choose a machine that not only fits within your budget but also meets your business's specific needs.

In addition to the purchase price, consider other financial aspects such as maintenance, operation costs, and potential downtime. Regular maintenance will ensure your machine runs efficiently, thus avoiding costly repairs in the future. Further, evaluate the cost of consumables and materials required for the coating process, as these can impact your overall budget. By taking the time to assess these factors, you can make informed decisions that lead to a better return on investment over the life of your small coating machine.

When investing in a small coating machine, maintenance is crucial for maximizing its lifespan and enhancing operational efficiency. According to a report by the Machinery Maintenance Association, proper upkeep can extend the life of industrial machinery by 20-30%. Regular cleaning, lubrication, and inspection are key practices that help mitigate wear and tear. Dust and residue can accumulate over time, leading to inefficient performance and potential breakdowns. Therefore, setting up a consistent maintenance schedule is essential for small businesses looking to protect their investments.

Additionally, considering that downtime can cost companies an average of $2 million per year in lost productivity (as reported by the Advanced Manufacturing Office), prioritizing maintenance becomes not just a budgetary concern, but a strategic necessity. Technicians recommend conducting preventive maintenance every 500 operational hours or at least quarterly, depending on usage. Simple tasks such as replacing worn seals, checking electrical connections, and calibrating the machine can greatly reduce the risk of unexpected failures, ensuring that your coating machine operates smoothly and reliably for years to come.