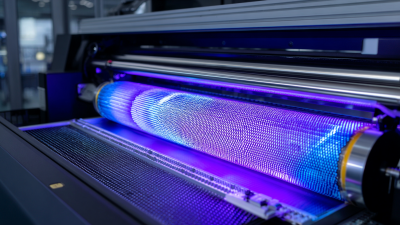

In recent years, the printing and finishing industry has witnessed a significant shift towards the utilization of UV Coating Machines, primarily due to their ability to enhance the durability and aesthetic appeal of printed materials. According to a report by Smithers Pira, the global market for UV coatings is projected to reach $5.5 billion by 2025, driven by increased demand for high-quality finishings in various applications such as packaging, commercial printing, and promotional materials. As manufacturers aim to streamline their operations and improve product quality, the importance of understanding the benefits and proper techniques related to UV Coating Machines becomes paramount.

Renowned industry expert Dr. Emily Chen, a leading authority in printing technologies, asserts, "The adoption of UV Coating Machines not only enhances the visual appeal of products but also significantly improves their resistance to wear and environmental factors." This sentiment underscores the necessity for businesses to not only invest in advanced coating technologies but also to educate themselves on optimal usage practices. By harnessing the full potential of UV Coating Machines, companies can not only elevate their product offerings but also gain a competitive edge in an increasingly saturated market. This guide aims to illuminate the key benefits of UV Coating Machines and provide practical tips for their optimal use, ensuring that industry players can make informed decisions that align with their operational goals.

UV coating machines have become vital tools for modern printing businesses, offering a range of benefits that enhance the quality and durability of printed products. According to a recent Smithers report, the UV printing market is projected to grow at a compound annual growth rate (CAGR) of 8.3% through 2025, driven by increasing demand for high-quality finishes and sustainable printing options. UV coating not only provides a visually appealing gloss or matte finish, but it also significantly enhances physical resistance to scratches, scuffs, and moisture, making it ideal for both consumer and commercial applications.

To maximize the effectiveness of UV coating machines, businesses should consider implementing a few key tips. First, ensure proper substrate compatibility by conducting thorough testing across different materials to find the best matches for UV coatings. Second, regular machine maintenance is crucial; keeping the UV lamp clean and ensuring optimal curing conditions can dramatically affect the finish quality. Lastly, experimenting with various coating formulations can lead to unique textural effects and finishes that set products apart in a competitive market.

By utilizing UV coating technology and following these essential tips, printing businesses can enhance their offerings and better meet the evolving demands of their customers.

When selecting a UV coating machine, it’s crucial to consider several essential features that directly impact performance and efficiency. One of the most significant aspects is the machine’s curing speed. According to a recent industry report by Smithers Pira, improvements in UV curing technology can reduce drying times by up to 50%, enabling faster production cycles and increased output. This feature not only enhances workflow but also allows businesses to meet tight deadlines more effectively.

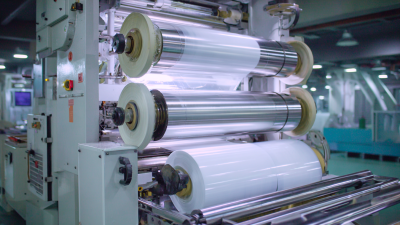

Another important feature is the machine's versatility in handling different substrates. A UV coating machine that can accommodate a variety of materials, from paper to plastics and metals, is invaluable for businesses looking to diversify their product offerings. Additionally, monitoring the machine’s energy efficiency is key; machines equipped with advanced LED UV technology can lower energy consumption by as much as 70% compared to traditional UV systems, making them both a cost-effective and environmentally friendly option. By focusing on these essential features, business owners can make informed decisions that optimize their UV coating processes and drive better returns on investment.

Setting up your UV coating machine is essential for achieving optimal results and boosting productivity. Start by carefully reading the manufacturer's manual to understand the specific requirements and features of your machine. Ensure that the machine is positioned on a stable, level surface away from direct sunlight to prevent any interference during the coating process. Before powering up, check that all components, including the UV lamp and rollers, are properly installed and in good condition.

Once the machine is set up, calibrate the settings based on the type of substrate you’ll be using. Adjust the speed and pressure according to the thickness and texture of the material to ensure an even application of the UV coating. It’s crucial to run test samples before starting a large production run. This allows you to fine-tune the settings to achieve the best finish and avoid costly mistakes. Regular maintenance checks and cleaning of the machine will also prolong its lifespan and maintain consistent quality in your coatings.

Maintaining UV coating equipment is essential for ensuring consistent quality and longevity. According to a report from the Printing Industries of America, regular maintenance can increase the lifespan of UV coating machines by up to 40%. To achieve optimal performance, operators should implement a routine maintenance schedule that includes cleaning the UV lamps and rollers, inspecting electrical components, and checking the condition of the coating materials. Keeping a log of maintenance activities can help identify recurring issues and streamline future servicing.

Proper storage of UV coatings is another critical factor in equipment longevity. Over time, exposure to light and air can lead to the degradation of these materials, resulting in poor application quality and increased wear on the machinery. A study by the National Association of Print Manufacturers emphasized that storing UV coatings in a cool, dark environment can significantly extend their shelf life—potentially by as much as 50%. Additionally, using high-quality coatings that are compatible with your specific equipment can prevent clogging and reduce maintenance needs, thus optimizing your overall operation.

When dealing with UV coating processes, troubleshooting common issues is essential for maintaining high-quality results. One of the most frequent problems encountered is improper adhesion of the coating to the substrate. This can result from insufficient surface preparation or contamination. Ensuring that surfaces are meticulously cleaned and primed can enhance the bonding strength significantly. Processors should also monitor the UV curing time and intensity, as inadequate curing can lead to tackiness or incomplete film hardness.

Another prevalent issue is the presence of surface defects such as bubbles or orange peel, which can negatively impact the final appearance. These flaws often arise from improper application techniques or incorrect viscosity of the coating material. It is crucial to adjust the parameters of the coating machine accordingly and consider the environmental conditions affecting the application. Keeping a close eye on humidity and temperature levels while applying UV coatings can help mitigate these issues. By troubleshooting these common challenges effectively, users can ensure a smoother UV coating process and achieve optimal results.

| Benefit/Tips | Description | Common Issues | Troubleshooting Steps |

|---|---|---|---|

| Enhanced Durability | Protects printed materials from scratches and wear. | Uneven coating | Adjust the speed of the substrate passing through the machine. |

| Quick Drying | UV coating dries instantly, increasing production speed. | Inadequate curing | Check UV lamp intensity and replace if necessary. |

| Glossy Finish | Provides a high-quality finish that enhances color depth. | Dust and debris on surface | Ensure a clean working environment before coating. |

| Eco-Friendly Options | Reduced VOCs compared to traditional coatings. | Poor adhesion | Increase surface energy with primers or treatments. |

| Versatility | Compatible with various substrates and finishes. | Yellowing over time | Select high-quality UV coatings and limit exposure to sunlight. |